2. Inspection and Adjustment

33

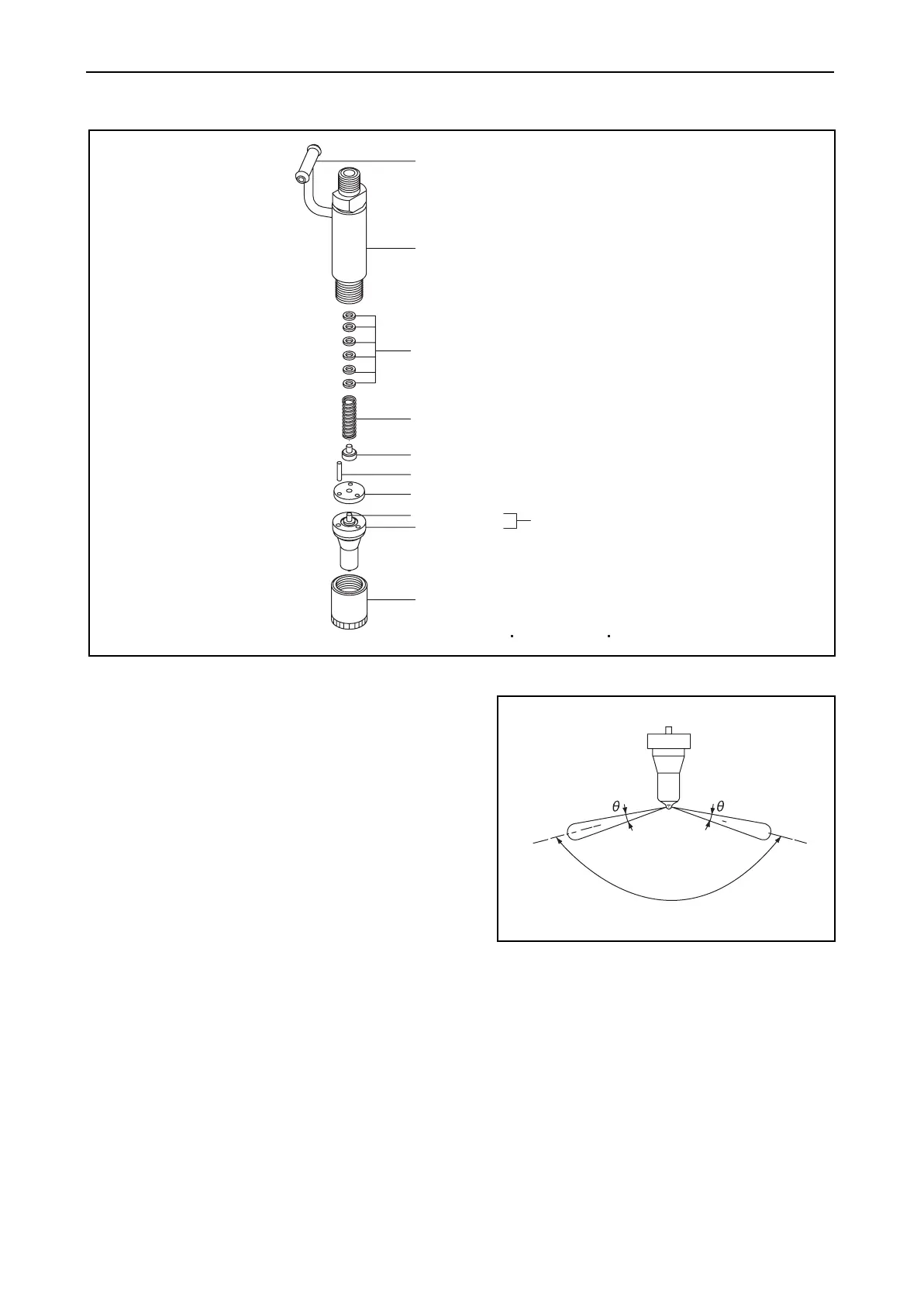

[Informative: Fuel injection valve structure]

