ENGINE

WG972-E4, WSM

1-S43

Correcting Valve and Valve Seat

• Before correcting the valve and seat, check the valve stem

and the I.D. of valve guide section, and repair them if

necessary.

• After correcting the valve seat, be sure to check the valve

recessing.

1) Correcting Valve

1. Correct the valve with a valve refacer.

2) Correcting Valve Seat

1. Slightly correct the seat surface with a 0.785 rad (45 °) valve

seat cutter.

2. Resurface the seat surface with a 0.262 rad (15 °) valve seat

cutter.

3. After resurfacing the seat, lap the valve as follows.

9Y1211108ENS0068US0

Valve Lapping

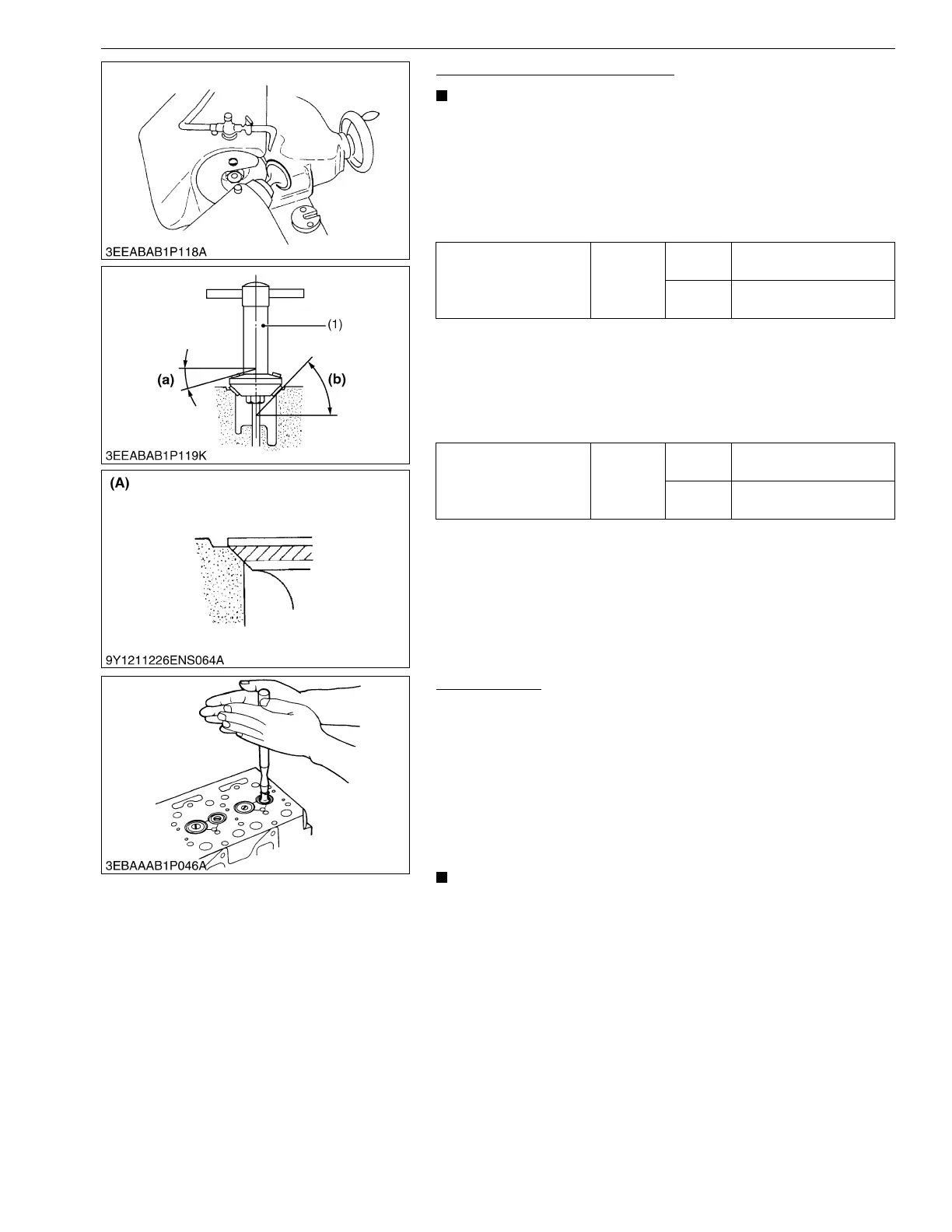

1. Apply compound evenly to the valve lapping surface.

2. Insert the valve into the valve guide. Lap the valve onto its seat

with a valve flapper.

