Chapter 3 Fuel Injection Equipment

7. Fuel Injection Nozzle

i4LHA Series

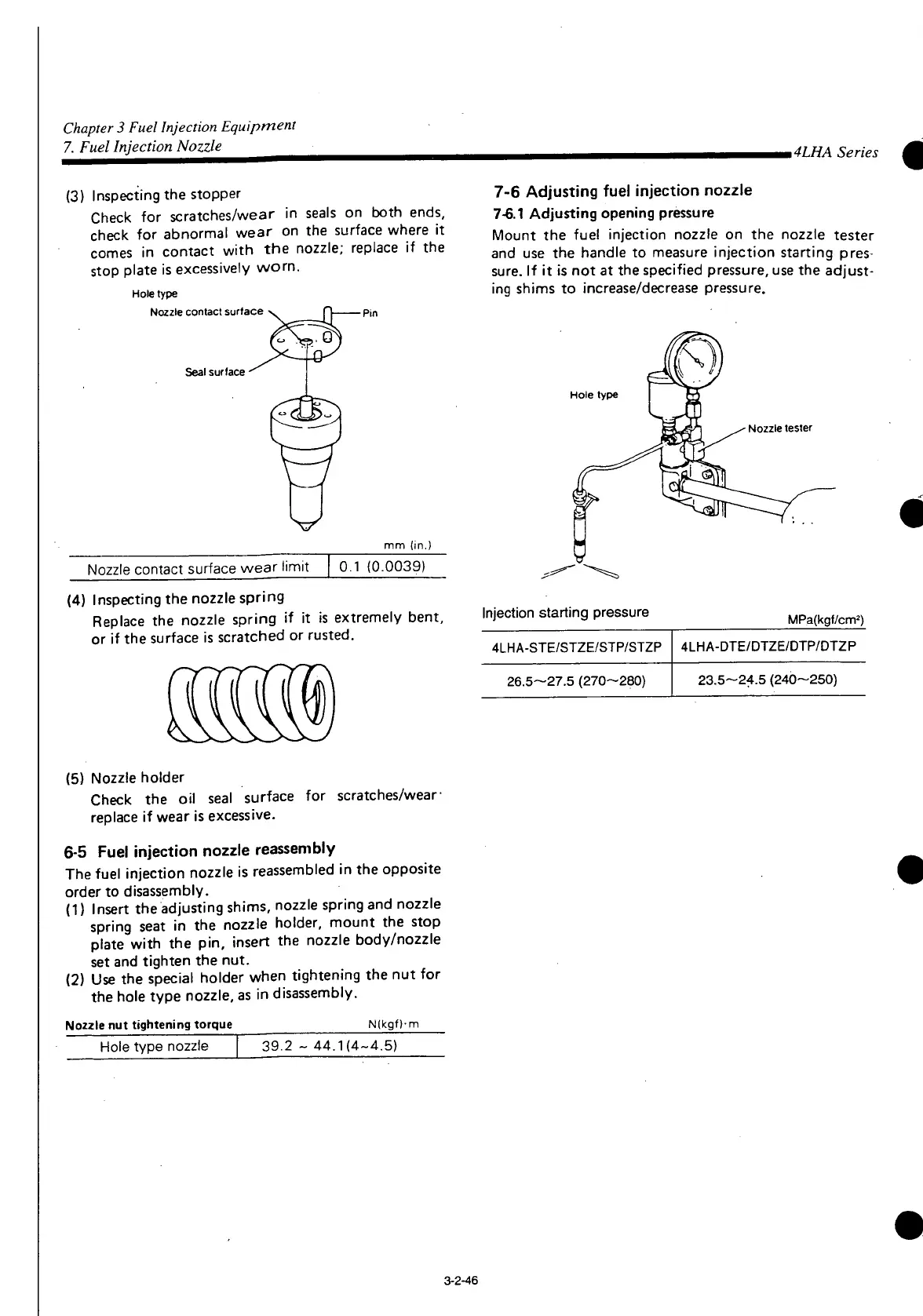

(3) Inspecting the stopper

Check

for scratches/wear in seals on both ends,

check

for abnormal wear on the surface where it

comes

in contact

with

the nozzle; replace if the

stop plate is excessively worn.

Hole

type

Nozzle

contact surface \ fl Pin

Seal

surface

mm (in.)

Nozzle

contact surface wear

limit

0.1 (0.0039)

(4) Inspecting the nozzle spring

Replace

the nozzle spring if it is extremely bent,

or if the surface is scratched or rusted.

