How to fix loose impactor housing bolts on WORKMASTER GO-A8-PW Gate Opener?

- PPenny GarciaAug 21, 2025

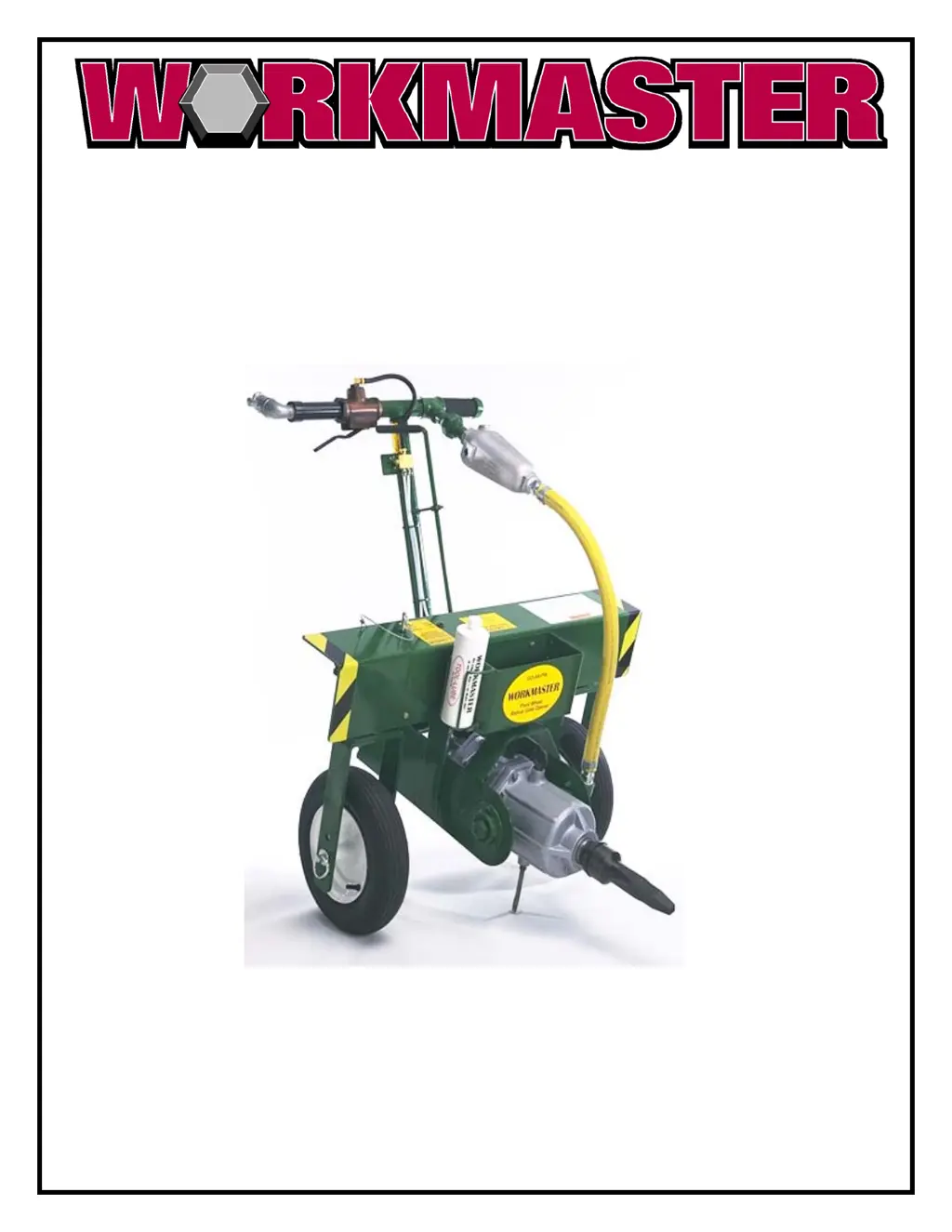

If the impactor housing bolts on your WORKMASTER Gate Opener become loose, it's likely due to vibration from impacting. To resolve this, apply Loctite to the bolts and retighten them.