Chapter 7 Reduction

and

Reversing Gear

1. Construction

4LHA Serie:

Marine

Gear

Model

KM

5

A

1.

Construction

1-1

Construction

The

clutch is a cone-type, mechanically operated clutch.

When

the drive cone (which is connected to the clutch shaft

by the lead spline) is moved forward or backward, its taper

contacts

with

the clutch gear and transfers power to the

output

shaft.

The

construction is simple when compared

with

other types

of clutch and it serves to reduces the number of compo-

nents,

making for a lighter, more compact unitwhich can be

operated smoothly. Although it is

small,

the power trans-

mission

efficiency is high even under a heavy

load.

It is

also

durable and reliable because high grade materials are

used

for the shaft and gear, and a taper roller bearing is

incorporated. Power transmission is smooth because

connection

with

the engine is made through the damper

disc.

• The drive cone is made

from

special aluminum bronze

which has high wear-resistance and durability. The

drive cone is connected

with

the clutch shaft. The taper

angle,

diameter of the drive cone,

twist

angle, and

dia-

meter of the involute spline, are designed to give the

greatest efficiency, thus ensuring

that

the drive cone can

be

readily engaged or

disengaged.

•

Helical

gears are used for greater strength. The

inter-

mediate shaft is supported at 2 points to reduce deflec-

tion

and gear noise.

• The clutch

case

and mounting flange are made

from

an

aluminum alloy of special composition to reduce weight.

This

is non-corrosive in seawater.

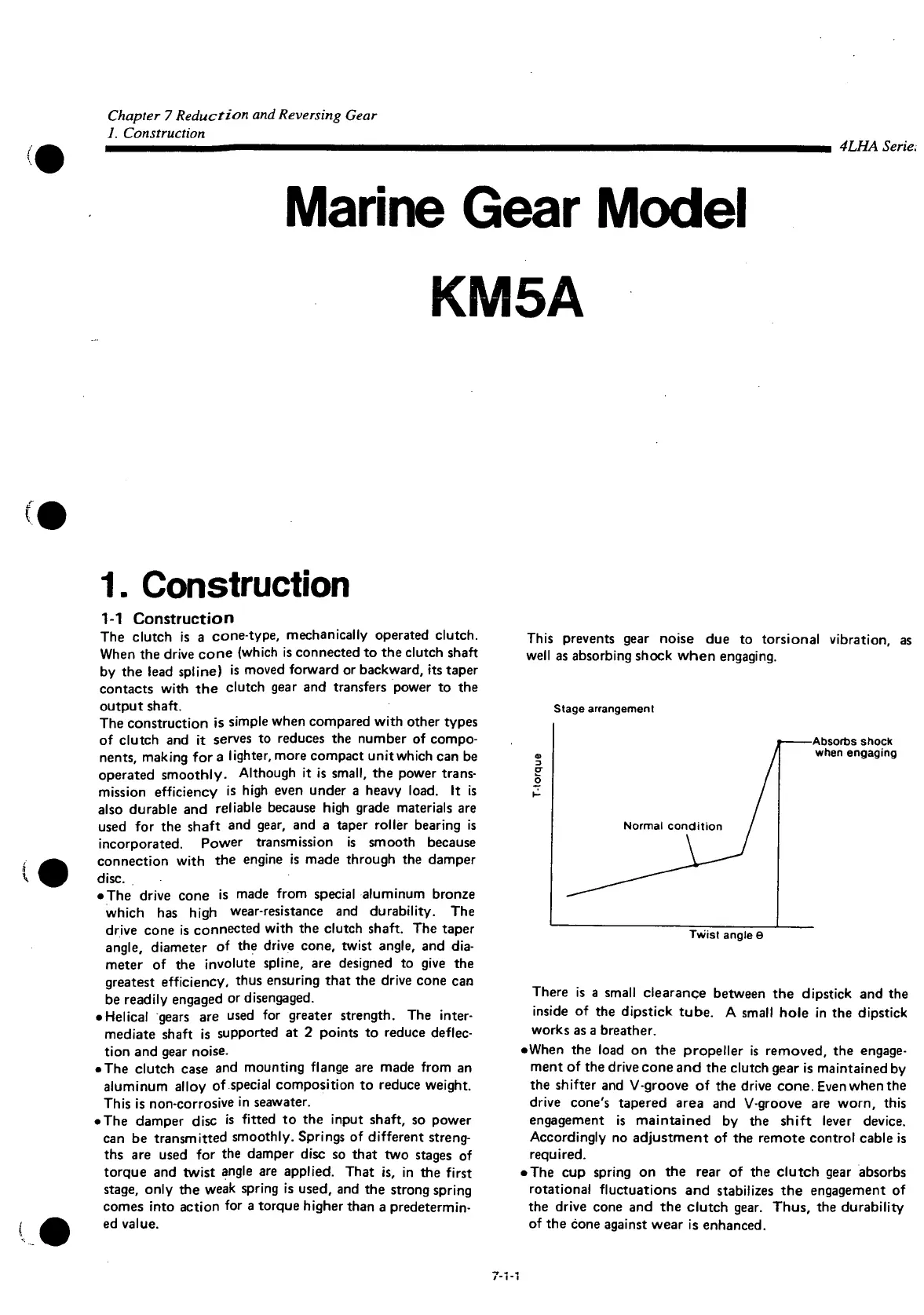

• The damper disc is

fitted

to the

input

shaft, so power

can

be transmitted smoothly. Springs of

different

streng-

ths are used for the damper disc so

that

two stages of

torque and

twist

angle are applied. That is, in the

first

stage,

only the weak spring is

used,

and the strong spring

comes

into

action for a torque higher than a predetermin-

ed

value.

This

prevents gear noise due to torsional vibration, as

well as absorbing shock when engaging.

Stage

arrangement

Absorbs

shock

when engaging

Twist angle 6

There

is a small clearance between the dipstick and the

inside

of the dipstick tube. A small hole in the dipstick

works

as

a breather.

•

When

the load on the propeller is removed, the engage-

ment of the drive cone and the clutch gear is maintained by

the shifter and V-groove of the drive cone.

Even

when the

drive cone's tapered area and V-groove are worn, this

engagement is maintained by the

shift

lever device.

Accordingly

no adjustment of the remote control cable is

required.

• The cup spring on the rear of the clutch gear absorbs

rotational fluctuations and stabilizes the engagement of

the drive cone and the clutch gear. Thus, the durability

of the cone against wear is enhanced.

7-1-1

Loading...

Loading...