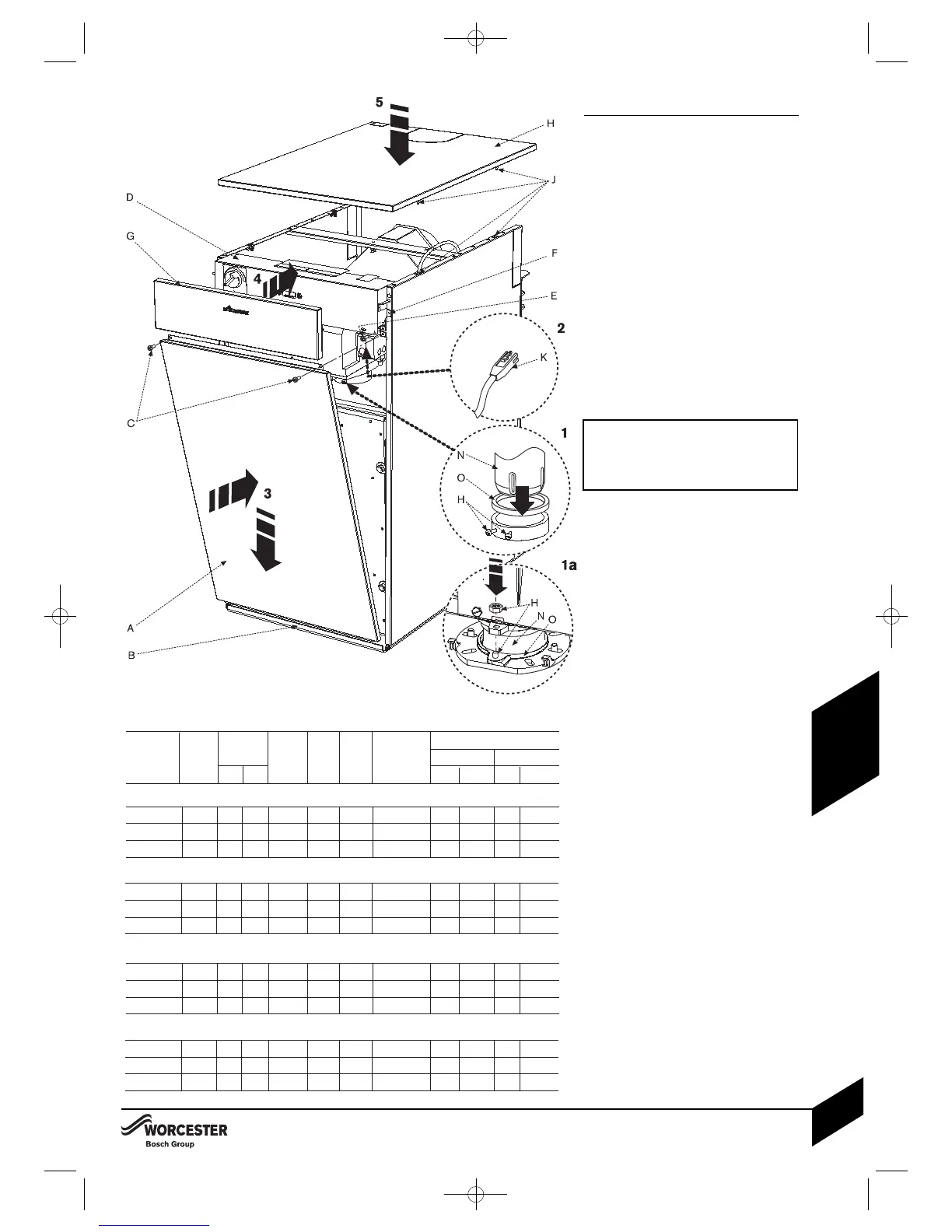

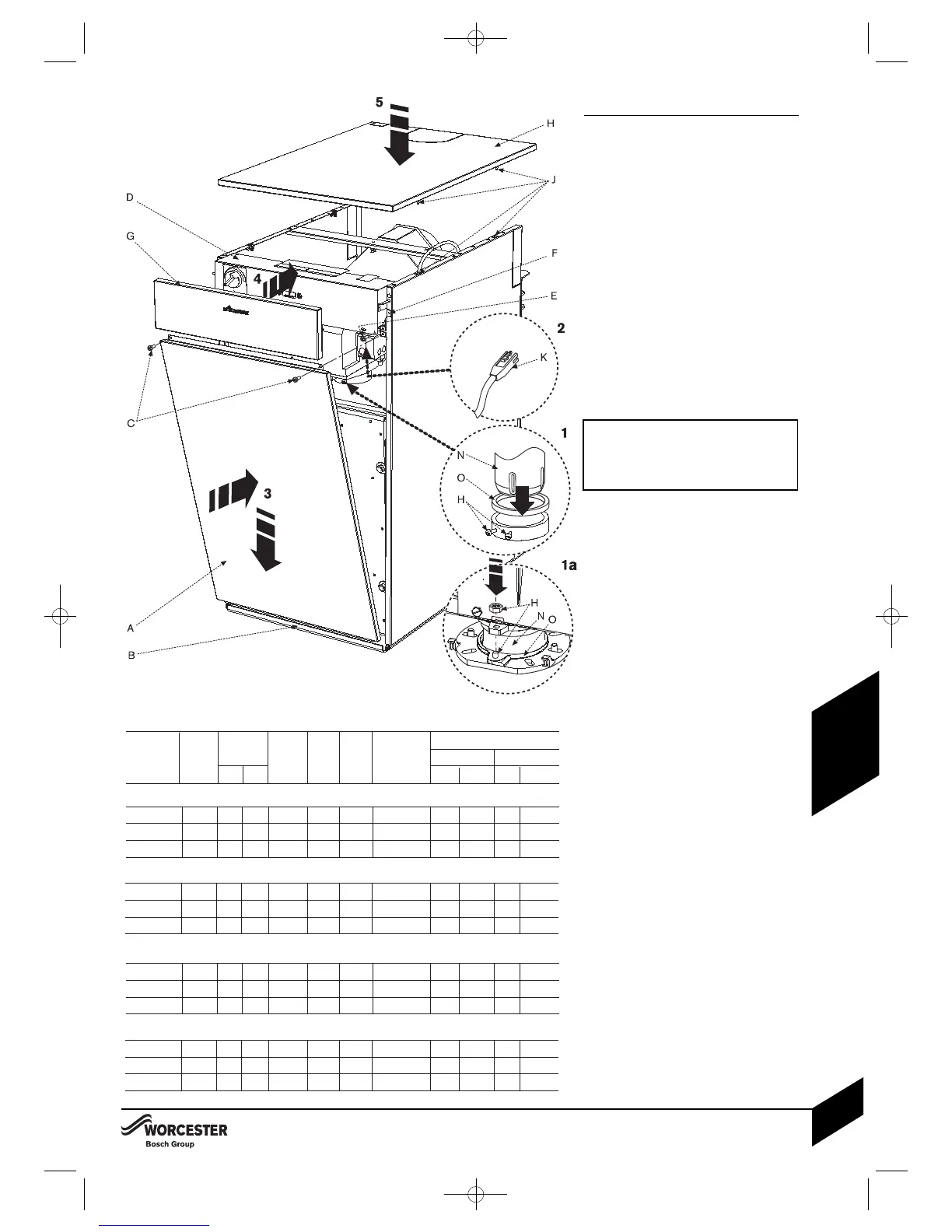

INSPECTION AND SERVICE

Fire valve:

Check that the oil supply pipe has a fire valve

fitted externally to the building with the fire

valve sensor located within the appliance

case. A fire valve sensor clip is provided for

this purpose on the casing support panel.

Re-commission the burner:

1 Sterling burner:

Align burner combustion head (N) into boiler

housing tube with gasket (O) correctly fitted.

Push firmly down to compress the gasket (O).

Tighten burner retainers (H) sufficiently to

ensure a good seal.

1aRiello burner:

Align burner combustion head (N) into

boiler housing tube flange (O).

Secure with retaining nut (H).

Tighten retaining nut sufficiently to

ensure a good seal.

IMPORTANT:

Ensure the gasket is a good seal between

the burner combustion head and the boiler

housing to prevent flue gases escaping

from the combustion chamber into the room.

2Plug burner lead (K) into control box (D).

Connect an oil pressure gauge to the oil

pump, run the burner and check the oil

pressure is correct for the required boiler

output. Check that the smoke reading is

between 0 and 1, if the smoke reading is

above 1 check the air setting. If the air

setting is correct check that the burner has

been reassembled correctly.

Allow the boiler to warm up then check the

combustion settings are correct as

indicated in the table below, adjust the

CO

2

if necessary using the air shutter.

When the combustion is correct turn off the

boiler, remove the pressure gauge and refit

the blanking plug.

Refit panels:

3Locate edge of front panel (A) onto

supporting ledge (B) on the baseplate.

Secure with screws (C).

4Slide control box (D) into the boiler.

Secure with screws (E).

Locate ball stud connectore (F) and push-fit

upper front panel (G) towards the boiler to

secure.

If the data label plate has been removed

ensure it is refitted to the appliance.

5Locate the top panel (H) onto the ball stud

connections ( J ) and press down to secure.

After service handover:

Make a note of the date of any water treatment.

Set the controls back to the users

requirements.

Complete the service interval record at the

back of this manual and a CD11 or an

equivalent form.

If the appliance is unused and exposed to

freezing conditions; shut off all the mains

supplies, isolate the boiler and drain the

system and boiler, including the secondary

heat exchanger.

Loading...

Loading...