Chapter

2

Basic Engine

6. Connecting Rod

t4LHA Series

6-2

Crank

pin

bushing

6-2.1

Checking

crank pin bushing

Check

for flaking, melting or seizure on the contact

surface.

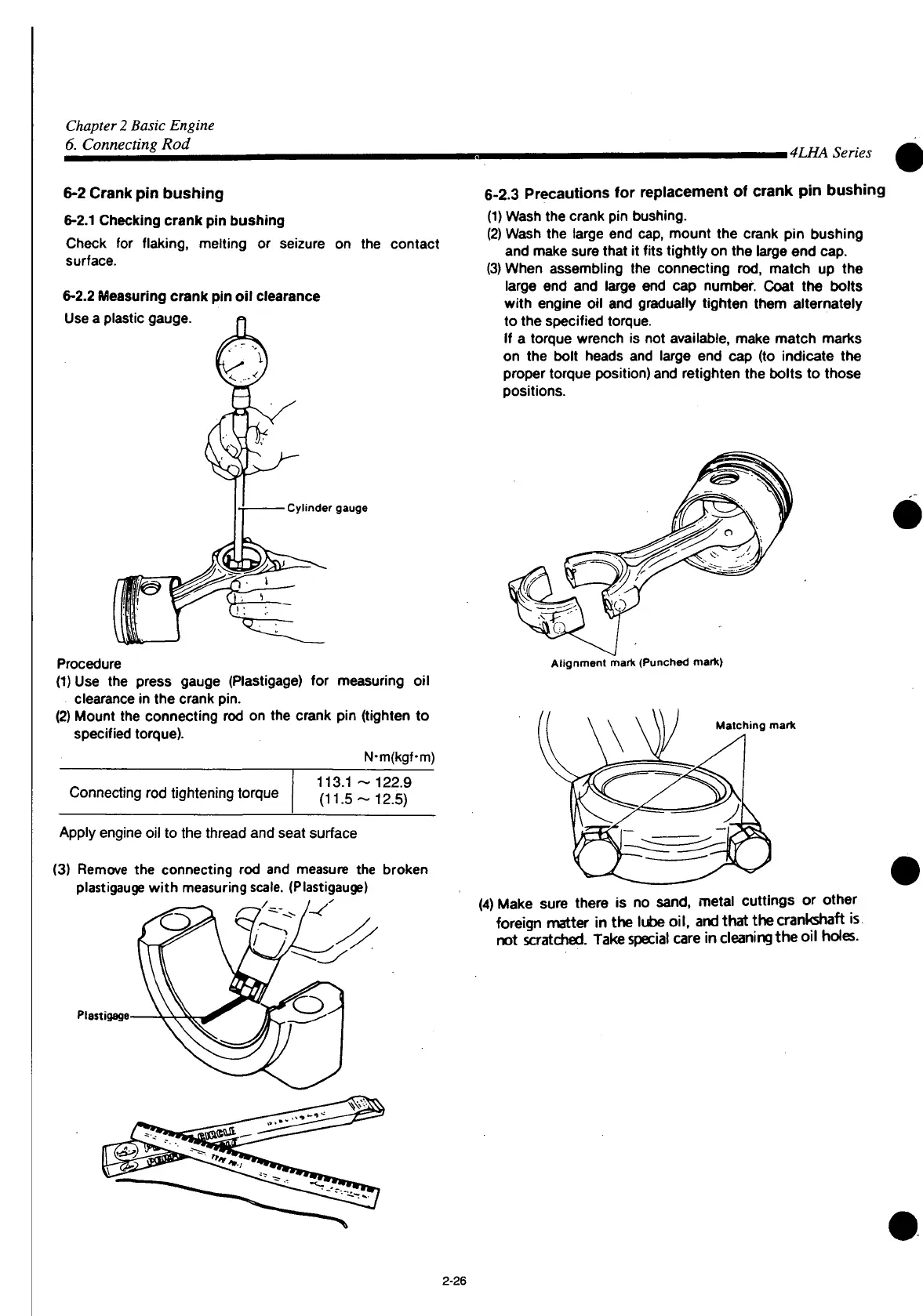

6-2.2 Measuring crank pin oil clearance

Use

a plastic gauge.

Cylinder

gauge

Procedure

(1) Use the press gauge (Plastigage) for measuring oil

clearance

in the crank pin.

(2) Mount the connecting rod on the crank pin

(tighten

to

specified

torque).

N'm(kgf-m)

Connecting

rod tightening torque

113.1 ~ 122.9

(11.5-12.5)

Apply

engine oil to the thread and seat surface

(3) Remove the connecting rod and measure the broken

plastigauge

with

measuring

scale.

