13

Compact circular saw WX427

to hold down the spindle lock button (5) and attempting

to manually rotate the blade. If installed correctly, the

blade should not spin.

For best cutting results, use a saw blade suited to the

material and cut quality desired.

3. ADJUSTING THE CUTTING DEPTH

- Release the Depth Adjustment Lever (11) by lifting it

up.

- Manually push the base plate (12) up or down to the

desired depth on the scale.

- Push the Depth Adjustment Lever (11) back down to

lock the base plate at the desired depth.

- Always add 1/8” (3 mm) to the depth of cut to ensure

the blade has enough clearance to cut completely

through the material.

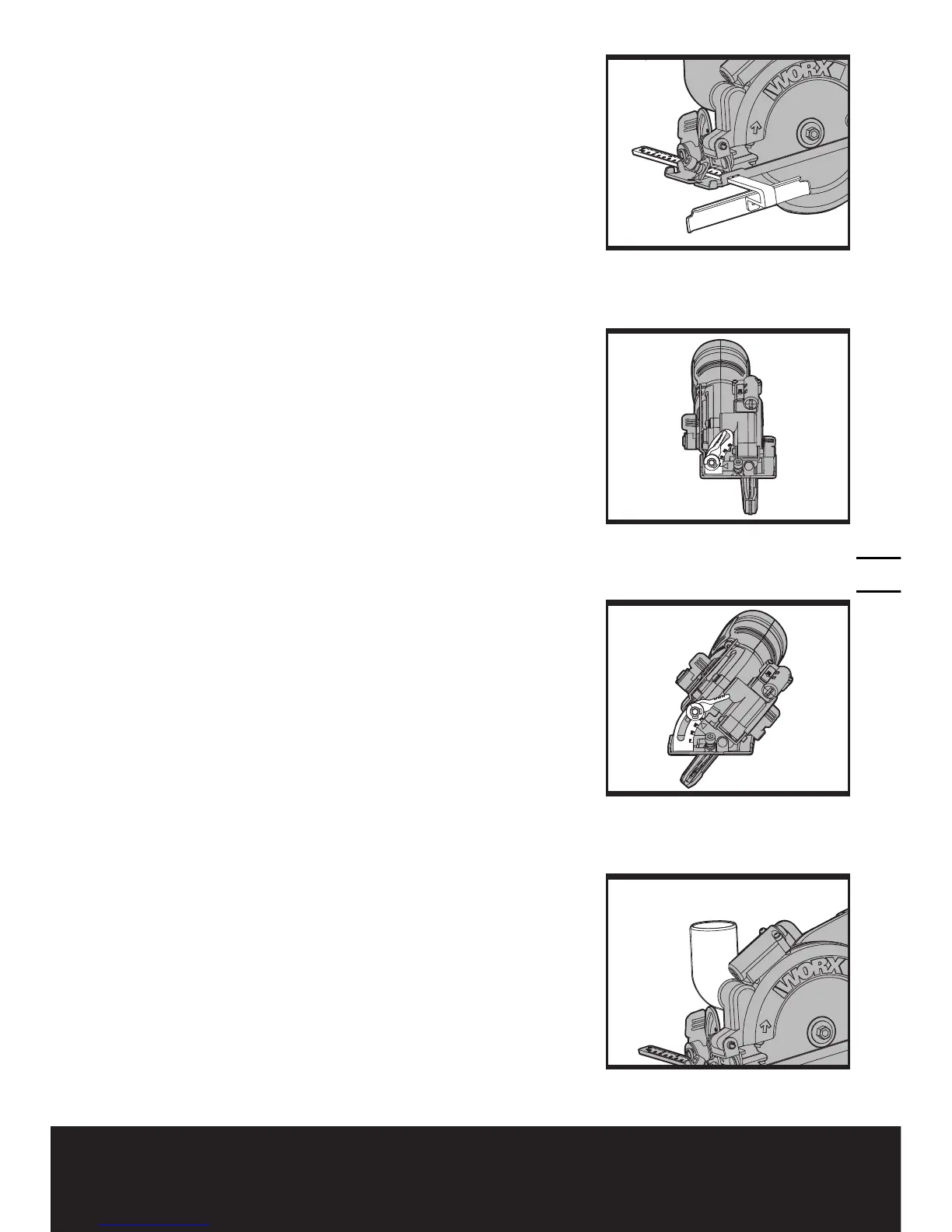

4. PARALLEL GUIDE (See Fig. B)

The parallel guide is used for making long, straight rip

cuts.

Slide the parallel guide (16) through the parallel guide

clamping fixture (17) to the desired cutting distance and

tighten the clamping screw to lock into position. Do not

over tighten. It can be used from either side of the base

plate (12).

