Chapter 5 Lubrication System

2. Lube Oil Pump

4LHA Sen

2-3 Lube oil

pump

disassembly

(1) Remove the lube oil pump assembly from the engine

plate.

(2) The lube oil pump cover may be disassembled, but

do

not disassemble the rotor, rotor shaft or drive gear.

The

oil pressure regulating valve plug is coated

with

adhesive

and screwed in, so it cannot be

disassembled.

These

parts cannot be reused after disassembly.

Replace

if

necessary

as an assembly.

2-4 Lube oil

pump

inspection

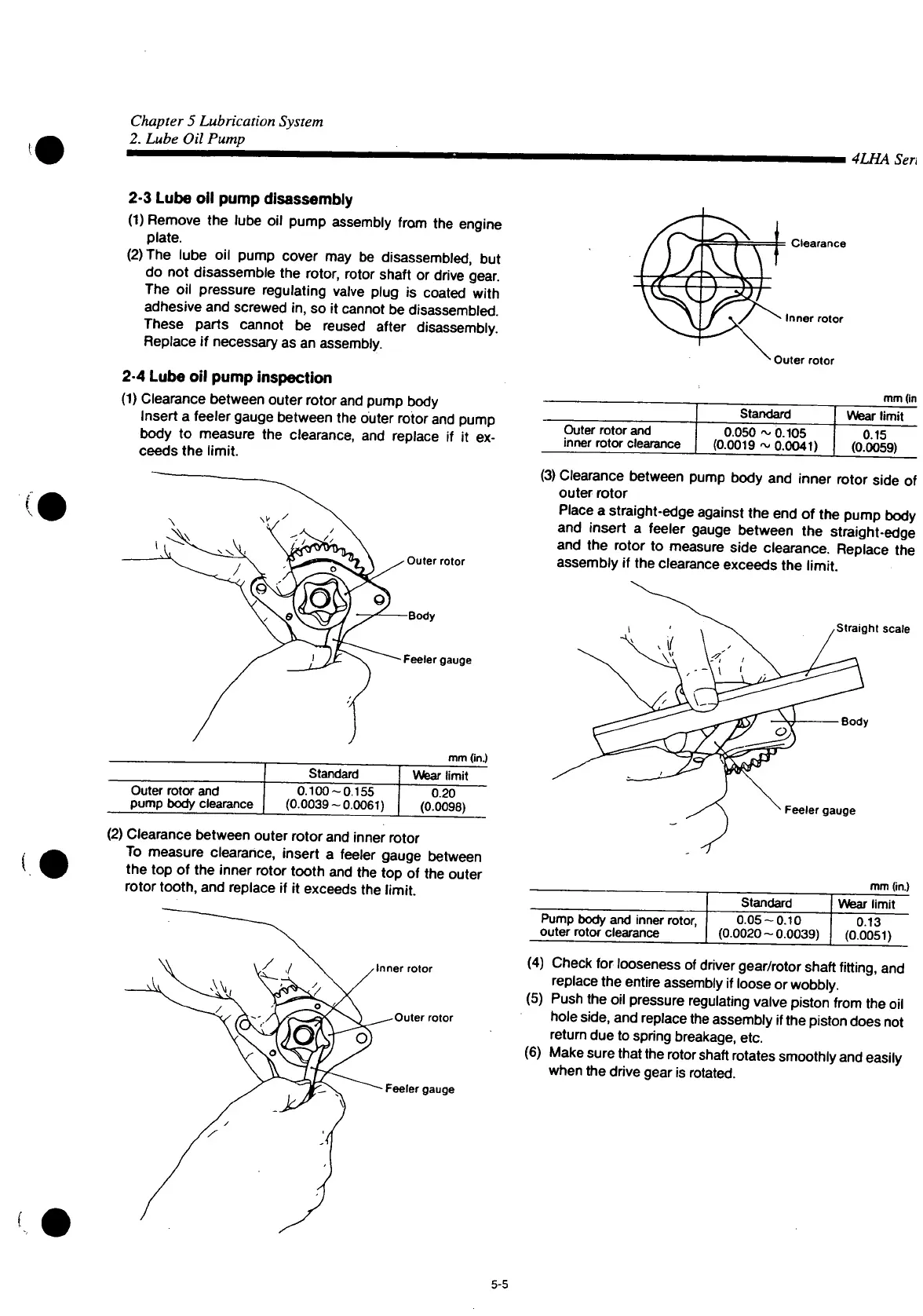

(1)

Clearance

between outer rotor

and

pump body

Insert a feeler gauge between the outer rotor and pump

body

to measure the clearance, and replace if it ex-

ceeds

the

limit.

