12

Fault finding

Greenstar FS CDi

ErP

– 6720919078 (2015/12)

6.1 Error codes 6.2 Extreme cold weather

In some instances where the condensate pipe work is run

externally or in an unheated area, such as a garage, the

condensate pipe work can be at risk of freezing, even if well

insulated.

A frozen/blocked condensate pipe will cause the boiler to shut

down.

If the condensate pipe has frozen:

▶ Locate the blockage.

It is likely that the pipe is frozen at the most exposed point

outside the building or where there is an obstruction to

flow.

This could be the open end of the pipe, at a bend or elbow,

or where there is a sag in the pipe in which condensate can

collect.

The location of the blockage should be identified as closely

as possible before taking further action.

▶ Thaw the frozen pipe.

The pipe can be thawed by applying a hot water bottle, a

microwaveable heating pack (the sort used for muscular

aches and pains) or a cloth soaked in hot water to the

exterior of the pipe, close to the point of blockage.

Hot water, but not boiling, can also be poured onto the pipe

from a watering can or similar container.

▶ Once the pipe has been thawed the boiler must be reset,

press the reset button for five seconds and wait two to

three minutes for the boiler to restart.

▶ If the boiler does not restart, contact Worcester, Bosch

Group Appointments Team (see back cover for details).

▶ Contact your installer in order to find a permanent solution

to the problem.