(Plastigauge)

6-2.3 Precautions for replacement of crank pin bushing

(1) Wash the crank pin bushing.

(2) Wash the large end cap, mount the crank pin bushing

and

make sure

that

it

fits

tightly

on the large end cap.

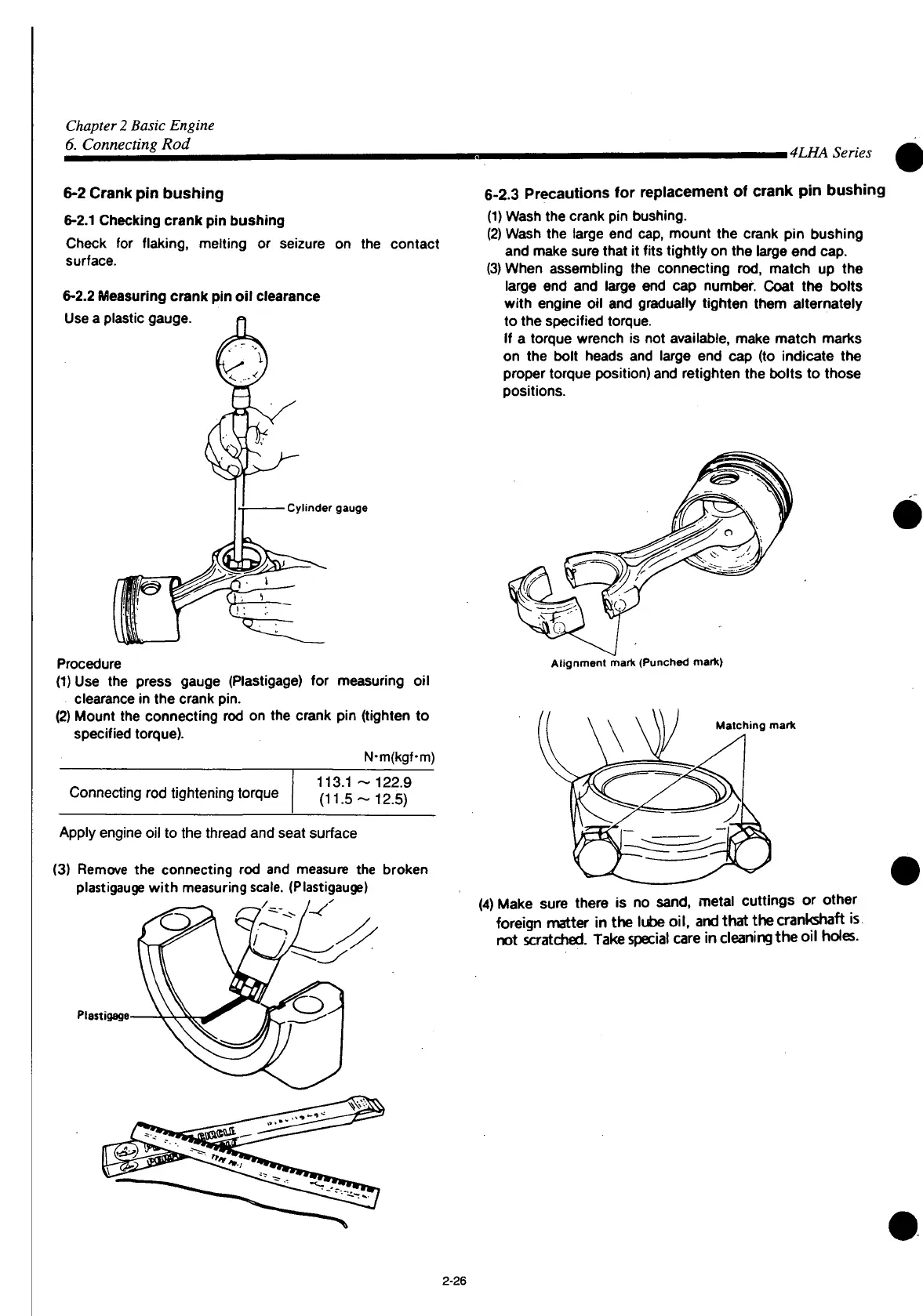

(3) When assembling the connecting rod, match up the

large end and large end cap number. Coat the bolts

with

engine oil and gradually

tighten

them alternately

to the specified torque.

If a torque wrench is not available, make match marks

on the

bolt

heads and large end cap (to indicate the

proper torque position) and retighten the bolts to those

positions.

Alignment mark (Punched mark)

Matching

mark

Plastigage

(4) Make sure there is no

sand,

metal cuttings or other

foreign matter in the lube oil. and

that

the crankshaft is

not scratched. Take

special

care in

cleaning

the oil holes.

2-26

Loading...

Loading...