6.1 Torque values

All screws and nuts must be lubricated to achieve correct tightening torque. Screws that

are screwed into stainless steel must have the threads coated with suitable lubricants to

prevent seizing.

If there is a question regarding the tightening torques, then contact a sales or authorized

service representative.

Screws and nuts

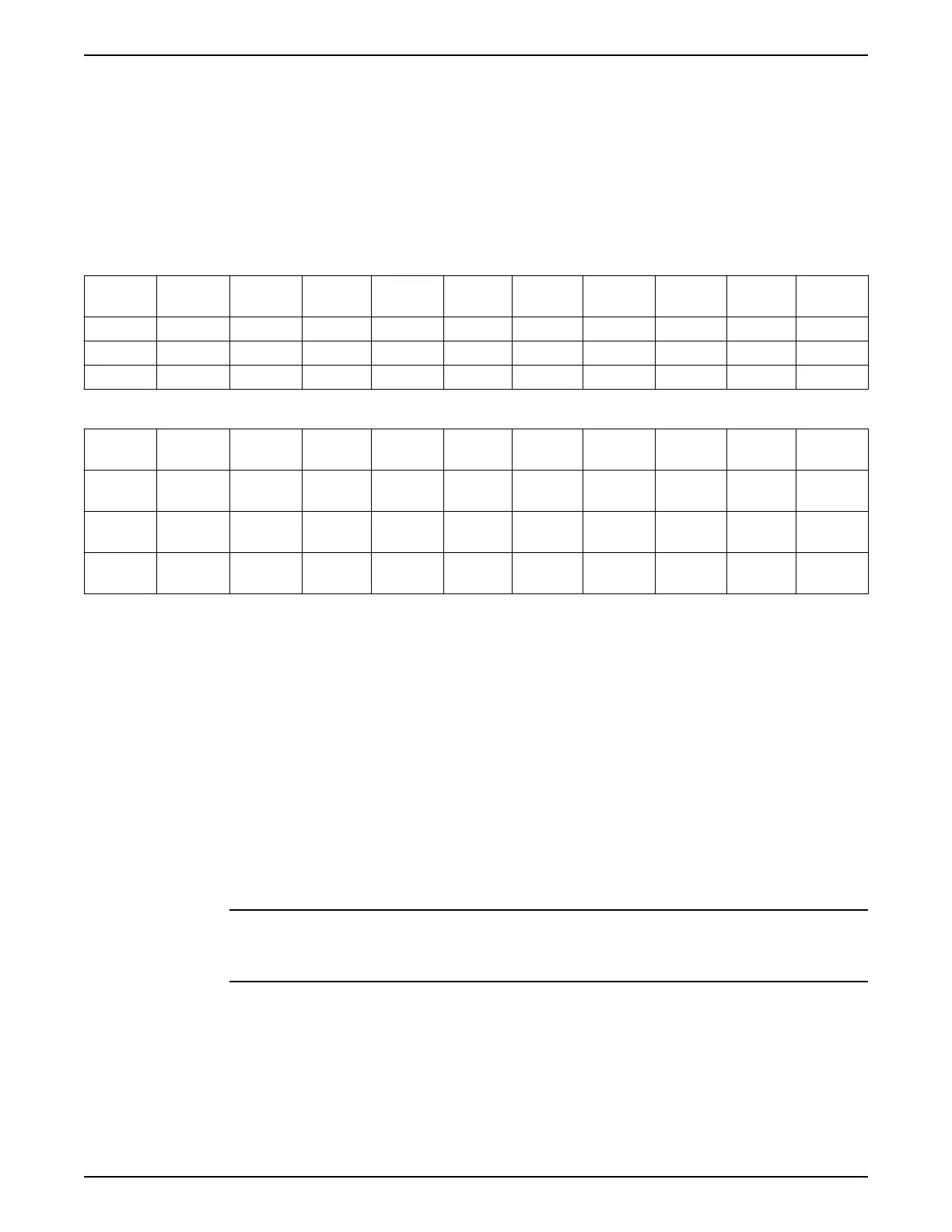

Table 1: Stainless steel, A2 and A4, torque Nm (ft-lbs)

Property

class

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

50 1.0 (0.74) 2.0 (1.5) 3.0 (2.2) 8.0 (5.9) 15 (11) 27 (20) 65 (48) 127 (93.7) 220 (162) 434 (320)

70, 80 2.7 (2) 5.4 (4) 9.0 (6.6) 22 (16) 44 (32) 76 (56) 187 (138) 364 (268) 629 (464) 1240 (915)

