Chapter 3 Fuel Injection Equipment

5. Injection Pump Construction and Operation

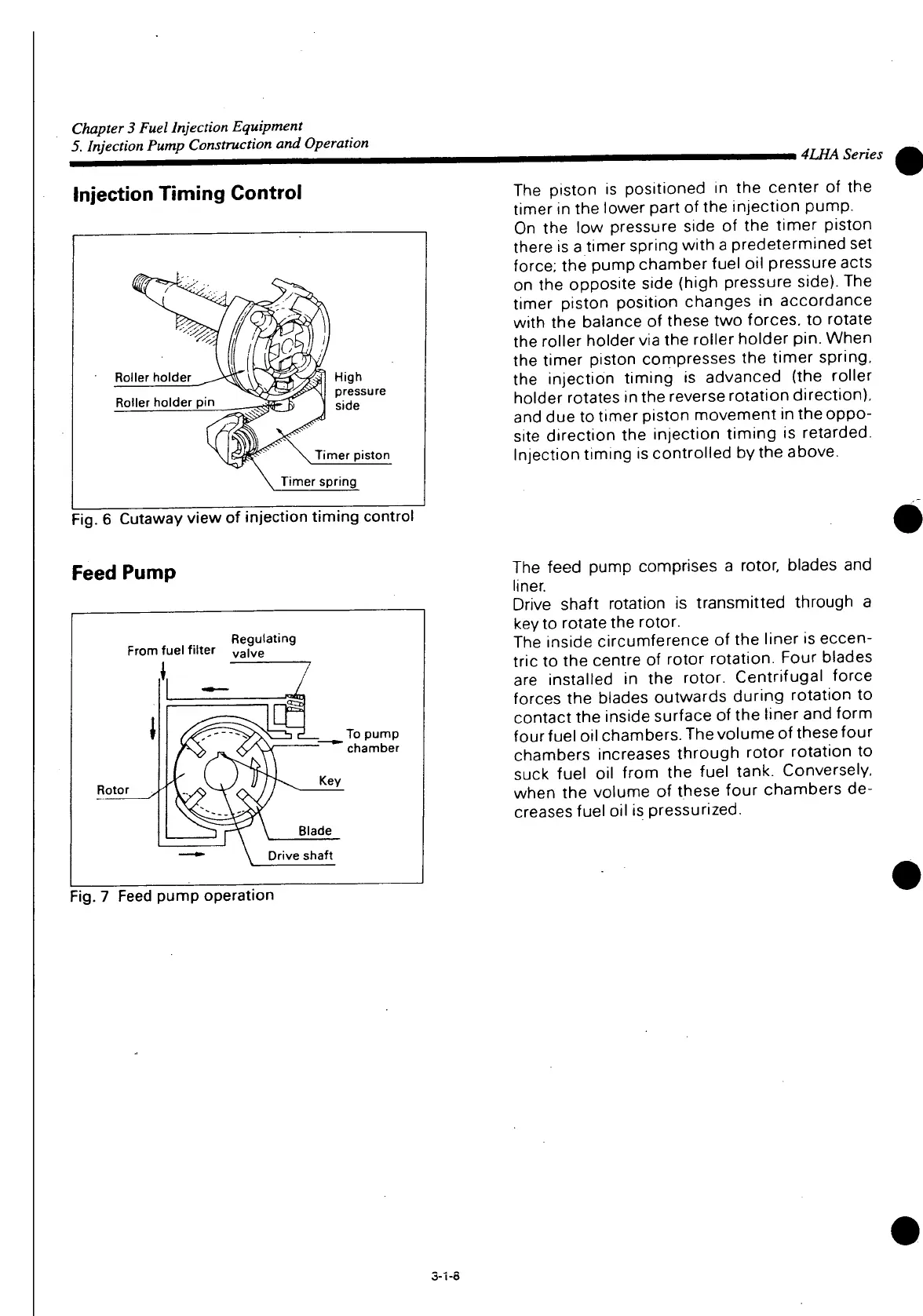

Injection

Timing

Control

Roller

holder

Roller

holder pin

High

pressure

side

Timer piston

Timer spring

i 4LHA Series

The

piston is positioned in the center of the

timer in the lower part of the injection pump.

On

the low pressure side of the timer piston

there is a timer spring

with

a predetermined set

force;

the pump chamber fuel oil pressure acts

on the opposite side (high pressure side). The

timer piston position changes in accordance

with

the balance of these two forces, to rotate

the roller holder via the roller holder pin. When

the timer piston compresses the timer spring,

the injection timing is advanced (the roller

holder rotates in the reverse rotation direction),

and

due to timer piston movement in the oppo-

site direction the injection timing is retarded.

Injection timing is controlled by the above.