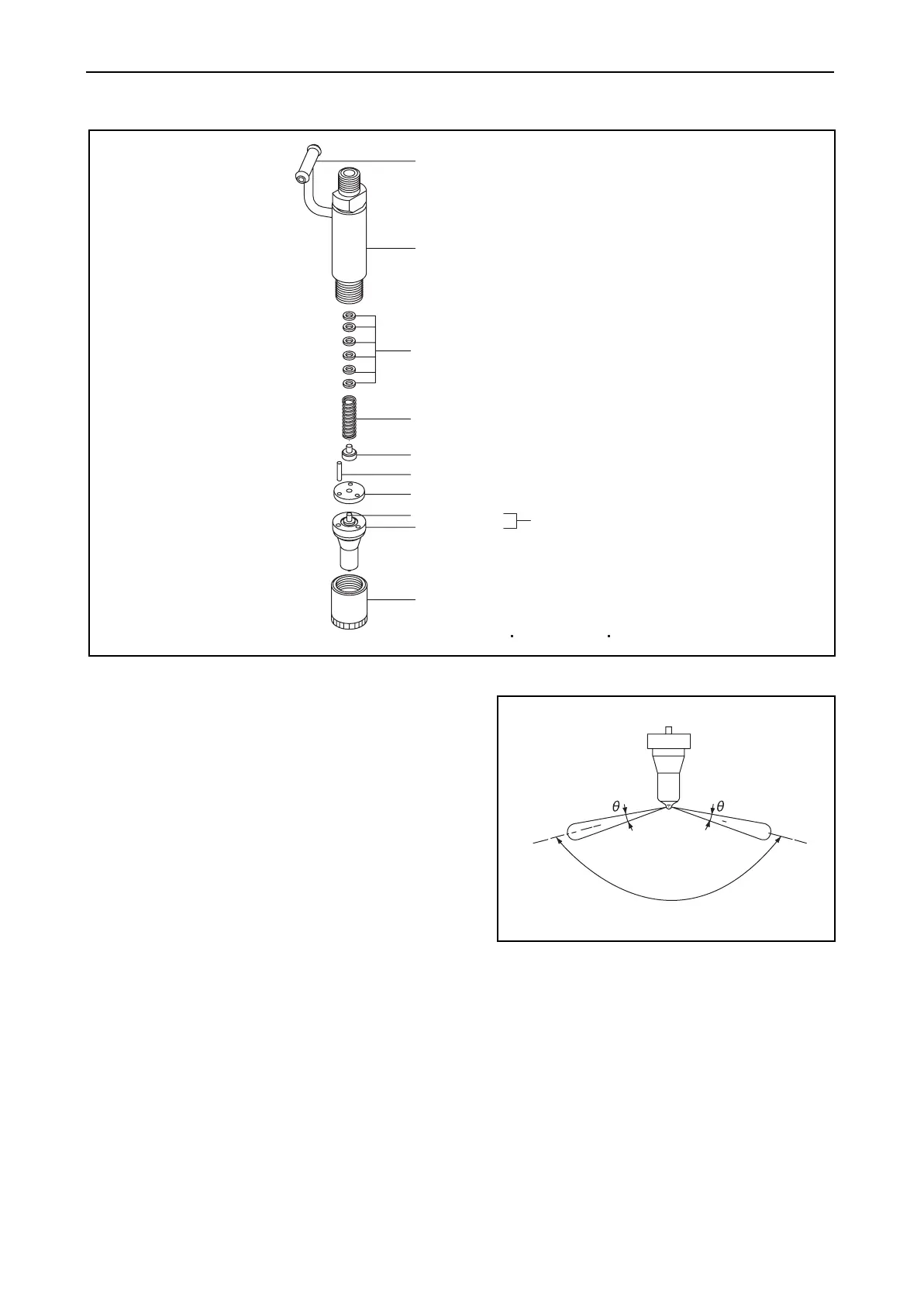

2) Spray pattern inspection

After adjustment to the specified valve opening

pressure, use a nozzle tester and check the spray

pattern and seat oil-tightness.

a) Seat oil tightness check

• After injecting a few times, increase the pressure

gradually. Hold the pressure for about 5 seconds

at a little before the valve opening pressure of

1.96 MPa (20kgf/cm

2

), and check to see that oil

does not drip from the tip end of the nozzle.

• If extreme oil leak from the overflow joint exists

during injection by the nozzle tester, check after

retightening. If much oil is leaking, replace the

nozzle assembly.

Nozzle holder

Pressure adjusting shim

Nozzle spring

Nozzle spring seat

F.O. return pipe joint

Valve stop spacer

Nozzle valve

Pin

Nozzle

Nozzle body

Nozzle case nut

Tightening torque:

39.2 to 44.1 N m (4 to 4.5 kgf m)

Normal

(Uniform spray pattern from each nozzle)

Loading...

Loading...