Chapter 3 Fuel Injection Equipment

7. Fuel Injection Nozzle

4LHA Seriei

7-6.2

Injection

test

After adjusting the nozzle to the specified starting

pressure,

check the fuel spray condition and seat oil

tightness.

(1) Checking the seat oil tightness

After two or three injections, gradually increase

the pressure up to 1.96 (20)

MPa

(kgf/cm). Before

reading the starting pressure, maintain the pressure

for 5 seconds and make sure

that

no oil is dripping

from

the tip of the nozzle.

Test

the injection

with

a nozzle tester, retighten

and

test again if there is excessive oil leakage

from

the overflow coupling.

Replace

the nozzle as a set if oil leakage is still ex-

cessive.

(2)

Injection

spray condition

Operate

the nozzle tester lever once or twice a

second

and check for abnormal injection.

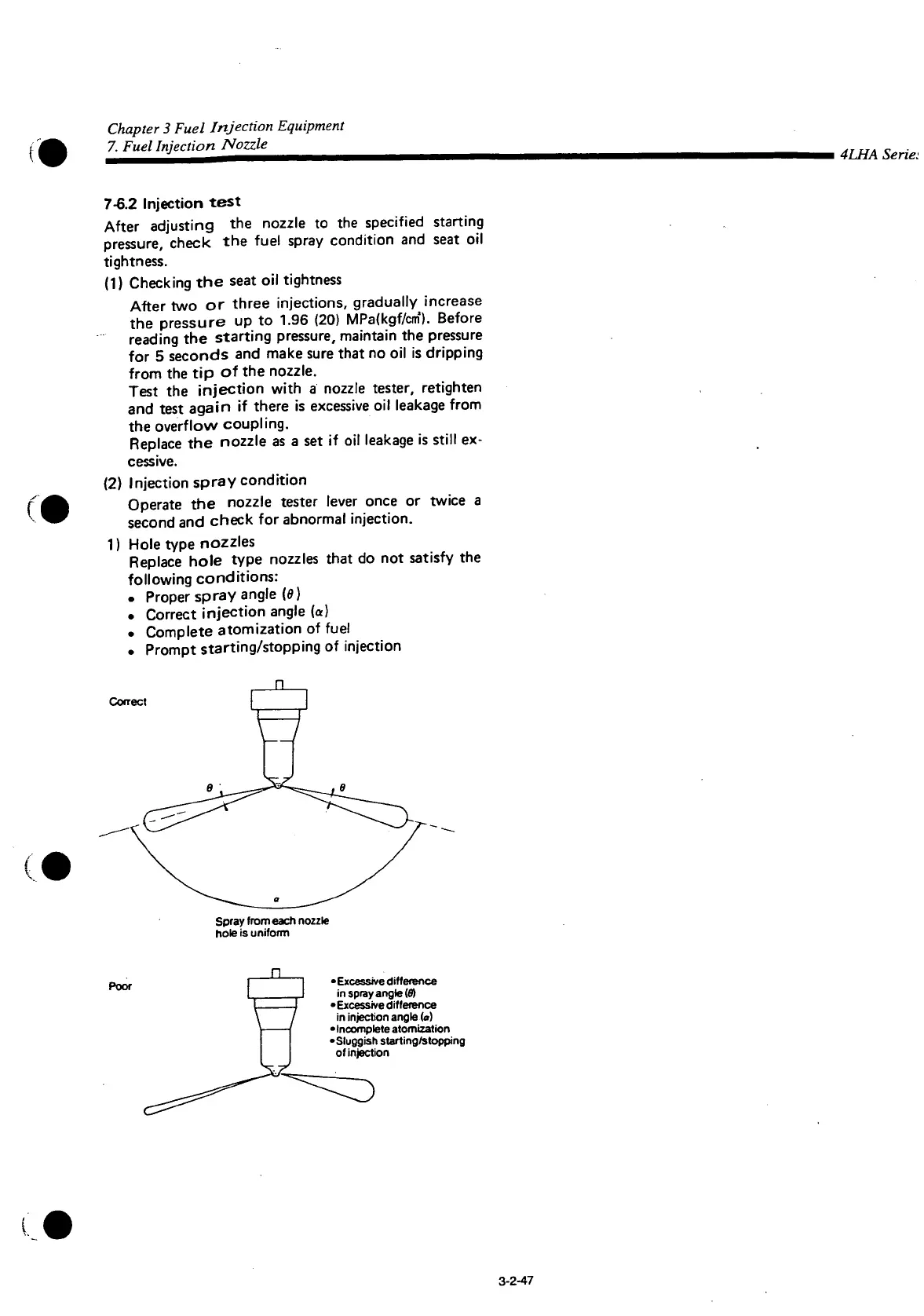

1) Hole type nozzles

Replace hole type nozzles that do not satisfy the

following conditions:

