5.2.3.4 Automatic Writing into the Work Coordinate

System Shift Memory

The Z-axis work coordinate system shift amount

can automatically be written by the following

operation.

This operation is to be performed after writing

into the tool coordinate memory is completed.

(1) Turn on the measurement mode switch.

m

n

The ~

lamp blinks,

When doing this immediately after writing into

the tool coordinate memory, perform the

following process, after Par. 4.2.3.3 (3) to

(8).

(2) Check that the offset screen displays the

OFFSET (WORK - SHIFT) screen.

(3) Select the tool that can perform end face

cutting on the workpiece.

When manual cursor selection (parameter #6020

D3 = “0’1) is selected,

move the cursor to the

tool coordinate memory number corresponding

to the selected tool.

~

After setting the cursor,

n

depress the ~

function key once more. The offset screen

will display the OFFSET (WORK - SHIFT)

screen.

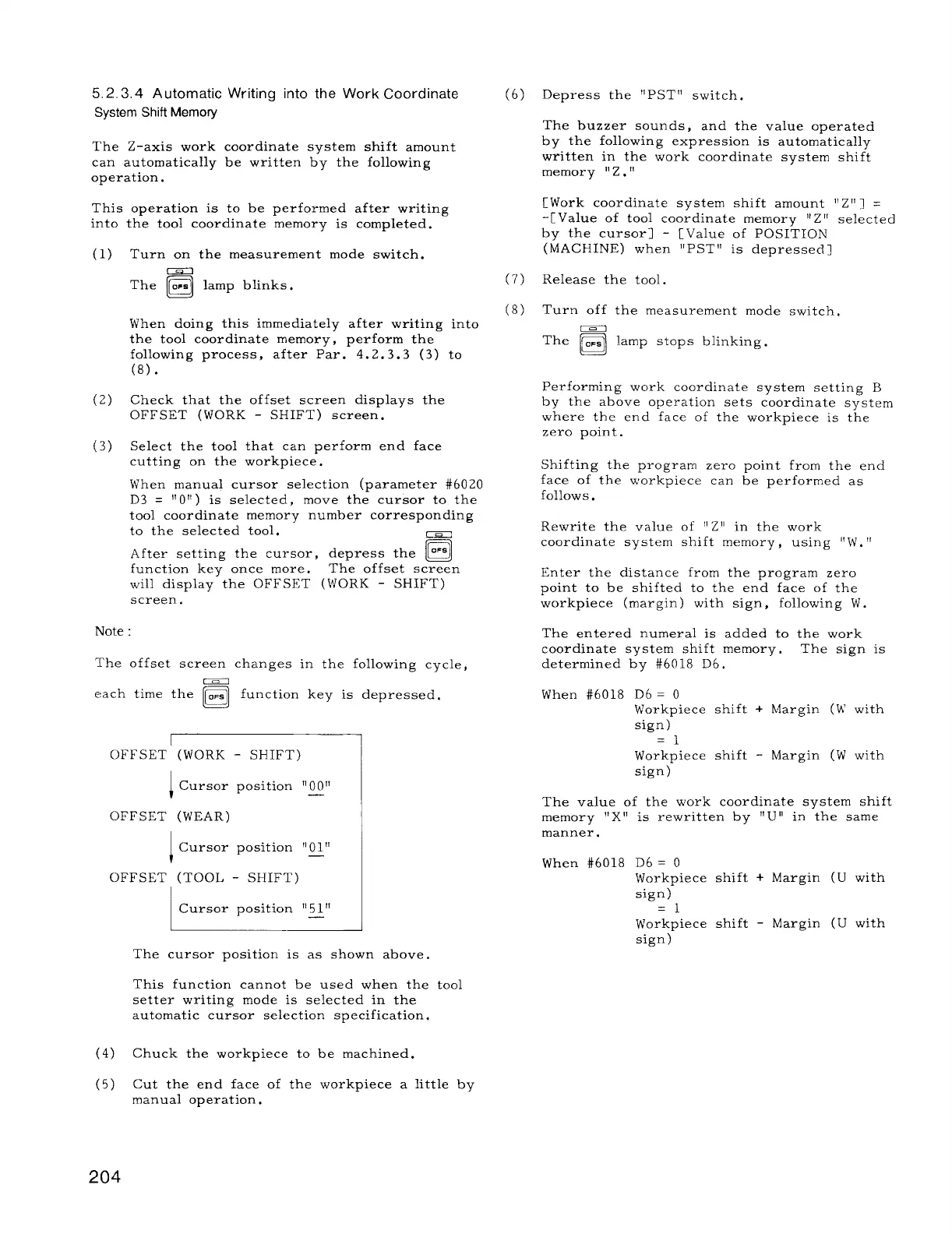

Note :

The offset screen changes in the following cycle,

each time the ~ function key is depressed.

OFFSET (WORK - SHIFT)

I

Cursor position “ 00”

—

OFFSET (WEAR)

I

Cursor position “ 01”

—

OFFSET (TOOL - SHIFT)

Cursor position “ 51”

—

The cursor position is as shown above.

This function cannot be used when the tool

setter writing mode is selected in the

automatic cursor selection specification.

(6)

(7)

(8)

Depress the

“PST” switch.

The buzzer sounds,

and the value operated

by the following expression is automatically

written in the work coordinate system shift

memory “Z.”

[Work coordinate system shift amount ‘tZ“ ] =

-[value of tool coordinate memory “Z” selected

by the cursor] - [Value of POSITION

(MACHINE) when “PST’r is depressed]

Release the tool.

Turn off the measurement

mode switch.

~

c1

The ~

lamp stops blinking .

Performing work coordinate system setting B

by the above operation sets coordinate system

where the end face of the workpiece is the

zero point.

Shifting the program zero point from the end

face of the workpiece can be performed as

follows.

Rewrite the value of “Z“ in the work

coordinate system shift memory, using 11w. 11

Enter the distance from the program zero

point to be shifted to the end face of the

workpiece (margin) with sign, following W.

The entered numeral is added to the work

coordinate system shift memory.

The sign is

determined by #6018 D6.

When #6018 D6 = O

Workpiece shift + h4argin (W with

sign)

=1

Workpiece shift - Margin (W with

sign)

The value of the work coordinate system shift

memory

!!x!! is rewritten

by ‘Iu 1! in the same

manner.

When #6018 D6 = O

Workpiece shift + Margin (U with

sign)

=1

Workpiece shift - Margin (U with

sign)

(4) Chuck the workpiece to be machined,

(5) Cut the end face of the workpiece a little by

manual operation.

Loading...

Loading...