Chapter 3 Fuel Injection Equipment

3. Disassembly, Reassembly and Inspection of Fuel Injection Pump

41HA Series

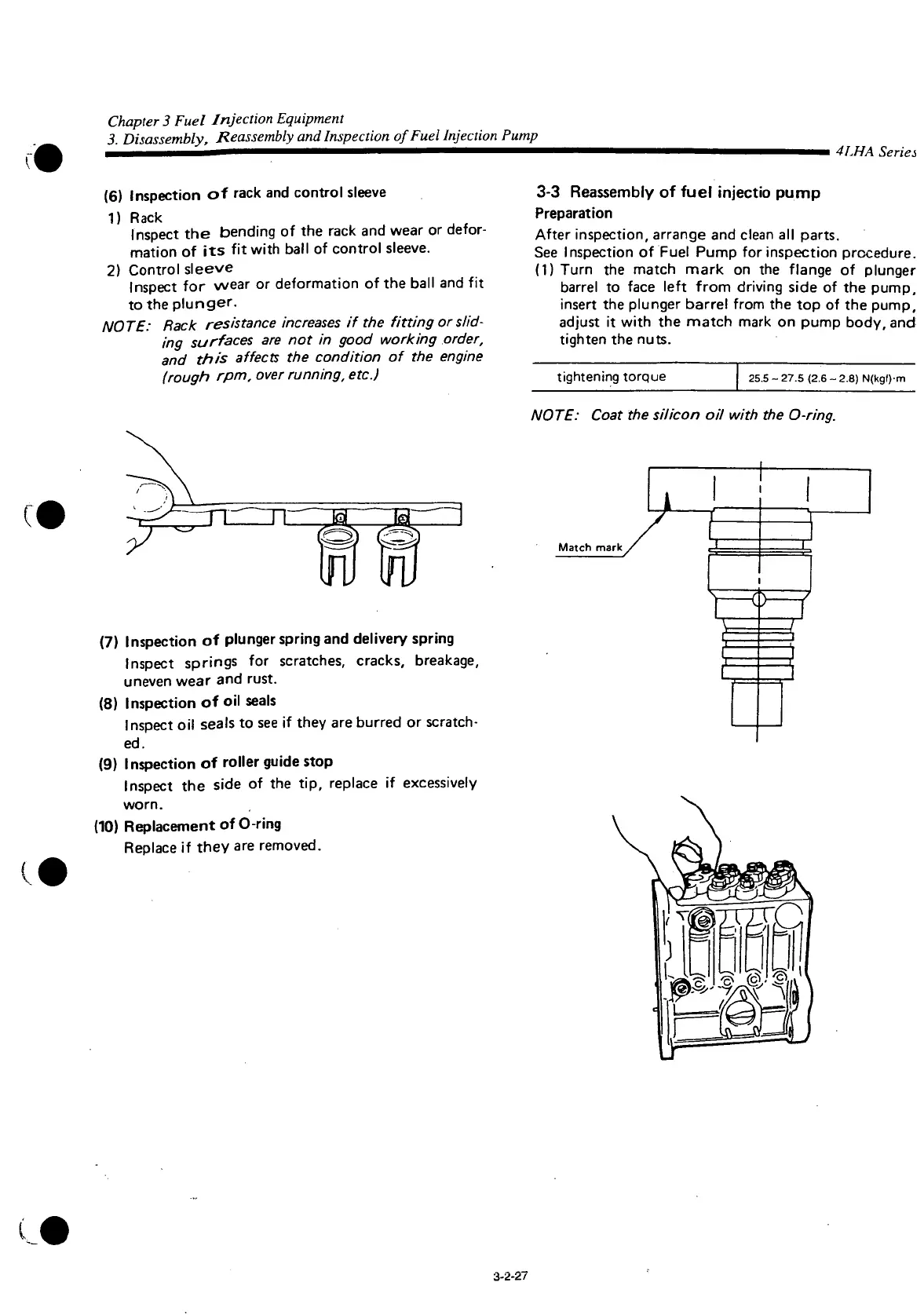

(6) Inspection of rack and control sleeve

1)

Rack

Inspect the bending of the rack and wear or defor-

mation of its fit

with

ball of control

sleeve.

2) Control sleeve

Inspect for wear or deformation of the ball and fit

to the plunger.

NOTE: Rack resistance increases if the fitting or slid-

ing surfaces are not in good working order,

and this affects the condition of the engine

(rough rpm, over running, etc.)

(7) Inspection of plunger spring and delivery spring

Inspect springs for scratches,

cracks,

breakage,

uneven

wear and rust.

(8) Inspection of oil

seals

Inspect oil

seals

to see if they are burred or scratch-

ed.