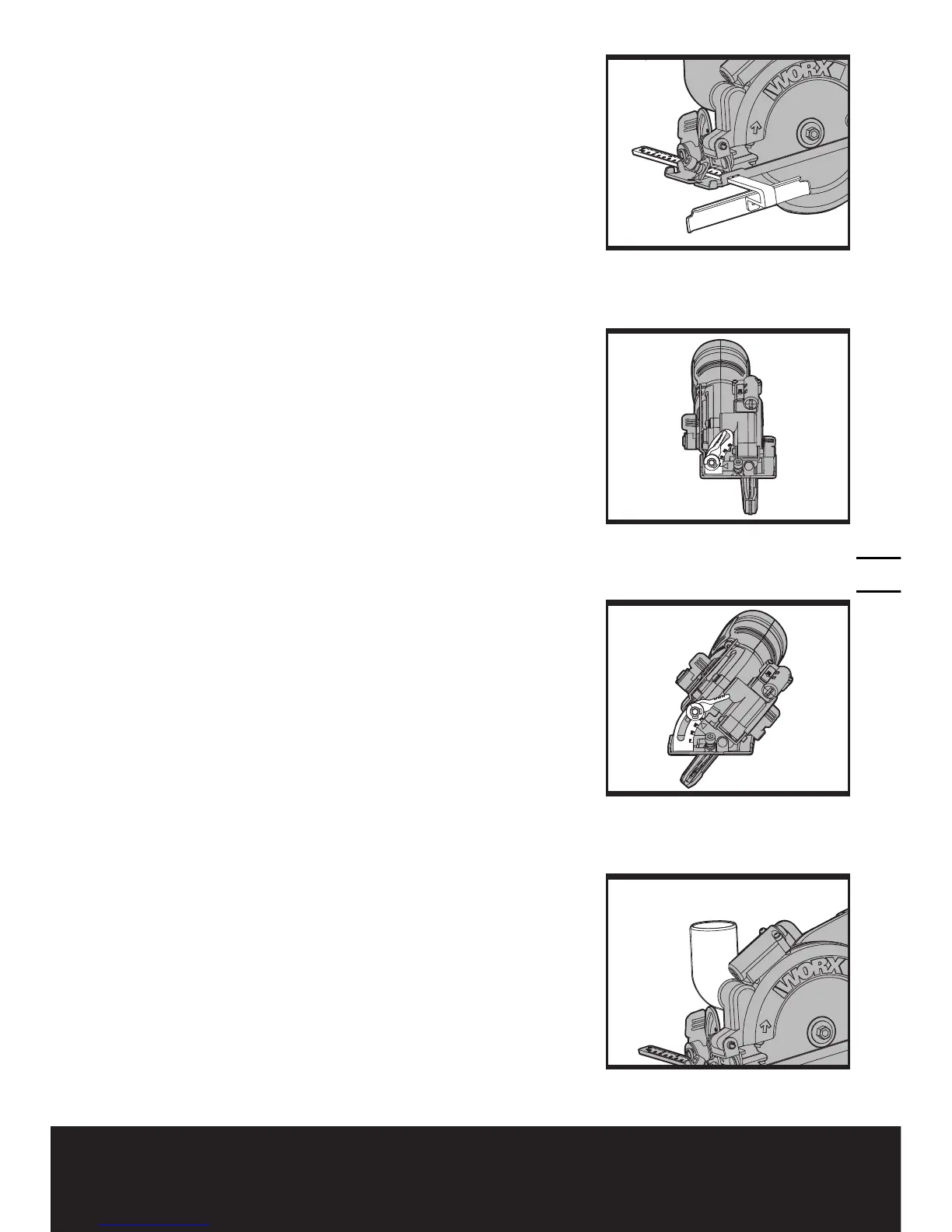

5. ADJUSTING THE CUTTING ANGLE

(See Fig. C1, C2)

Release the Bevel Adjustment Lever (18) by pushing it

in the counter-clockwise direction.

-Manually tilt the base plate (12) up or down to the

desired depth on the scale.

-Secure the Bevel Adjustment Lever (18) by pushing

it back down (clockwise) to lock the base plate at the

desired depth.

NOTE: The location of the blade cut-line will change

depending on the bevel angle that is being used. The

blade cut-line location when cutting at 90 degrees or 45

degrees is marked with a notch on the front of the base

plate (12).

The base plate (12) must always be held firmly against

the material being cut to reduce saw vibration, blade

jumping, or blade breakage.

6. SAWDUST REMOVAL (See Fig. D)

Your saw includes a vacuum adapter (10) that attaches

to the dust extraction outlet (9) on the saw. This

adapter port can be attached to a vacuum cleaner

(sold separately). The use of the vacuum is strongly

recommended as it keeps the work area clean,

dramatically increases cut visibility and reduces

Loading...

Loading...