3. After lapping the valve, wash the compound away and apply

prussian blue to the contact surface to check the seated rate.

4. If the valve seats all the way around the valve seat, apply oil and

repeat valve lapping with oil.

5. If the valve contact is incorrect, replace or correct the valve or

correct the contact of valve seating.

• When valve lapping is performed, be sure to check the

valve recessing and adjust the valve clearance after

assembling the valve.

9Y1211108ENS0069US0

Valve face angle

Factory

specifica-

tion

IN.

0.785 rad

45 °

EX.

0.785 rad

45 °

Valve seat angle

Factory

specifica-

tion

IN.

0.785 rad

45 °

EX.

0.785 rad

45 °

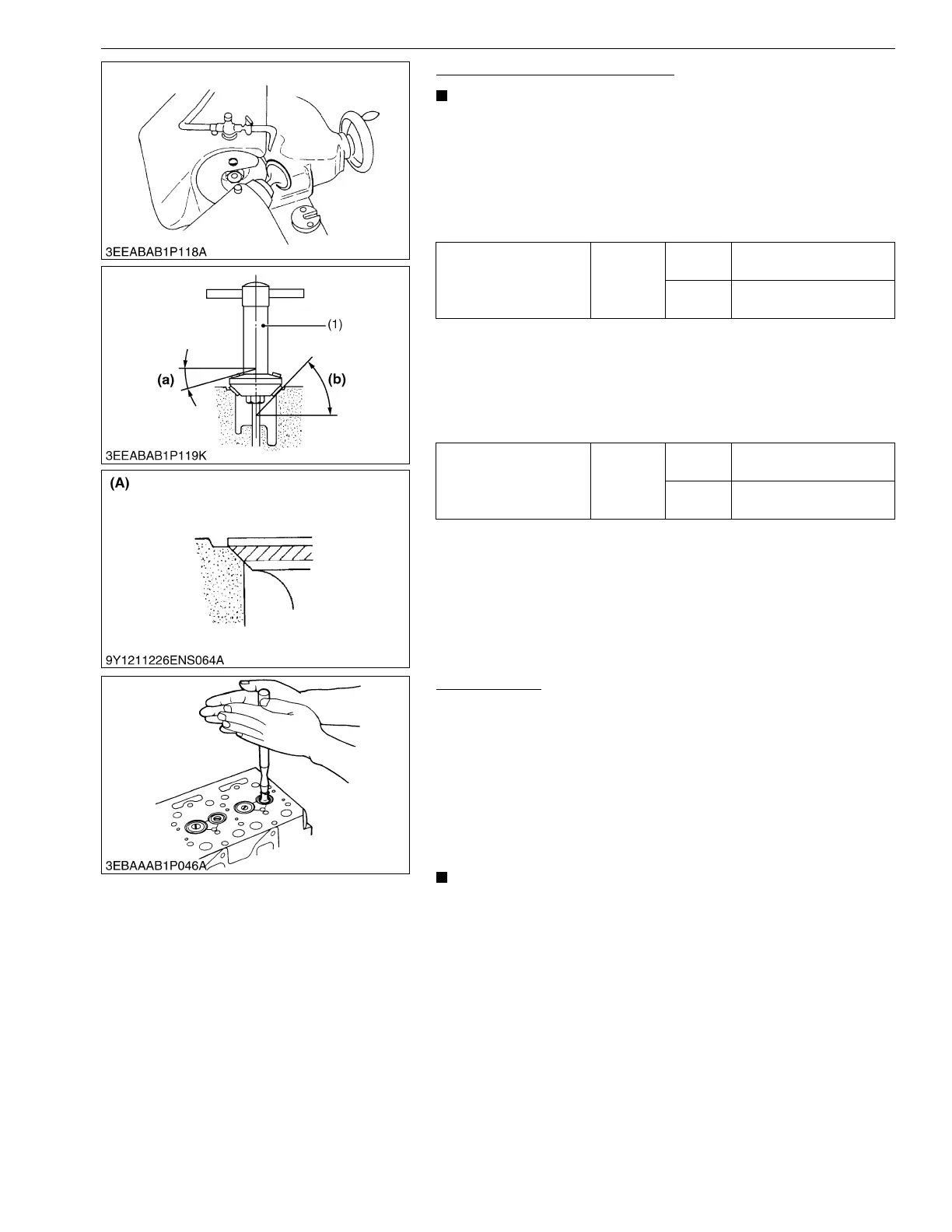

(1) Valve Seat Cutter

(A) Check Contact

(a) 0.262 rad (15 °)

(b) 0.785 rad (45 °)

Loading...

Loading...