OIL PUMP

5-45

TIP

When installing the inner rotor, align the pin “4”

in the oil pump shaft with the groove in the inner

rotor “5”.

3. Check:

●

Oil pump operation

Refer to “CHECKING THE OIL PUMP” on

page 5-43.

EAS25030

INSTALLING THE OIL PUMP

1. Install:

●

Oil pump drive chain

●

Oil pump

●

Oil pump bolts

●

Dowel pins

●

Oil delivery pipe

NOTICE

ECA4S81018

After tightening the bolts, make sure the oil

pump turns smoothly.

EAS25040

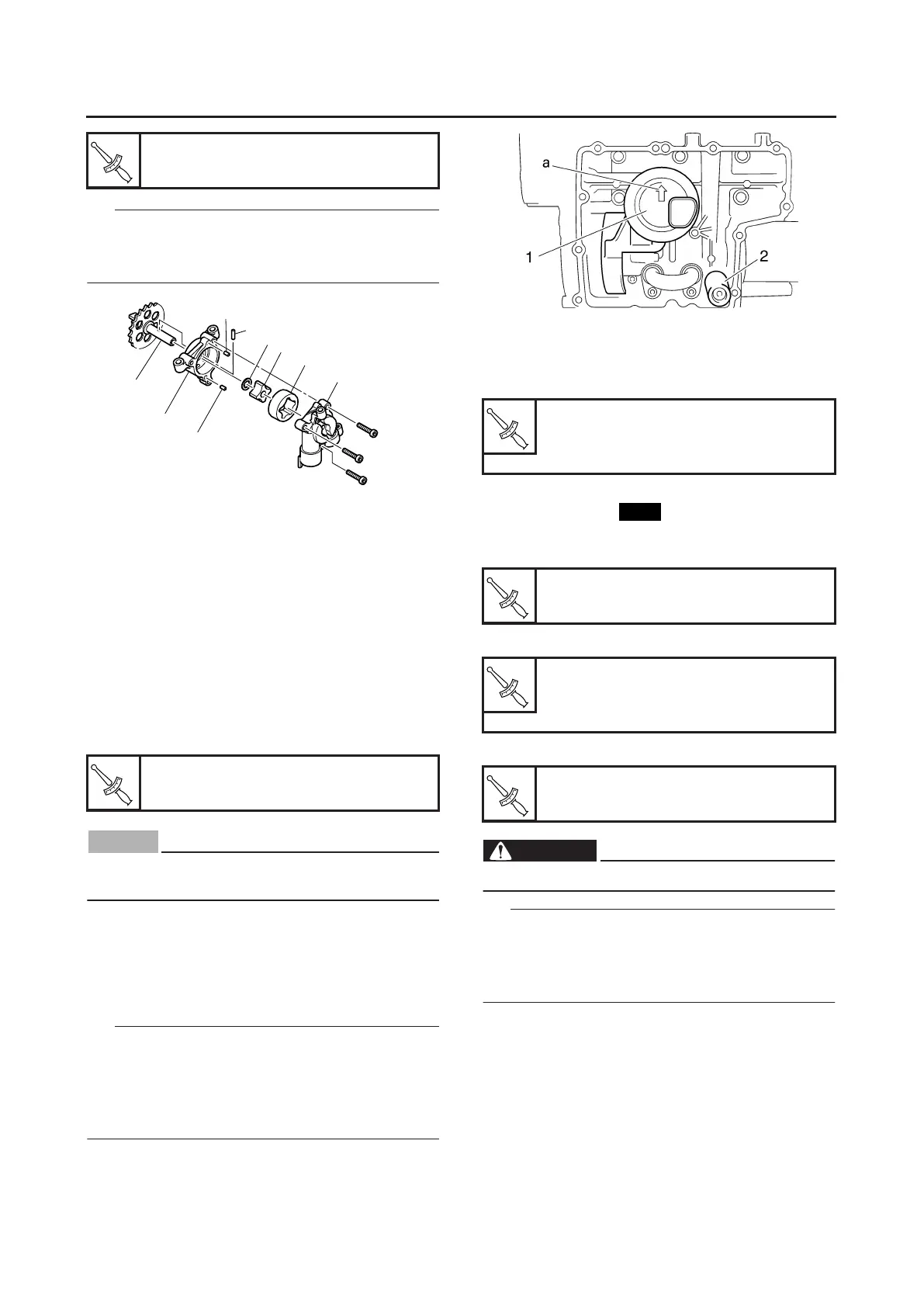

INSTALLING THE OIL STRAINER

1. Install:

●

Oil strainer “1”

●

Relief valve “2”

TIP

Make sure to check the arrow mark “a” located

on the oil strainer housing for the front and rear

direction of the engine and then install the oil

strainer so that its arrow mark points to the front

side of the engine.

EAS25050

INSTALLING THE OIL PAN

1. Install:

●

Oil pipe

2. Install:

●

Oil pan gasket

●

Oil pan “1”

●

Oil level switch lead holder

●

Oil level switch “2”

●

Engine oil drain bolt

WARNING

EWA12820

Always use new copper washers.

TIP

●

Tighten the oil pan bolts in stages and in a

crisscross pattern.

●

Lubricate the oil level switch O-ring with lithi-

um-soap-based grease.

Oil pump housing screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pump bolt

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

T

R

.

.

1

2

3

4

5

6

7

8

7

T

R

.

.

Oil pipe bolt

12 Nm (1.2 m·kgf, 7.2 ft·lbf)

LOCTITE®

Oil pan bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil level switch bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Engine oil drain bolt

43 Nm (4.3 m·kgf, 31 ft·lbf)

T

R

.

.

New

T

R

.

.

T

R

.

.

T

R

.

.

❄❉❂❋❇ ✧

Loading...

Loading...