Chapter 2 Basic Engine

3. Service Standards

t

4LHA Serie:

3.

Service

Standards

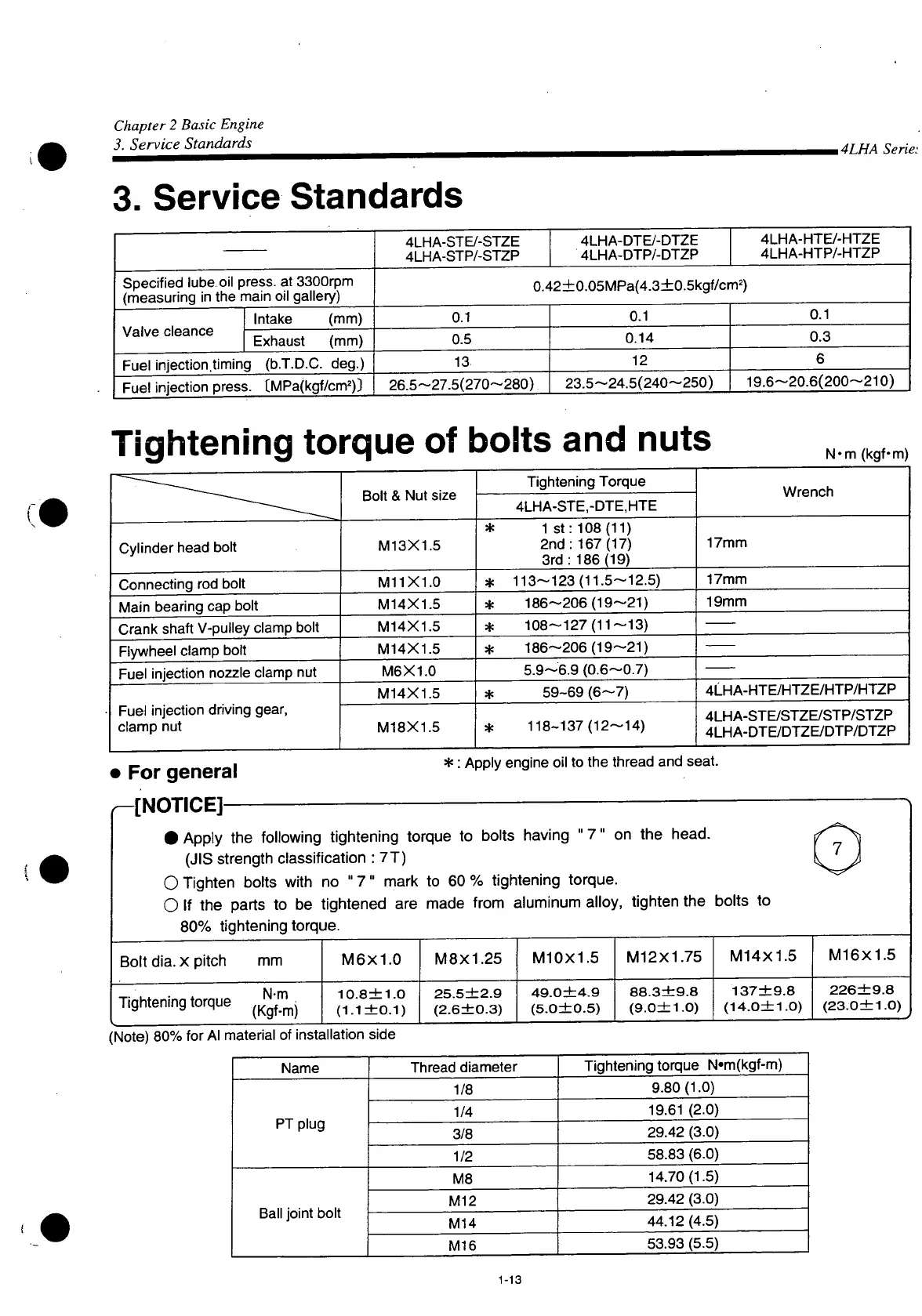

4LHA-STE/-STZE

4LHA-STP/-STZP

4LHA-DTE/-DTZE

4LHA-DTP/-DTZP

4LHA-HTE/-HTZE

4LHA-HTP/-HTZP

Specified

lube oil press,

at

3300rpm

(measuring

in the

main oil gallery)

0.42±0.05MPa(4.3±0.5kgf/cm

2

)

Valve

cleance

Intake

(mm)

0.1

0.1

0.1

Valve

cleance

Exhaust

(mm)

0.5

0.14

0.3

Fuel

iniection

timin

g (b.T.D.C.

deg.)

13

12

6

Fuel

injection press. (MPa(kgf/cm

2

)]

26.5-27.5(270-280)

23.5-24.5(240-250)

19.6-20.6(200-210)

Tightening

torque

of

bolts

and

nuts

N*m

(kgf-m)

Bolt

&

Nut

size

Tightening Torque

Wrench

Bolt

&

Nut

size

4LHA-STE,-DTE,HTE

Wrench

Cylinder

head bolt

M13X1.5

*

1st:

108(11)

2nd:

167(17)

3rd:

186(19)

17mm

Connecting

rod bolt

M11X1.0

* 113-123(11.5-12.5)

17mm

Main

bearing cap bolt

M14X1.5

* 186-206(19-21)

19mm

Crank

shaft V-pulley clamp bolt

M14X1.5

* 108-127(11-13)

Flywheel

clamp bolt

M14X1.5

* 186-206(19—21)

Fuel

injection nozzle clamp

nut

M6X1.0

5.9-6.9 (0.6-0.7)

Fuel

injection driving gear,

clamp

nut

M14X1.5

* 59-69

(6-7)

4LHA-HTE/HTZE/HTP/HTZP

Fuel

injection driving gear,

clamp

nut

M18X1.5

* 118-137(12-14)

4LHA-STE/STZE/STP/STZP

4LHA-DTE/DTZE/DTP/DTZP

• For general

*

:

Apply engine oil

to

the thread and seat.

I'—[NOTICE]

• Apply

the

following tightening torque

to

bolts having

"7" on the

head.

(JIS strength classification

: 7T)

OTighten bolts

with

no "7"

mark

to 60%

tightening torque.

O

If the

parts

to be

tightened

are

made from aluminum alloy, tighten

the

bolts

to

80%

tightening torque.

0

Bolt dia.

x

pitch

mm

M6X1.0

M8X1.25

M10X1.5

M12X1.75

M14X1.5

M16X1.5

Tightening torque

(K

N

g{

m

m)

10.8+1.0

(1.1±0.1)

25.5±2.9

(2.6±0.3)

49.0±4.9

(5.0±0.5)

88.3±9.8

(9.0±1.0)

137±9.8

(14.0±1.0)

226±9.8

(23.0±1.0)

(Note) 80%

for

Al material

of

installation side

Name

Thread

diameter

Tightening torque N»m(kgf-m)

PT

plug

1/8

9.80(1.0)

PT

plug

1/4

19.61

(2.0)

PT

plug

3/8

29.42

(3.0)

PT

plug

1/2

58.83

(6.0)

Ball

joint

bolt

M8

14.70(1.5)

Ball

joint

bolt

M12

29.42

(3.0)

Ball

joint

bolt

M14

44.12 (4.5)

Ball

joint

bolt

M16

53.93

(5.5)

1-13

Loading...

Loading...