PRE-INSTALLATION

6 720 804 532 (2012/09) 11

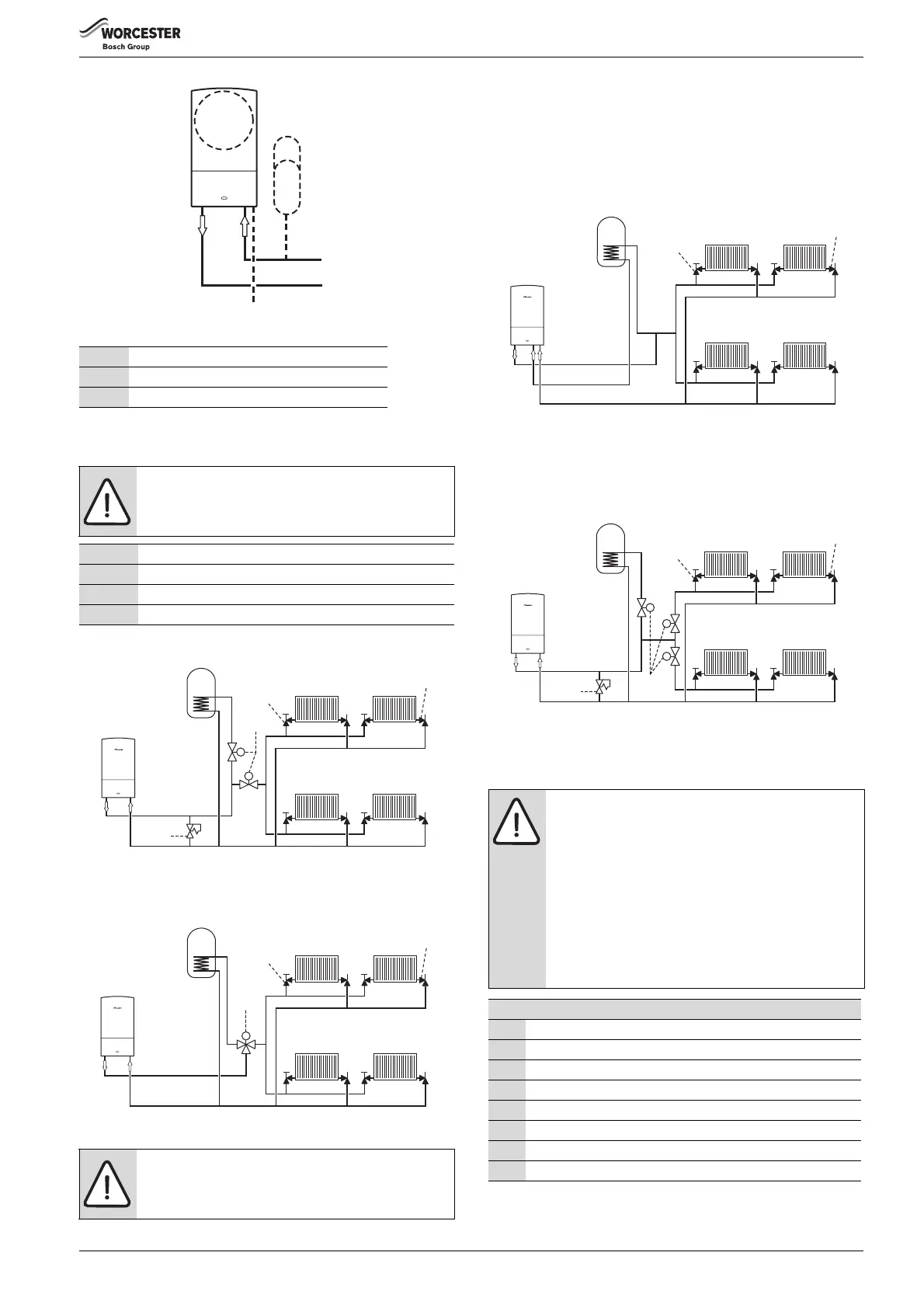

Fig. 5 Additional expansion vessel

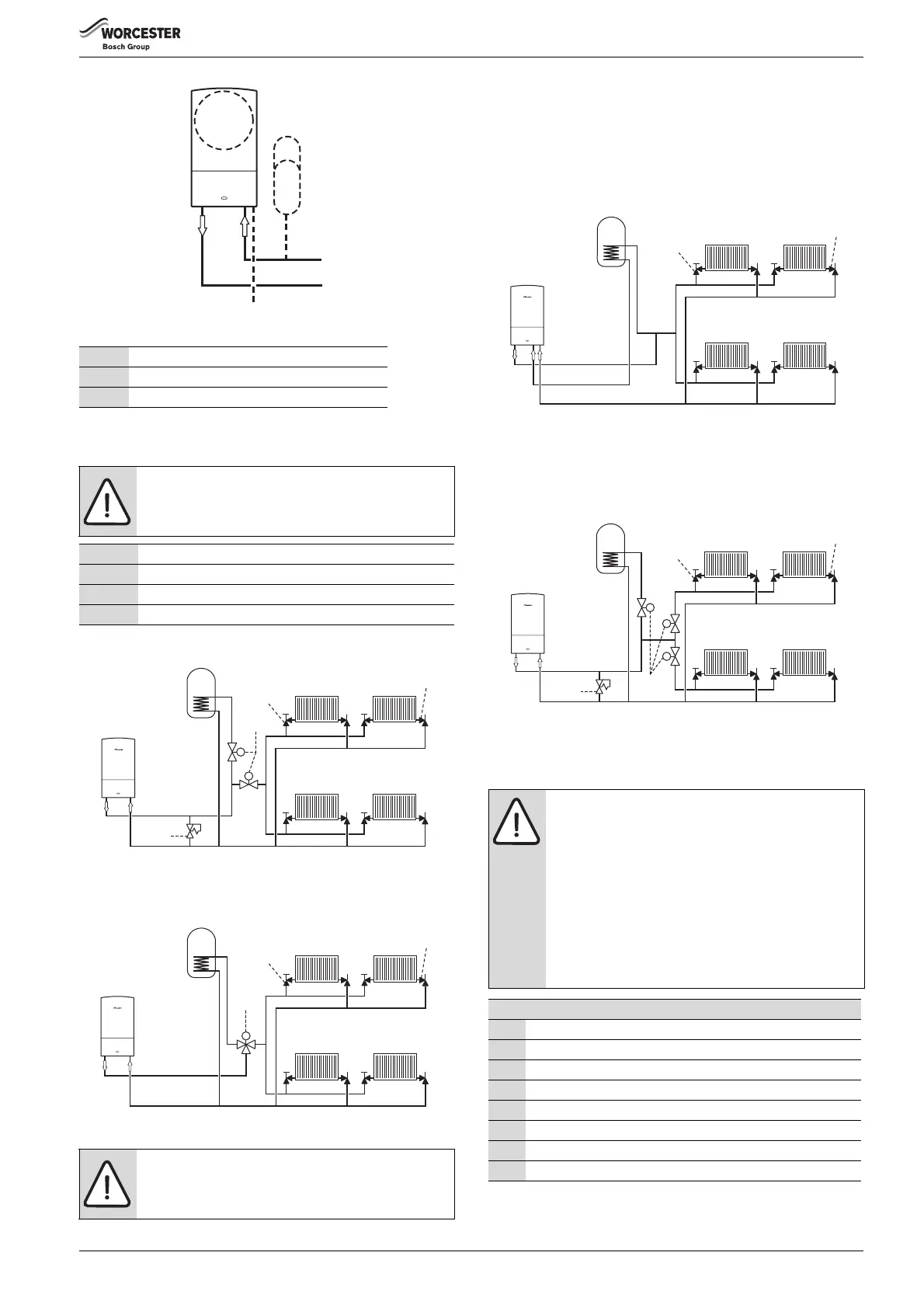

EXISTING BUILDS: S AND Y PLAN SYSTEMS:

S PLAN LAYOUT

Fig. 6 Existing build - S Plan

Y PLAN LAYOUT WITH EXTERNAL DIVERTER VALVE

Fig. 7 Existing build - Y Plan external diverter valve

OPTIONAL DIVERTER VALVE

This boiler is designed to operate on a sealed system only. The boiler will

require a second return pipe from the water cylinder to the wall

mounting frame and terminate in 15mm copper pipe.

EXISTING BUILD - SYSTEM LAYOUT WITH OPTIONAL INTERNAL

DIVERTER VALVE (NOT SUPPLIED WITH BOILER)

Fig. 8 Existing build - Internal diverter valve

NEW BUILD - TWO ZONED HEATING SYSTEM

The latest Part L1a regulation for new installations require separate zone

controls for the central heating.

Fig. 9 New build - System layout

3.4 CONDENSATE PIPE WORK

1 Appliance expansion vessel - CH

2 Extra expansion vessel - CH return

3 Pressure relief discharge

Table 7 Key to fig. 5

NOTICE: The boiler is fitted with its own internal bypass.

1 Diverter/Zone valve

2 Radiator valve (flow)

3 Lock shield valve (return)

4Bypass

NOTICE:

▶ A drain cock should be fitted at the lowest point of the

heating circuit and beneath the appliance.

NOTICE:

▶ Where a new or replacement boiler is being installed,

access to an internal “gravity discharge” point should

be one of the factors considered in determining boiler

location.

▶ The condensate pipe must be nominally

22mm Ø plastic pipe.

▶ The condensate pipe work must fall at least 52mm per

metre towards the outlet and should take the shortest

practicable route.

▶ Ensure there are no blockages in the pipe run.

Key to condensate illustrations

1 Condensate discharge from boiler

2 Soil and vent stack

3 Minimum 450mm and up to three storeys

4 Visible air break at plug hole

5 Sink or basin with integrated overflow

6 75mm sink waste trap

7 Condensate pump

* Condensate trap of 75mm already incorporated into the boiler

Boiler flow

Cylinder return

Heating return

3

2

6720644743-07.1Wo

6720644743-42.1Wo

3

2

1

4

M

MM

Loading...

Loading...