100 4.1 (3) 8.1 (6) 14 (10) 34 (25) 66 (49) 115 (84.8) 248 (183) 481 (355) — —

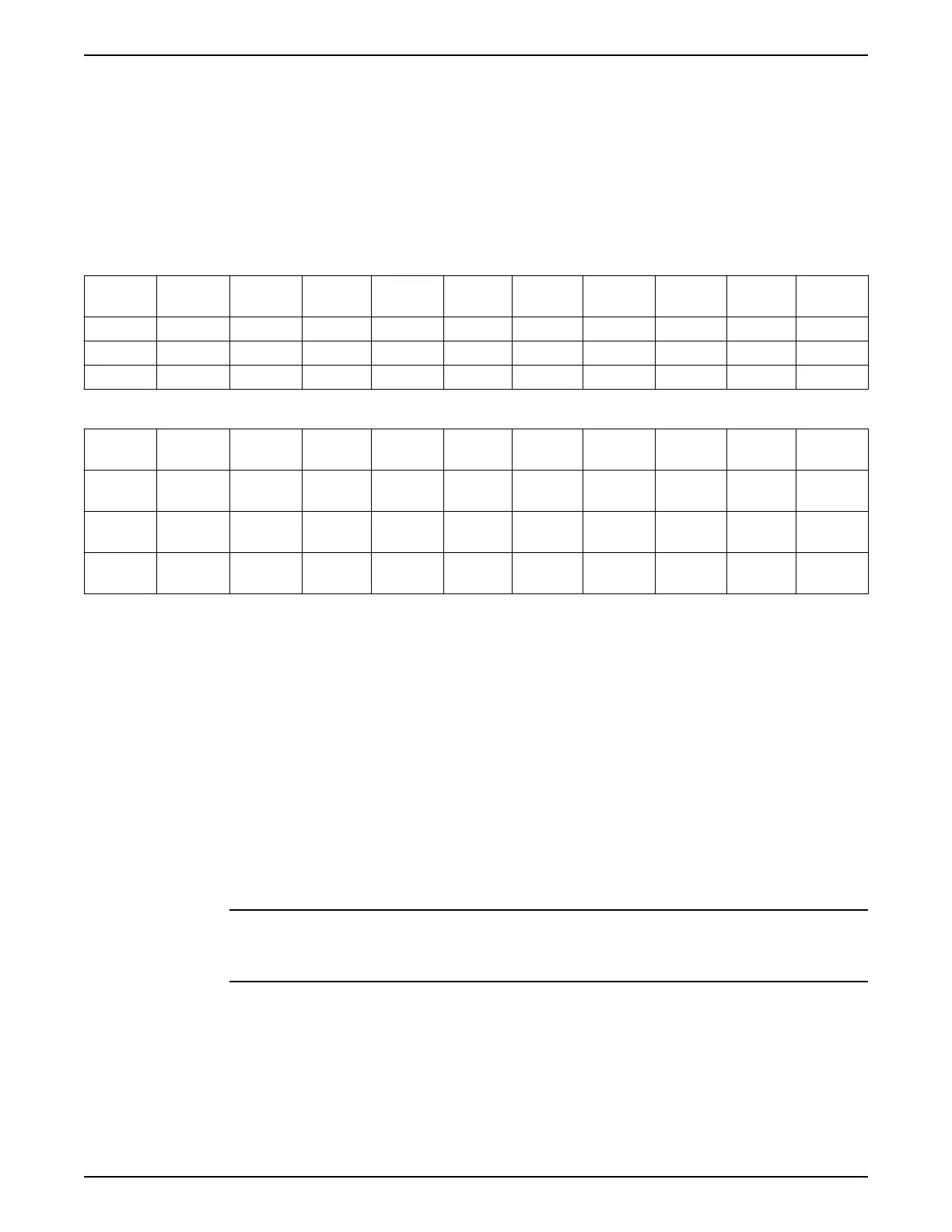

Table 2: Steel, torque Nm (ft-lbs)

Property

class

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

8.8 2.9 (2.1) 5.7 (4.2) 9.8 (7.2) 24 (18) 47 (35) 81(60) 194 (143) 385 (285) 665 (490) 1310

(966.2)

10.9 4.0 (2.9) 8.1 (6) 14 (10) 33 (24) 65 (48) 114 (84) 277 (204) 541 (399) 935 (689) 1840

(1357)

12.9 4.9 (3.6) 9.7 (7.2) 17 (13) 40 (30) 79 (58) 136 (100) 333 (245) 649 (480) 1120

(825.1)

2210

(1630)

Hexagon screws with countersunk heads

For hexagon socket head screws with countersunk head, maximum torque for all property

classes must be 80% of the values for property class 8.8 above.

6.2 Service

Regular service of the pump ensures more reliable operation.

Inspection

The pump should be inspected at least twice a year, more frequently under severe

operating conditions.

Screw tightening

During assembly or service of the pumps we recommend that the screws be tightened to

approximately 6–8 Nm (4.5–6 ft-lbs). The tightening torque ensures that the parts are

correctly fastened and that the pumps will operate as intended.

NOTICE:

Make sure that the oil-plug and securing screws for the strainer or the pump housing are

not tightened too hard.

To maintain screw tightness, use some mineral oil on all non-stainless steel screws.

When using stainless steel screws on stainless steel parts, apply Aral Degol GS 460 or

National Chemseal Thread-Eze lubricant in order to prevent the screws from seizing.

6.3 Change the oil

A paraffin oil with viscosity close to ISO VG32 is recommended. The pump is delivered

from the factory with this type of oil. Examples of suitable oil types are the following:

6 Maintenance

2008 Ready 8, 8S Installation, Operation, and Maintenance 21

Loading...

Loading...