Chapter 7 Reduction and Reversing Gear

5. Reassembly

4LHA Serit

5.

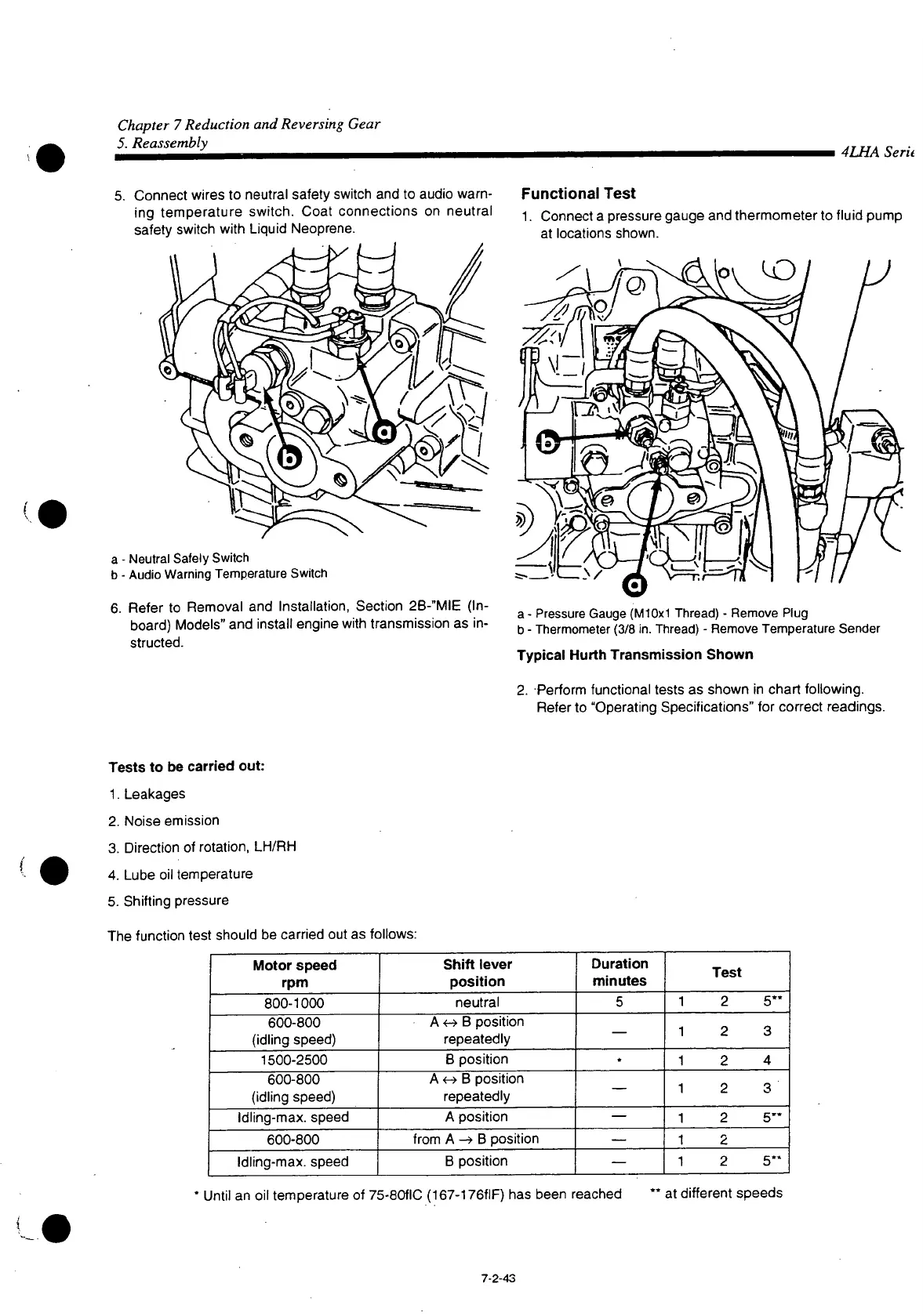

Connect wires to neutral safety switch and to audio warn-

ing temperature switch. Coat connections on neutral

safety switch

with

Liquid Neoprene.