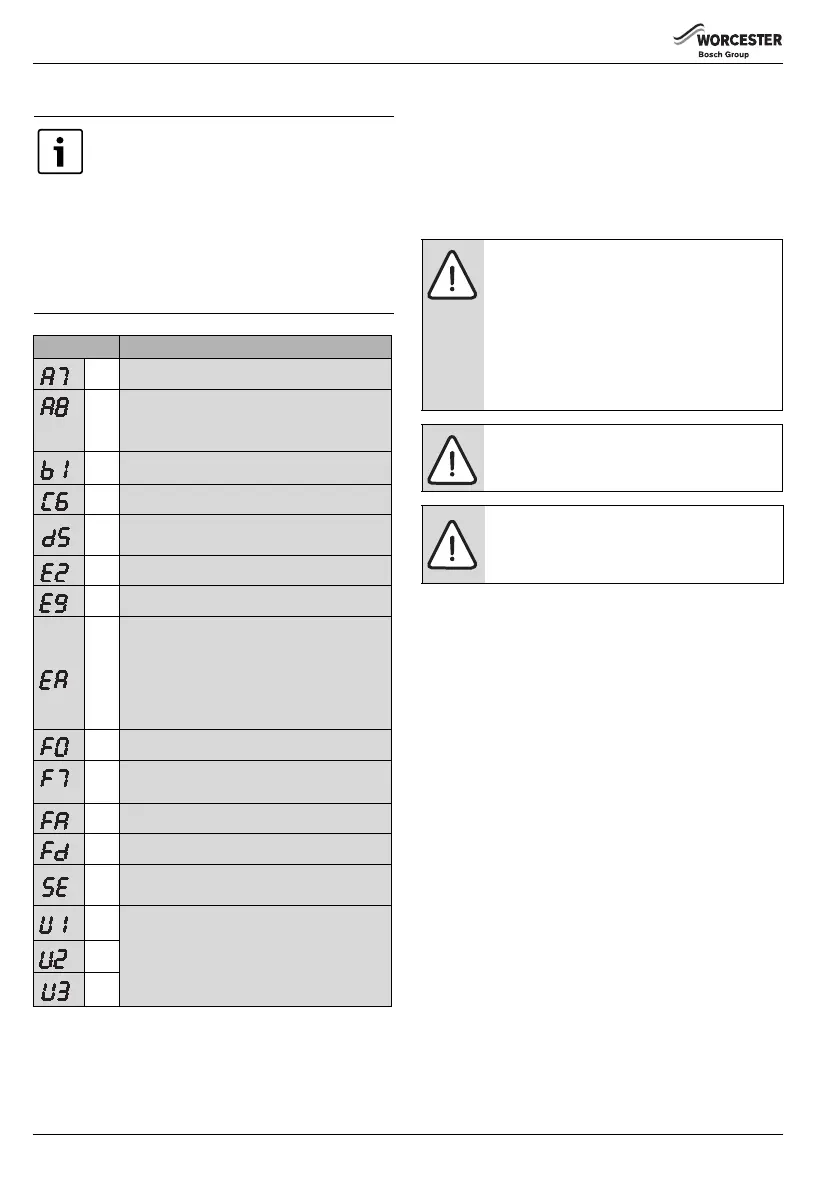

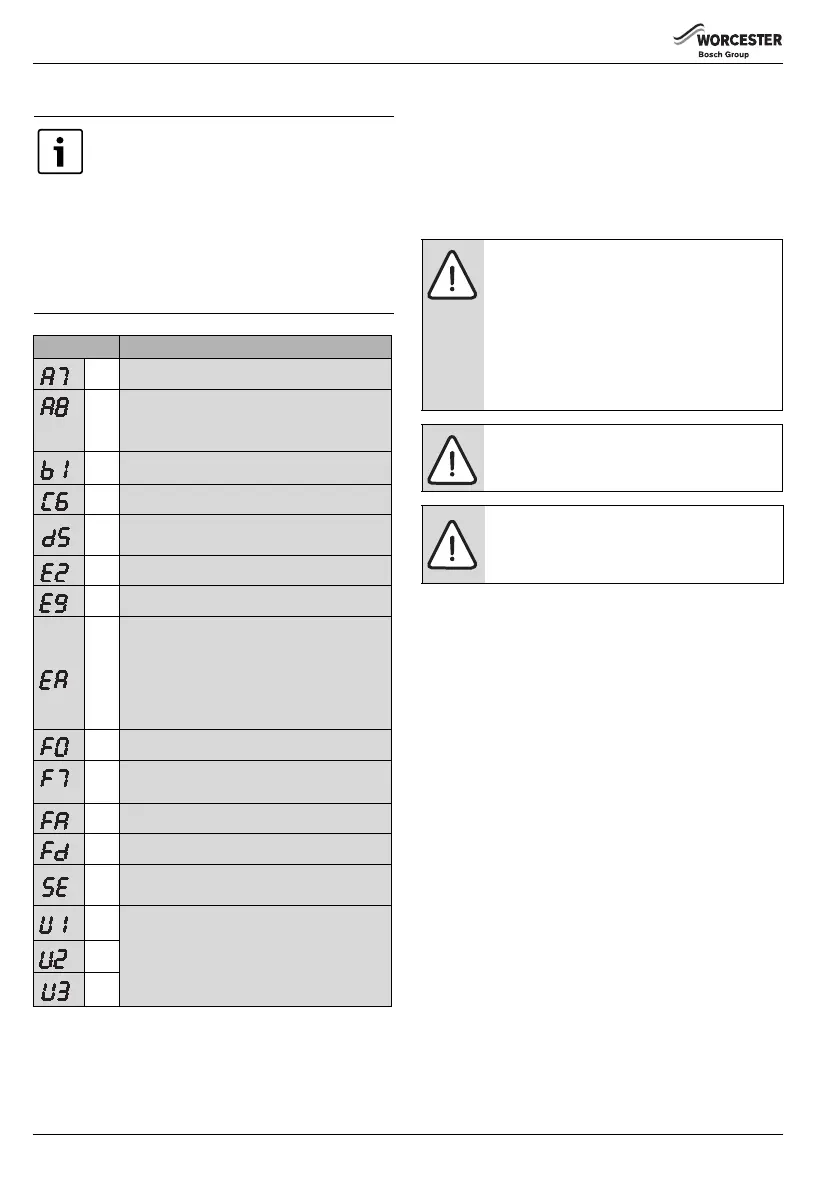

When calling Worcester, Bosch Group, you

may be asked for the error code. This Table is

for you to help identify the possible cause of

the fault.

▶ Do not try to rectify any of the faults listed

below by yourself.

▶ Contact a Worcester, Bosch Group service

engineer, or other Gas Safe registered

engineer.

Error code Description

A7 Hot water NTC sensor defective.

A8 Break in communication to weather

compensating clip-in control or Greenstar

Comfort II RF

b1 Code plug not detected.

C6 Fan speed too low.

d5 Condensate pump fault

E2 CH flow NTC sensor defective.

E9 Safety temp. limiter in CH flow has tripped.

EA Flame not detected.

Check, if it is safe to do so:

• if gas is on in the house

• for frozen condensate pipe

• for blocked flue outlet

F0 Internal error.

F7 Flame detected even though boiler switched

off.

FA Flame detected after gas shut off.

Fd Reset button pressed by mistake.

SE Service required

U1 Boiler flow temperature is too high,

the boiler will shut down until it has cooled

down

U2

U3

WARNING: Falling hazard!

Failure to follow this guidance may result in

personal injury.

▶ Only attempt to thaw a condense pipe that

is at ground level, and that is easily

accessible.

▶ Never attempt to thaw a condense pipe

that is at height.

CAUTION: Pipe damage

▶ DO NOT use boiling water to thaw the

condensate pipe!

CAUTION: Slip hazard

▶ Ensure that the subsequent freezing of any

water does not result in a slip hazard

Loading...

Loading...