Chapter 3 Fuel Injection Equipment

2. Bleeding and Checking Injection Timing

4LHA Serie

2. Check the

fuel

injection

timing

as

follows:

(1) Remove the high pressure pipe from the fuel injection

pump.

3.

Removal

and

installation

of

injection

pump

(1)

Remove

the fuel injection pump gear cover from the tim-

ing gear

housing

cover.

(2)

Make

mating marks on the idle gear and the injection

pump gear using white paint for reinstallation.

(3) Remove the pump drive shaft end nut, the washer,

the pump gear from the shaft, three pump retaining

bolts,

and two pump support bolts.

Remove

the injection pump.

NOTE: When removing the pump;

1) Do not drop keys from the drive shaft into the gear

housing.

2) Avoid damage to O-rings on the pump.

3) Do not hit the shaft end with a hammer.

(2)

Pull

the engine warm up knob out and place the control

lever

in the "half

speed"

position.

(3)

Insert

a turning bar

into

the hole on the crank

pulley on the

front

side.

Crank the engine lightly

to check the fuel injection timing.

(4) When installing the

pump,

match the mating marks on the

bracket and the pump flange.

(5) While aligning the mating marks on the idle gear and

the pump gear, install the pump to the pump gear.

(6) Tighten the drive shaft end nut to 69N-m(7kgf-m).

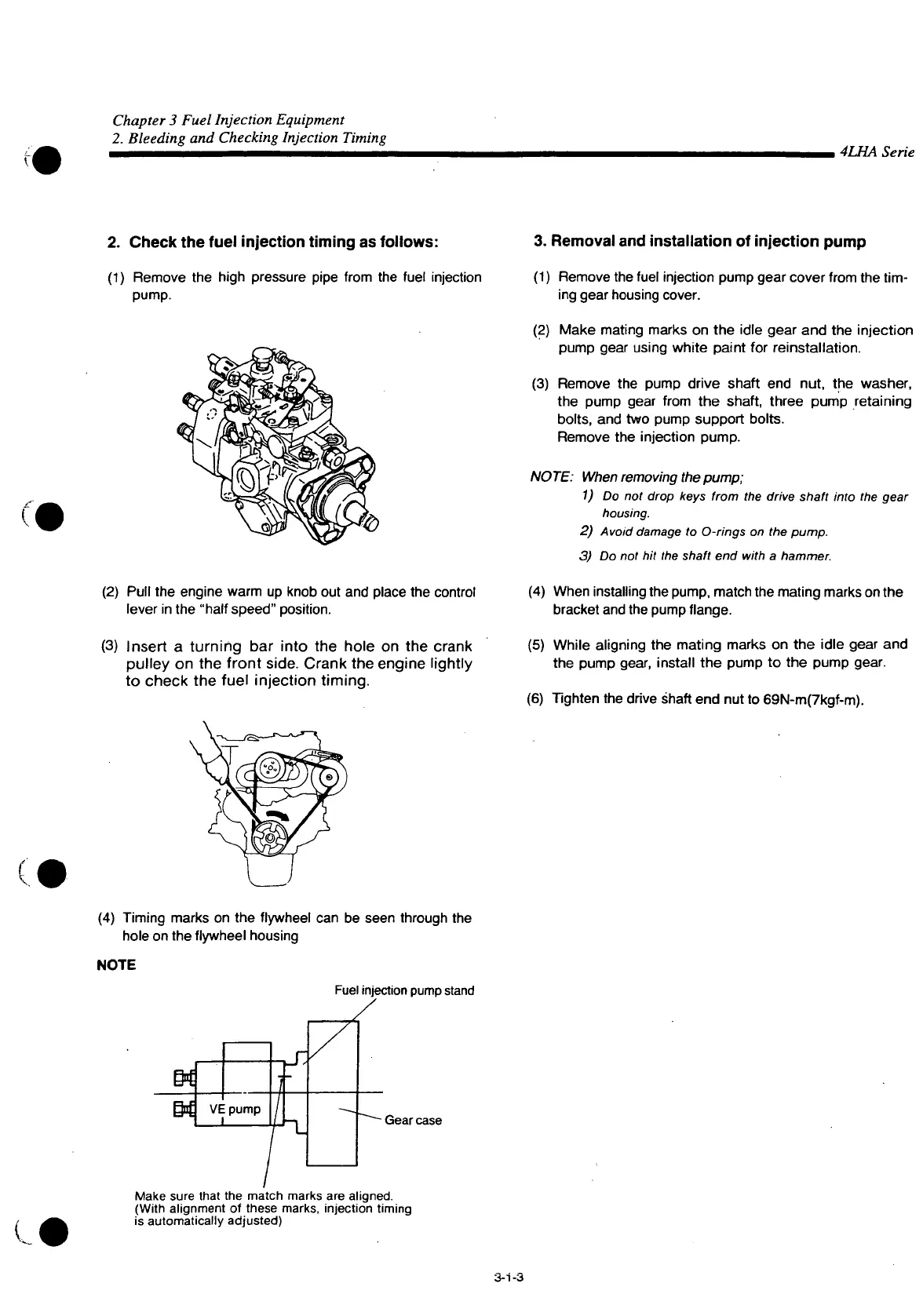

(4) Timing marks on the flywheel can be

seen

through the

hole

on the flywheel housing

NOTE

Fuel

injection pump stand

EM

VE

pump

I

-

Gear

case

Make

sure

that

the match marks are aligned.

(With alignment of these marks, injection timing

is

automatically adjusted)

3-i-3

Loading...

Loading...