Chapter 3 Fuel Injection Equipment

7. Fuel Injection Nozzle

4LHA Serie

NO TE: Use a special socket wrench for the hole type

(the thickness of the two nozzle nuts is 15

mm (0.5906 in.)).

(4) Remove the inner parts

NOTE: Be careful not to loosen the spring seat, ad-

justing shims or other small parts.

7-4

Fuel

injection

nozzle

inspection

74.1

Washing

(1) Make sure to use new diesel oil to wash the fuel

injection nozzle parts.

(2) Wash the nozzle in clean diesel oil

with

the nozzle

cleaning kit.

Nozzle

cleaning kit

1) Diesel Kiki nozzle cleaning kit:

Type NP-8486B No. 5789-001

2) Anzen Jidosha Co., Ltd. nozzle cleaning kit:

Type NCK-001

(3) Clean off the carbon on the outside of the nozzle

body

with

a brass brush.

(4) Clean the nozzle seat

with

cleaning spray.

(5) Clean off the carbon on the tip of nozzle

with

a

piece of wood.

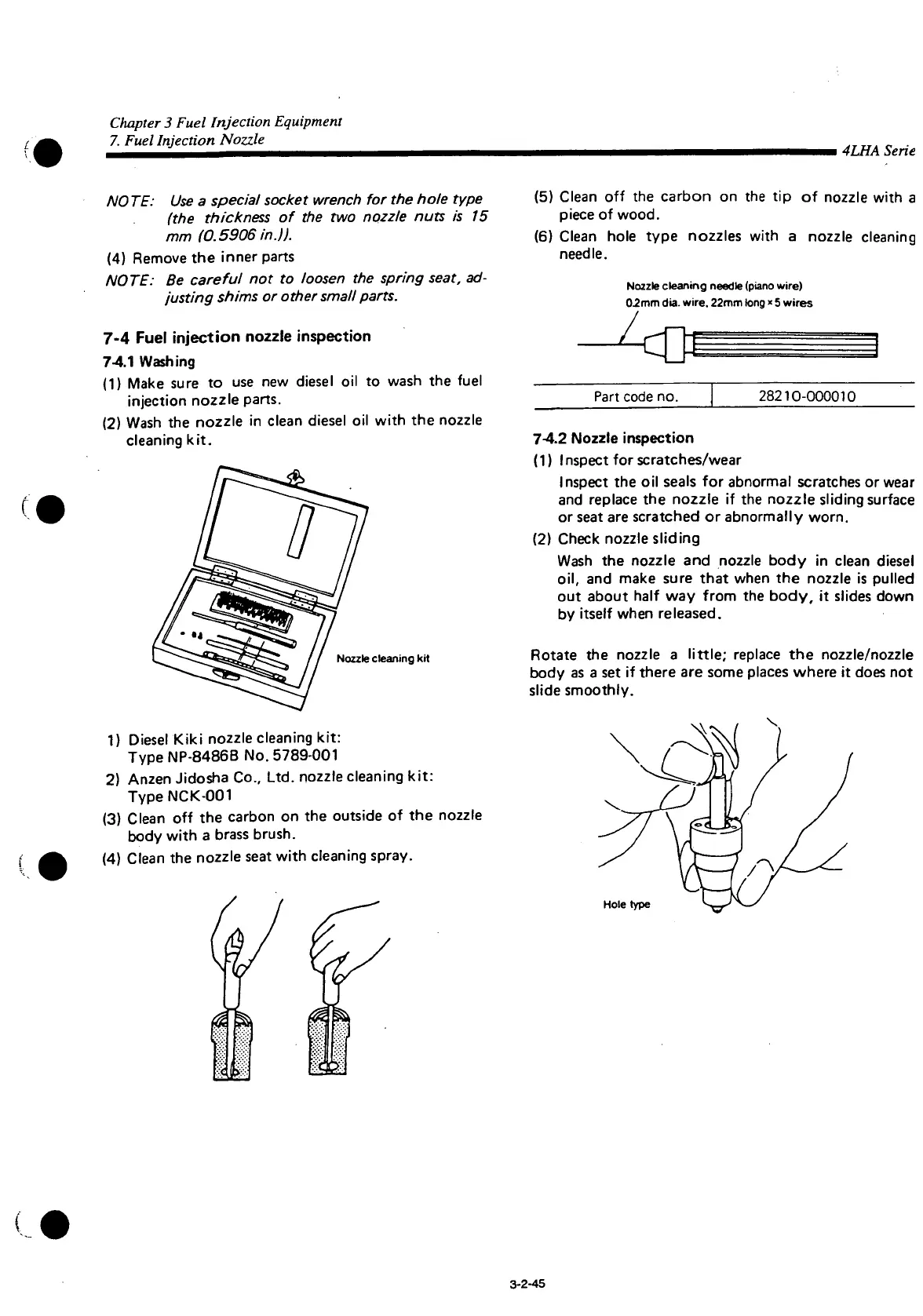

(6) Clean hole type nozzles

with

a nozzle cleaning

needle.

Nozzle

cleaning needle (piano

wire)

02mm dia. wire. 22mm long x 5 wires

z

c i

Part code no. 28210-000010

74.2

Nozzle

inspection

(1)

1

nspect for scratches/wear

Inspect the oil seals for abnormal scratches or wear

and replace the nozzle if the nozzle sliding surface

or seat are scratched or abnormally worn.

(2) Check nozzle sliding

Wash

the nozzle and nozzle body in clean diesel

oil,

and make sure

that

when the nozzle is pulled

out about half way

from

the body, it slides down

by itself when released.

Rotate the nozzle a

little;

replace the nozzle/nozzle

body as a set if there are some places where it does not

slide smoothly.

Hole type

3-2-45

Loading...

Loading...