Generally, it is the

problem of the encoder

itself, or the power

supply of the encoder is

unstable

(the driver panel shall be

completely off). If the alarm

cannot be removed, please

contact the agent or manufacturer

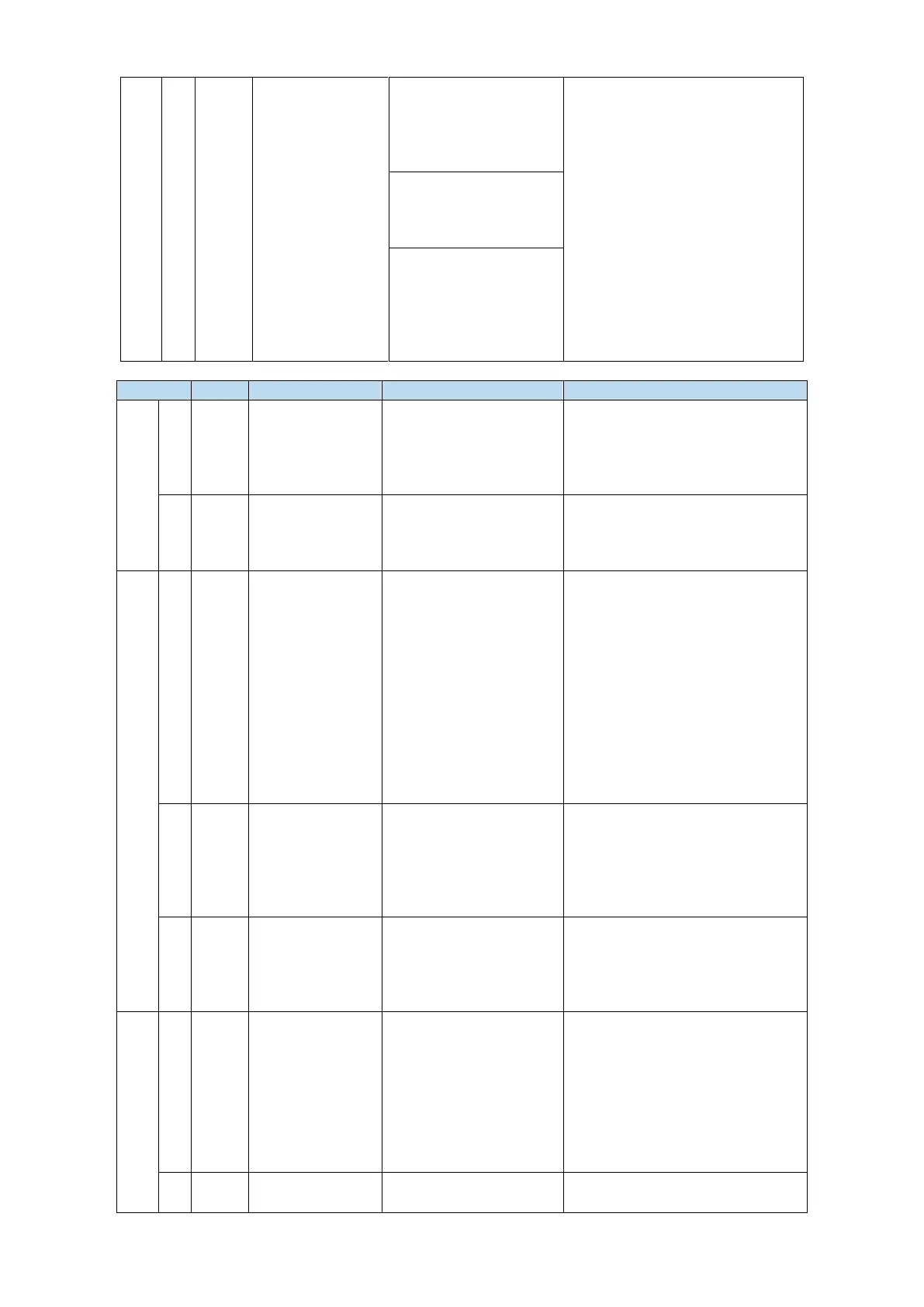

Abnormal power on of

main control chip of

multi-turn absolute

value servo encoder

ADC sampling is out of

range, some resistance

and capacitance devices

have problems or the

signal consistency of

magnetic sensor is poor

Power on

encoder multi

turn signal data

error

Generally, it is the

problem of the encoder

itself, or the power

supply of the encoder is

unstable

In the case of no battery,

unplugging the encoder cable may

cause this alarm.

Absolute value

servo encoder

value overflow

The motor runs in one

direction continuously,

the encoder data value is

too large, overflow

① Set F1-06 = 1, clear the

absolute encoder's multiple turns;

② Set P0-79 = 2, the alarm can

be shielded.