. Proper spray angle {8)

• Correct injection angle (a)

• Complete atomization of fuel

• Prompt starting/stopping of injection

Spray

from

each

nozzle

hole is uniform

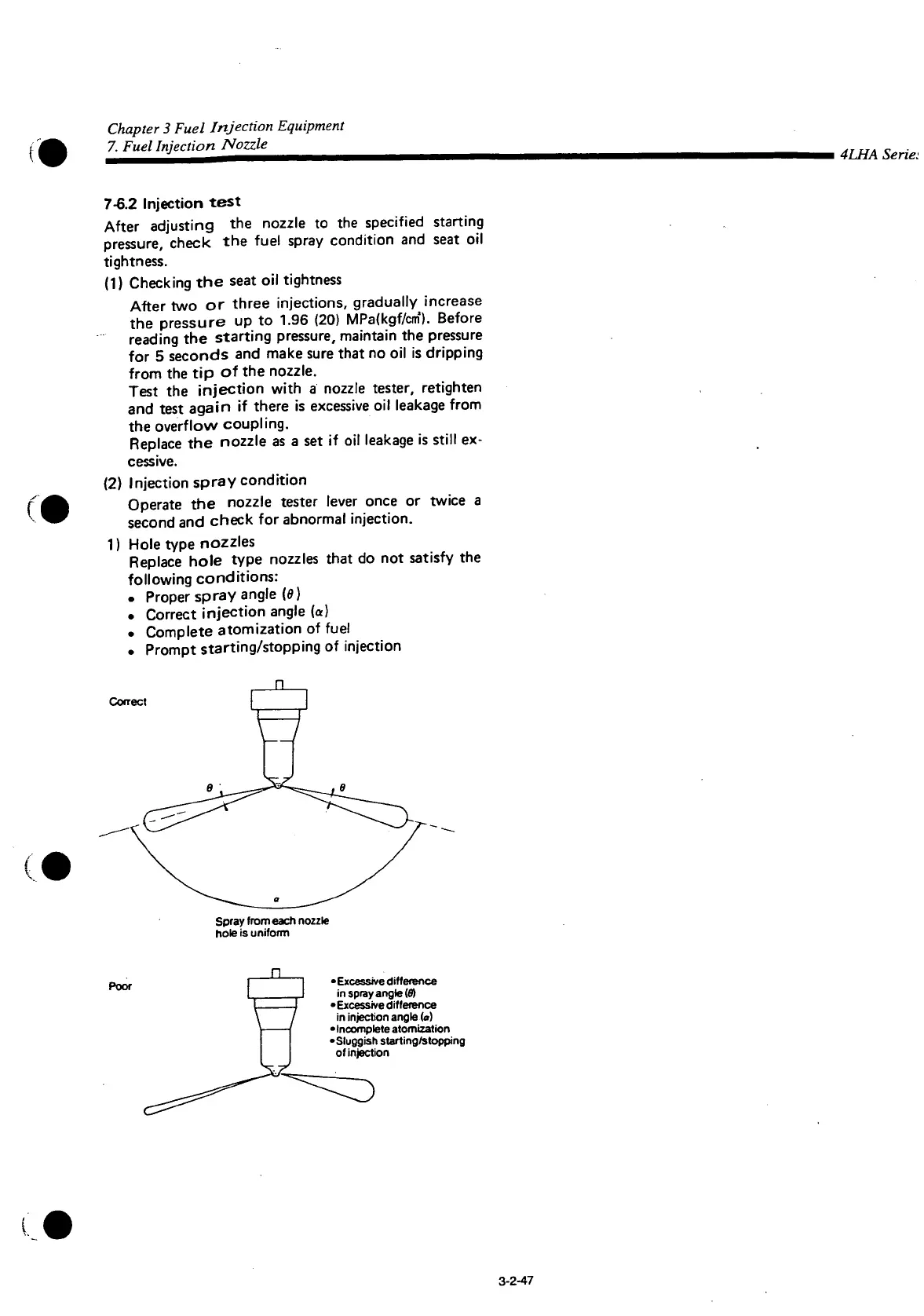

Poor

.TL

•

Excessive

difference

in

spray

angle (9)

•

Excessive

difference

in injection angle (a)

• Incomplete atomization

•Sluggish

starting/stopping

of injection

3-2-47

Loading...

Loading...