Installation, Operating and Maintenance Instruction Model MPB, MPV

Be particularly careful not to touch hot machine

parts and when working in the unprotected shaft

seal area. Remember that automatically

co

ntrolled systems may switch themselves

nly at any time.

Suitable warning signs

should be affixed.

6.4 Limits of Operation

The operating limits of the pump / unit regarding

pressure, temperature, performance and speed

are shown in the data sheet and / or order

co

nfirmation and must

be observed under any

circumstances!

Do not exceed the output given on the motor

name plate.

Avoid sudden changes in temperature

(temperature shocks).

The pump and motor should run evenly and

without vibrations; check at least once a week.

6.4.1 Flow min. / max.

If no other data are given in the curves or data sheets,

the following is valid:

Q

min

= 0,1 x Q

BEP

for for short time operation

Q

min

= 0,3 x Q

BEP

for continuous operation

Q

max

= 1,2 x Q

BEP

for continuous operation *)

Q

BEP

= Flow in efficiency optimum

*) on condition that NPSH

facility

> (NPSH

pump

+ 0,5 m)

6.4.2 Abrasive Media

On pumping liquids with abrasive components

an increased wear at hydraulic and shaft se

a

ling

must be expected. The intervals of inspe

c

tion

should be reduced compared to

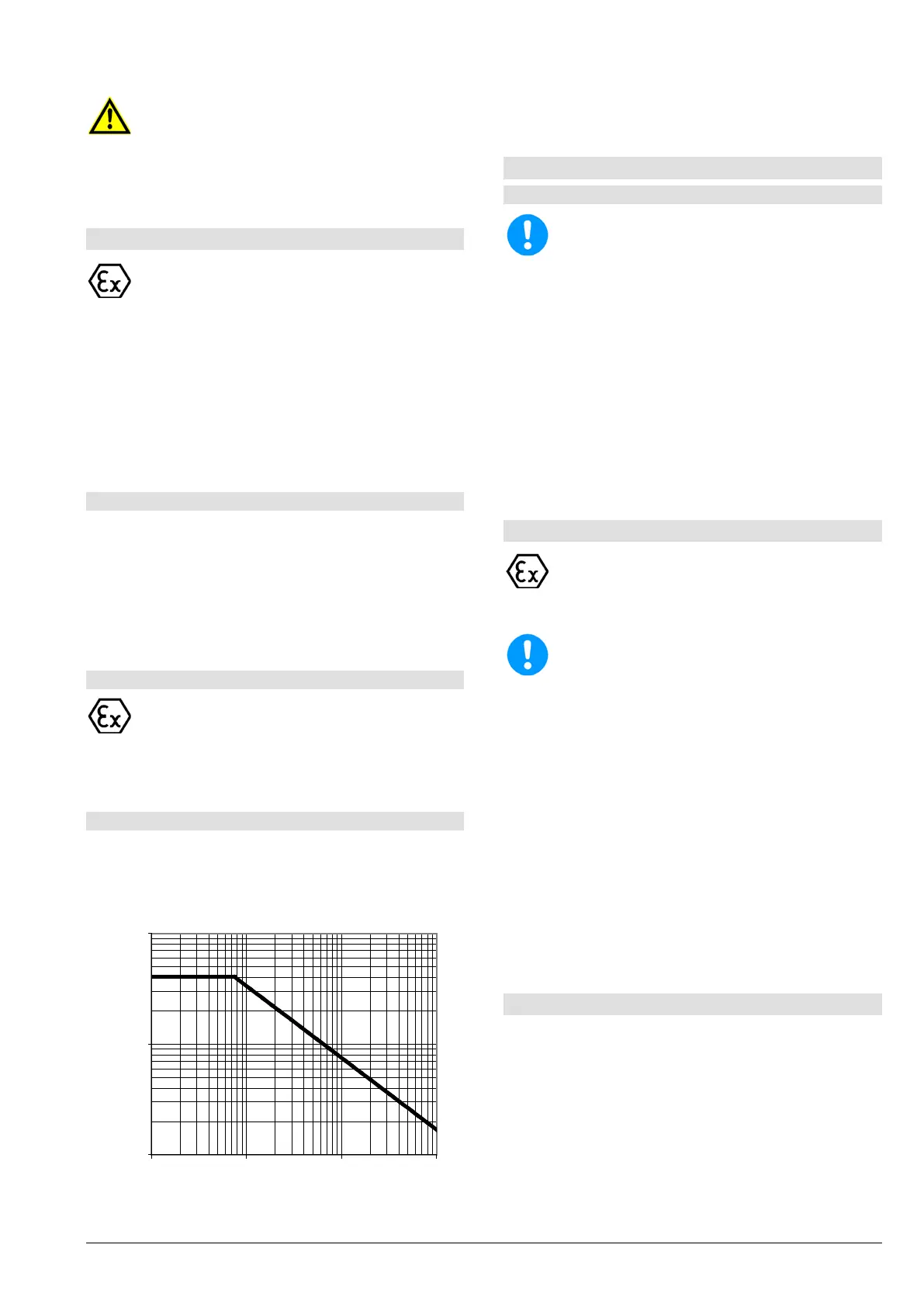

6.4.3 Permitted number of starts

With electric motors, the permitted number of starts is

given in the attached motor operating instructions.

If no values for the switching frequency are given in

the motor operating manual, the values according to

Diagram 7 apply.

3

1,0

10,0

100,0

1 10 100 1000

Diagram 7

If two different figures are given, the lower figure is

valid.

6.5 Lubrication of Bearings

Grease Lubrication – MPV Design Only

For quality of grease refer to chapter 7.4.

For

quantity of grease refer to chapter 7.4.

The bearings are already filled with lithium based

grease at the factory and are thus ready for use.

The grease provided is suitable for a temperature

range from -30° to +90°C (measured at surface of

bearing bracket).

Re-lubrication via the two grease nipples (G).

Bearing temperature (measured at bearing

bracket) should lie max. 50°C over ambient

temperature and must not exceed 90°C, control

weekly at least. On grease lubrication the bearing

temperature can temporarily be higher by 5-10°C

after regreasing, till a possible surplus of grease in

the bearings is cut.

6.6 Monitoring

In areas endangered to explosion it is

reco

m

mended to monitor the temperature of the

bea

r

ings and the vibrations of the bearing

bracket.

Regular monitoring and maintenance will extend

the life of your pump or pump system

.

Check pump for leaks at least once a week.

On packing, check quantity of leakage at least

once a week (see chapter 6.2 section "Packing").

Check the regulating and monitoring devices of

any sealing, flushing or cooling systems once a

week to ensure that they function properly.

Outgoing cooling water should be hand warm.

With double mechanical seals, monitor pressure

and flow rate in mechanical seal area; check at

least once a week.

Pumps which are exposed to corrosive chemicals

or to wear through abrasion must be inspected

periodically for corrosion or wear and tear. The

first inspection should be carried out after six

months. All further inspection intervals should be

determined on the basis of the state of the pump.

6.7 Shutting down

Close the valve in discharge pipe right before

(max. 10 seconds) switching off the motor. This is

not necessary if there is a spring-loaded check

valve.

Switch off motor (make sure it runs down quietly).

Close the valve on suction side.

Close auxiliary systems. Do not shut down cooling

system until pump has cooled down.

If there is any risk of freezing, empty pump,

cooling areas and pipes completely.

MPB 100-english page 81

Article No 771074115

Loading...

Loading...