(9) Inspection of roller guide stop

Inspect the side of the tip, replace if excessively

worn.

(10) Replacement of O-ring

Replace

if they are removed.

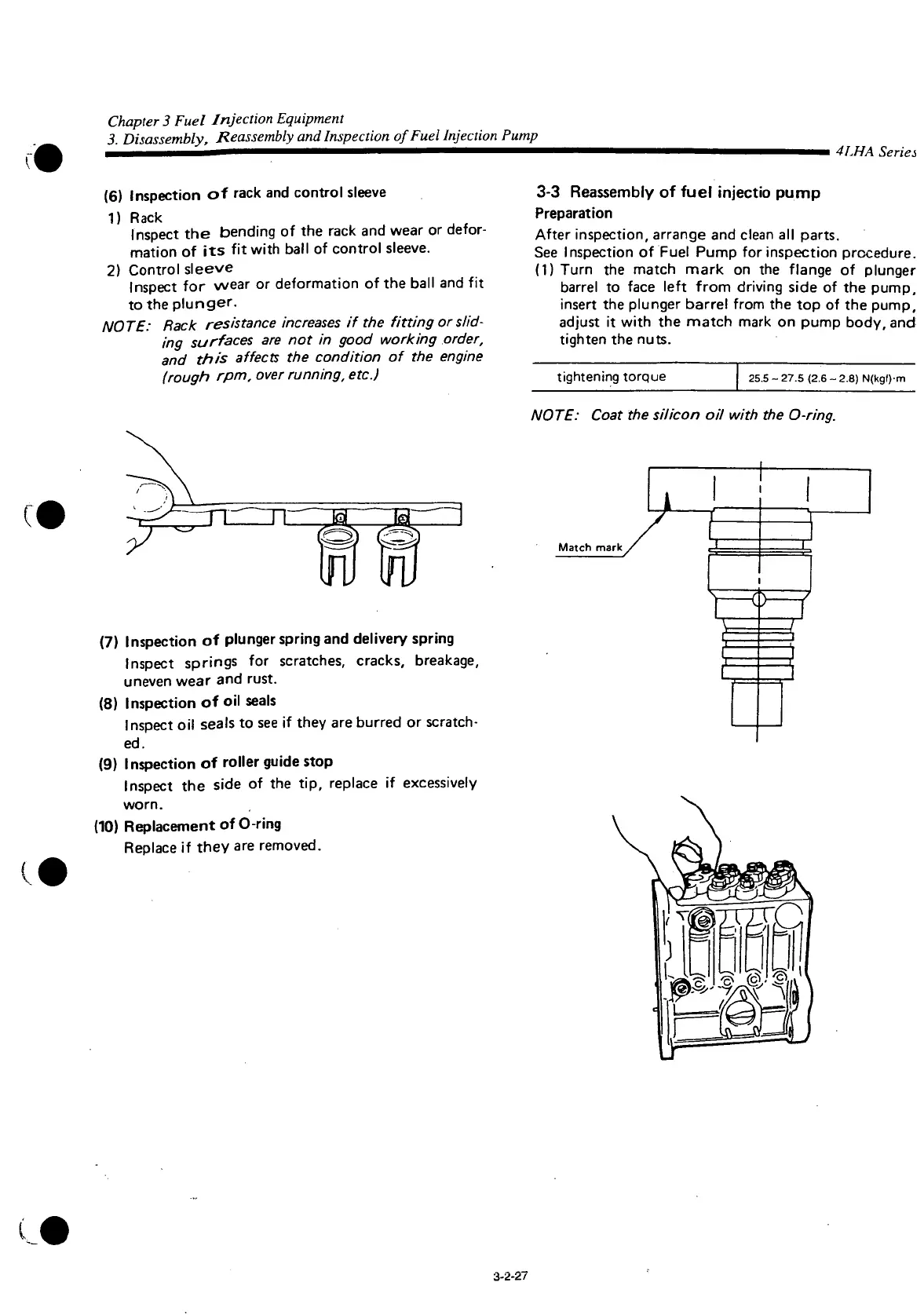

3-3

Reassembly

of fuel injectio pump

Preparation

After inspection, arrange and clean all parts.

See

Inspection of

Fuel

Pump for inspection procedure.

(1) Turn the match mark on the flange of plunger

barrel to face

left

from

driving side of the pump,

insert the plunger barrel

from

the top of the pump,

adjust it

with

the match mark on pump body, and

tighten

the nuts.

tightening torque

25.5

- 27.5 (2.6 - 2.8) N(kgf) m

NOTE: Coat the silicon oil with the O-ring.

3-2-27

Loading...

Loading...