Ax

Functional

Test

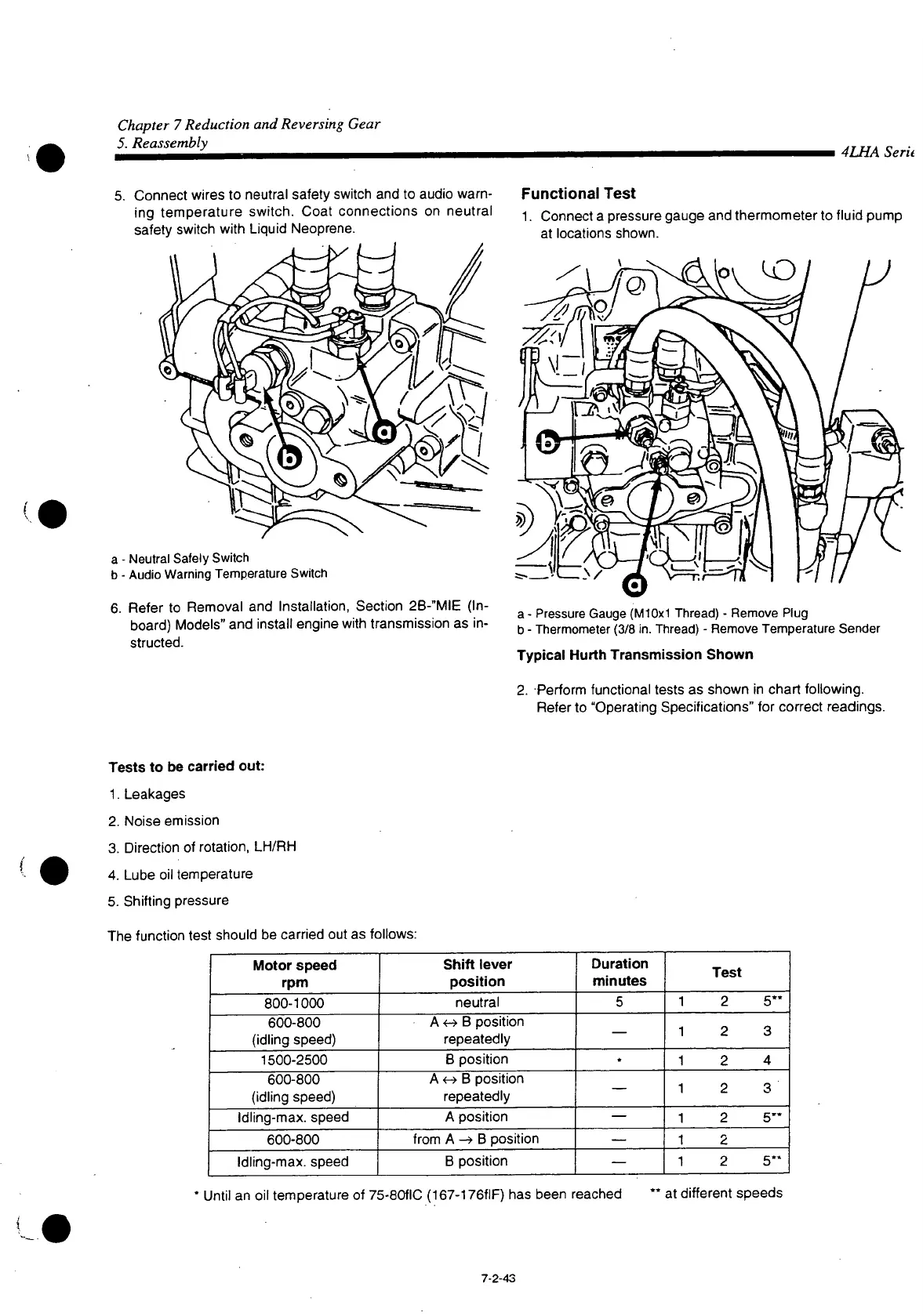

1. Connect a pressure gauge and thermometer to

fluid

pump

at locations shown.

a

- Neutral Safely Switch

b - Audio Warning Temperature Switch

6. Refer to Removal and Installation, Section 2B-"MIE (In-

board)

Models"

and install engine

with

transmission as in-

structed.

a

-

Pressure

Gauge

(Ml0x1

Thread) - Remove Plug

b - Thermometer (3/8 in. Thread) - Remove Temperature Sender

Typical

Hurth

Transmission

Shown

2.

Perform functional tests as shown in chart following.

Refer

to "Operating

Specifications"

for correct readings.

Tests

to be

carried

out:

1. Leakages

2.

Noise emission

3.

Direction of rotation,

LH/RH

4.

Lube oil temperature

5.

Shifting pressure

The

function test should be carried out as follows:

Motor

speed

rpm

Shift

lever

position

Duration

minutes

Test

800-1000

neutral

5

1 2 5"

600-800

(idling

speed)

A

*-> B position

repeatedly

—

1 2 3

1500-2500

B

position

1 2 4

600-800

(idling

speed)

A

<-> B position

repeatedly

—

1 2 3

Idling-max. speed

A

position

—

1 2 5"

600-800

from

A -> B position

—

1 2

Idling-max. speed

B

position

—

1 2 5"

* Until an oil temperature of 75-80flC (167-176flF) has been reached

at

different

speeds

7-2-43

Loading...

Loading...