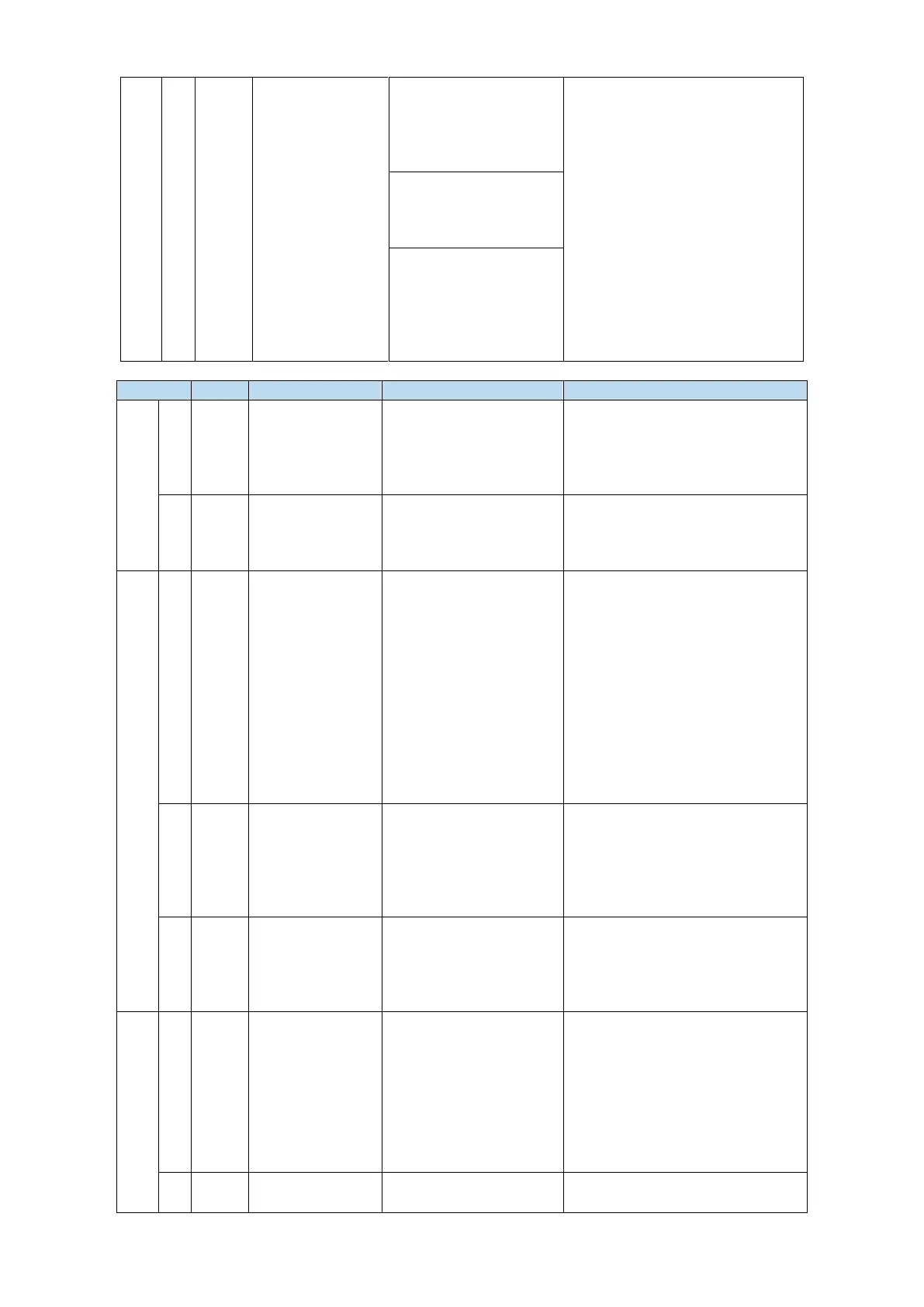

The error

between motor

encoder feedback

and displacement

sensor feedback

(user command

resolution)

exceeds the

setting value of

P9-02

The error between motor

encoder feedback and

grating encoder feedback

(user command

resolution) exceeds the

setting value of P9-02

① Mechanism error. The motor

outputs the shaft position directly

and reaches the moving platform

through the mechanism. The

feedback of the grating ruler is

directly from the moving

platform, and there will be errors

in it after passing through the

synchronous belt or lead screw

② Grating ruler installation is not

parallel

③ Set P9-05 to P9-08 reasonably

Fully closed-loop

motor encoder

and external

grating ruler

counter direction

reverse

When P9-02 is set to 0,

the grating ruler is

broken or not connected

correctly.

Check the grating ruler and power

on again

Full closed loop

external grating

scale speed

overrun

The error between the

feedback speed of motor

encoder and that of

grating ruler exceeds the

set value of P9-04.

Check that the correct P9-05 ~

P9-08 is selected for the

mechanism and power on again.

Timing error in

fetching encoder

position data

① The number of

consecutive errors in

encoder data update

sequence is greater than

the value in P0-68

② Check the arrangement of

transmission cables to ensure that

the strong and weak current are

wired separately.

③ High current equipment is

supplied separately.

④ The grounding is good.

The received encoder

data is wrong and the

① Check the arrangement of

transmission cables to ensure that

Loading...

Loading...