Outer

rotor

Body

Feeler

gauge

Standard

Wear

limit

Outer

rotor and

pump body clearance

0.100-0.155

(0.0039 - 0.0061)

0.20

(0.0098)

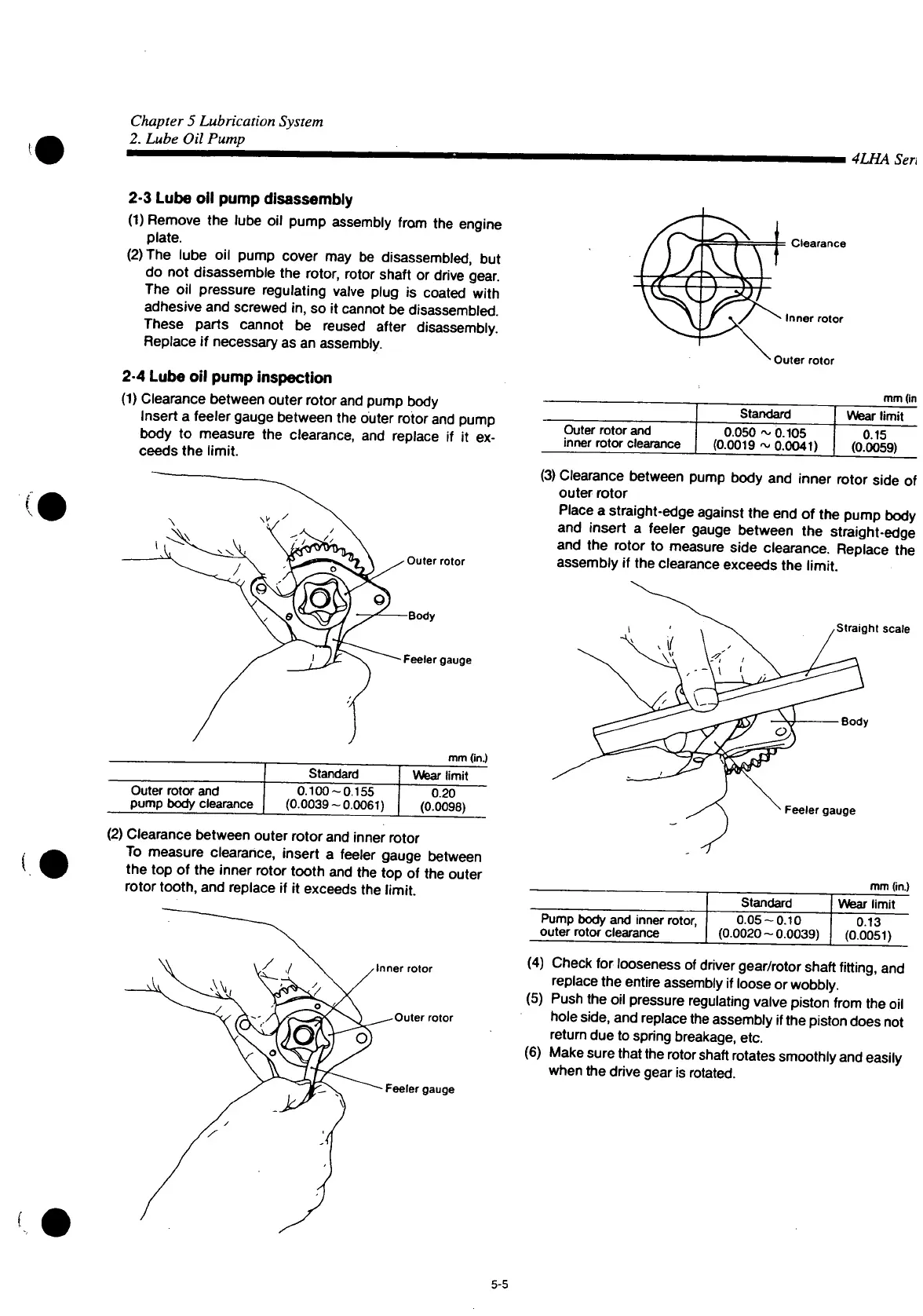

(2)

Clearance

between outer rotor

and

inner rotor

To

measure clearance, insert a feeler gauge between

the top of the inner rotor tooth and the top of the outer

rotor tooth, and replace if it exceeds the

limit.

Inner rotor

Outer

rotor

Feeler

gauge

Clearance

Inner rotor

Outer

rotor

Standard

Wear

limit

Outer

rotor and

inner rotor clearance

0.050 ~ 0.105

(0.0019 ~ 0.0041)

0.15

(0.0059)

(3)

Clearance

between pump body and inner rotor side of

outer rotor

Place

a straight-edge against the end of the pump body

and

insert a feeler gauge between the straight-edge

and

the rotor to measure side clearance.

Replace

the

assembly

if the

clearance

exceeds

the

limit.

Straight

scale

Body

Feeler

gauge

Standard

Wear

limit

Pump

body and inner rotor,

outer rotor clearance

0.05-0.10

(0.0020 - 0.0039)

0.13

(0.0051)

(4)

Check

for

looseness

of driver gear/rotor shaft fitting, and

replace

the entire

assembly

if loose or wobbly.

(5)

Push

the oil pressure regulating valve piston from the oil

hole

side,

and

replace

the

assembly

if the piston does not

return due to spring

breakage,

etc.

(6)

Make

sure

that

the rotor shaft rotates smoothly

and

easily

when the drive gear is rotated.

5-5

Loading...

Loading...