:

ig.

6 Cutaway view of injection timing control

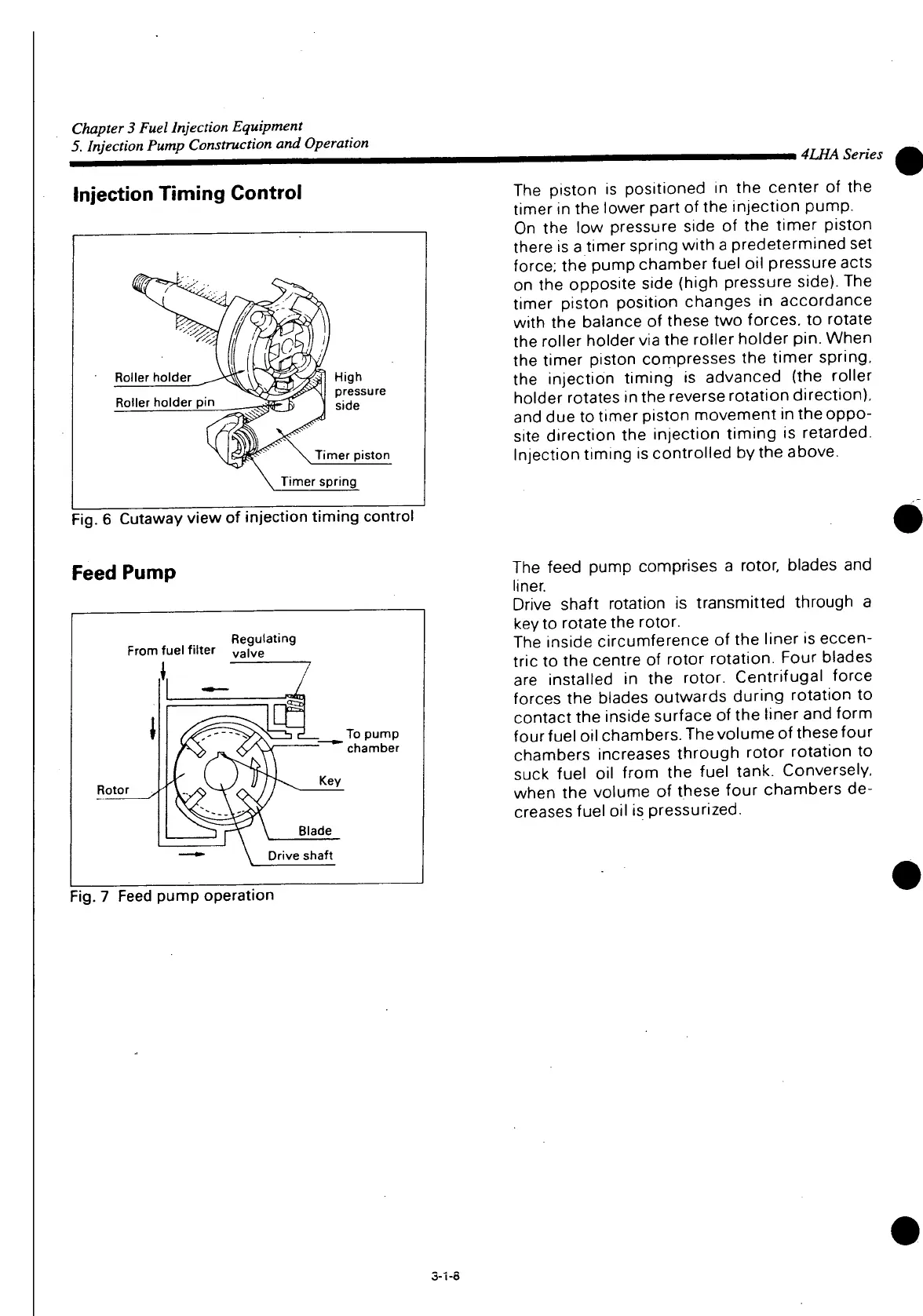

Feed Pump

Regulating

From

fuel

filter

va

|ve

Rotor

To

pump

" chamber

Key

Blade

Drive shaft

Fig.

7

Feed

pump operation

The

feed pump comprises a rotor, blades and

liner.

Drive shaft rotation is transmitted through a

key

to rotate the rotor.

The

inside circumference of the liner is

eccen-

tric to the centre of rotor rotation. Four blades

are installed in the rotor. Centrifugal force

forces

the blades outwards during rotation to

contact the inside surface of the liner and form

four fuel oil chambers. The volume of these four

chambers

increases through rotor rotation to

suck

fuel oil from the fuel tank. Conversely,

when the volume of these four chambers de-

creases

fuel oil is pressurized.

3-1-a

Loading...

Loading...