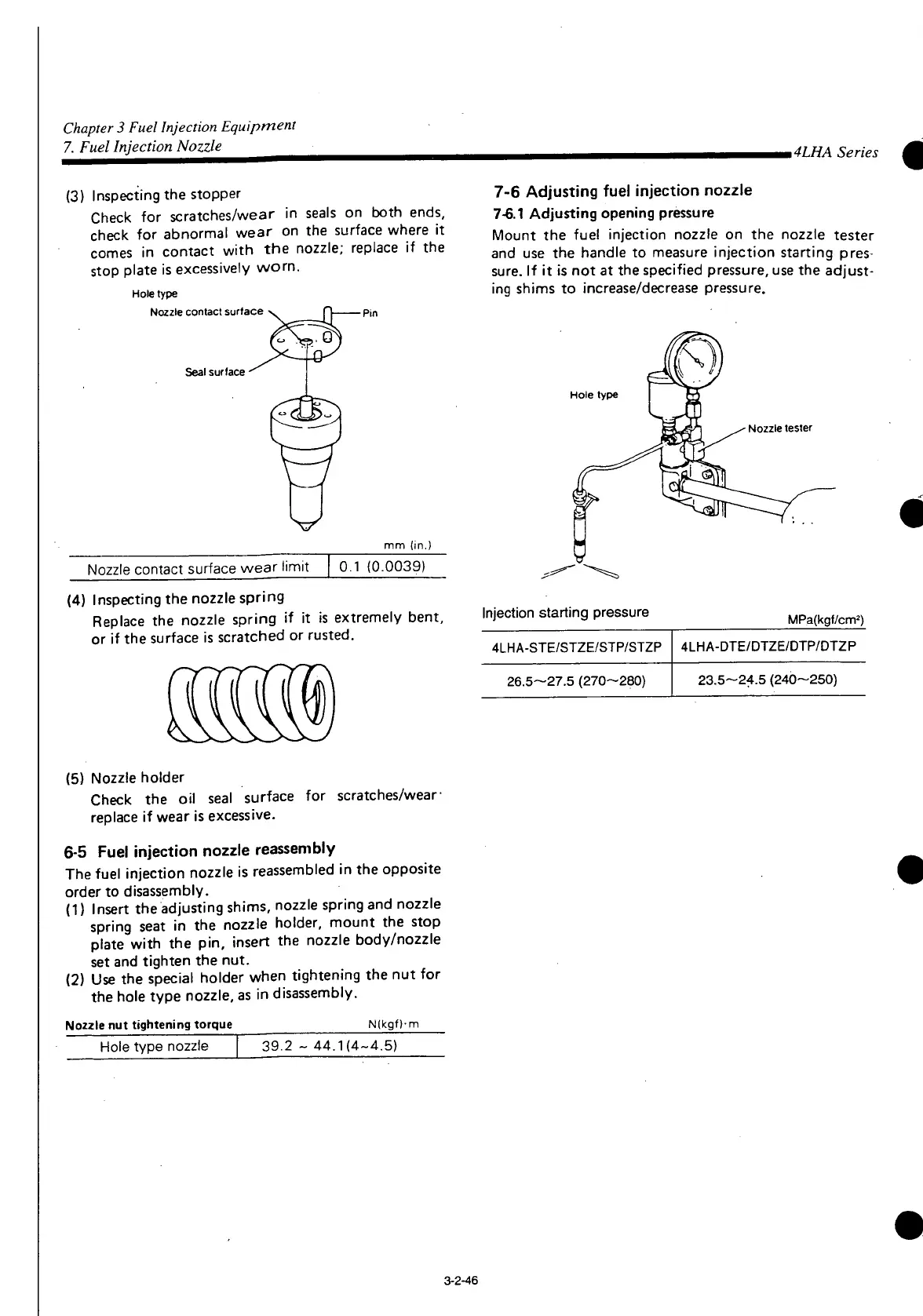

7-6 Adjusting fuel injection nozzle

7-6.1 Adjusting opening pressure

Mount the fuel injection nozzle on the nozzle tester

and

use the handle to measure injection starting pres-

sure.

If it is not at the specified pressure, use the adjust-

ing shims to increase/decrease pressure.

Hole

type

Injection

starting pressure

MPa(kgf/cm

2

)

4LHA-STE/STZE/STP/STZP

4LHA-DTE/DTZE/DTP/DTZP

26.5—27.5

(270-280)

23.5-24.5

(240-250)

(5) Nozzle holder

Check

the oil seal surface for scratches/wear-

replace

if wear is

excessive.

6-5 Fuel

injection

nozzle

reassembly

The

fuel injection nozzle is reassembled in the opposite

order to disassembly.

(1)

Insert

the adjusting shims, nozzle spring and nozzle

spring seat in the nozzle holder, mount the stop

plate

with

the pin, insert the nozzle body/nozzle

set

and tighten the nut.

(2) Use the special holder when tightening the nut for

the hole type

nozzle,

as in disassembly.

Nozzle

nut tightening torque

NlkgO-m

Hole

type nozzle

39

2 - 44.1(4-4.5)

3-2-46

Loading...

Loading...