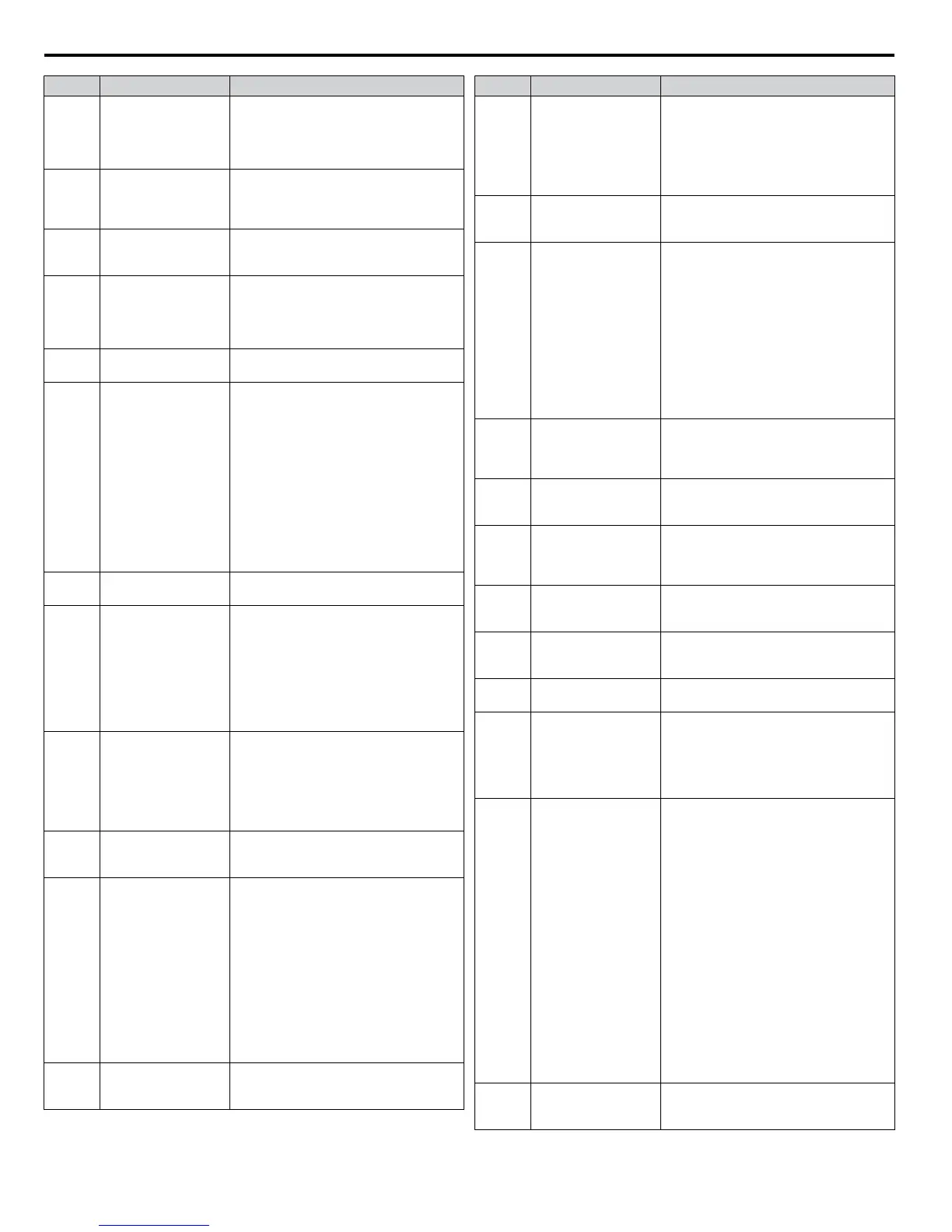

No. Name Description

H5-08

Communication

Protocol Selection

Selects the communication protocol.

0: MEMOBUS/Modbus

1: N2 (Metasys)

2: P1 (APOGEE FLN)

3: BACnet

H5-09 CE Detection Time

Sets the time required to detect a

communications error.

Adjustment may be needed when

networking several drives.

H5-10

Unit Selection for

MEMOBUS/Modbus

Register 0025H

0: 0.1 V units

1: 1 V units

H5-11

Communications

ENTER Function

Selection

0: Drive requires an Enter command

before accepting any changes to

parameter settings.

1: Parameter changes are activated

immediately without the Enter command.

H5-12

Run Command Method

Selection

0: FWD/Stop, REV/Stop

1: Run/Stop, FWD/REV

L1-01

Motor Overload

Protection Selection

0: Disabled

1: General purpose motor (standard fan

cooled)

4: PM motor with variable torque control

The drive may not be able to provide

protection when using multiple motors,

even if overload is enabled in L1-01. Set

L1-01 to 0 and install separate thermal

relays to each motor.

Note: Default setting is

determined by parameter

A1-02, Control Method

Selection.

L1-02

Motor Overload

Protection Time

Sets the motor thermal overload protection

(oL1) time.

L1-03

Motor Overheat Alarm

Operation Selection

(PTC input)

Sets operation when the motor temperature

analog input

(H3-02 or H3-10 = E) exceeds the alarm

level.

0: Ramp to stop

1: Coast to stop

2: Fast Stop (decelerate to stop using the

deceleration time in C1-09)

3: Alarm only (“oH3” will flash)

L1-04

Motor Overheat Fault

Operation Selection

(PTC input)

Sets stopping method when the motor

temperature analog input (H3-02, or H3-10

= E) exceeds the oH4 fault level.

0: Ramp to stop

1: Coast to stop

2: Fast Stop (decelerate to stop using the

deceleration time in C1-09)

L1-05

Motor Temperature

Input Filter Time (PTC

input)

Adjusts the filter for the motor temperature

analog input

(H3-02, or H3-10 = E).

L1-08 oL1 Current Level

Sets the reference current for motor thermal

overload detection for the motor in

amperes.

Note: 1. Available in drive

software versions

PRG: 1016 and later.

2. Default setting is

determined by

parameters o2-04,

Drive Model

Selection, and C6-01,

Drive Duty Selection.

L1-13

Continuous

Electrothermal

Operation Selection

0: Disabled

1: Enabled

2: Enable using Real Time Clock

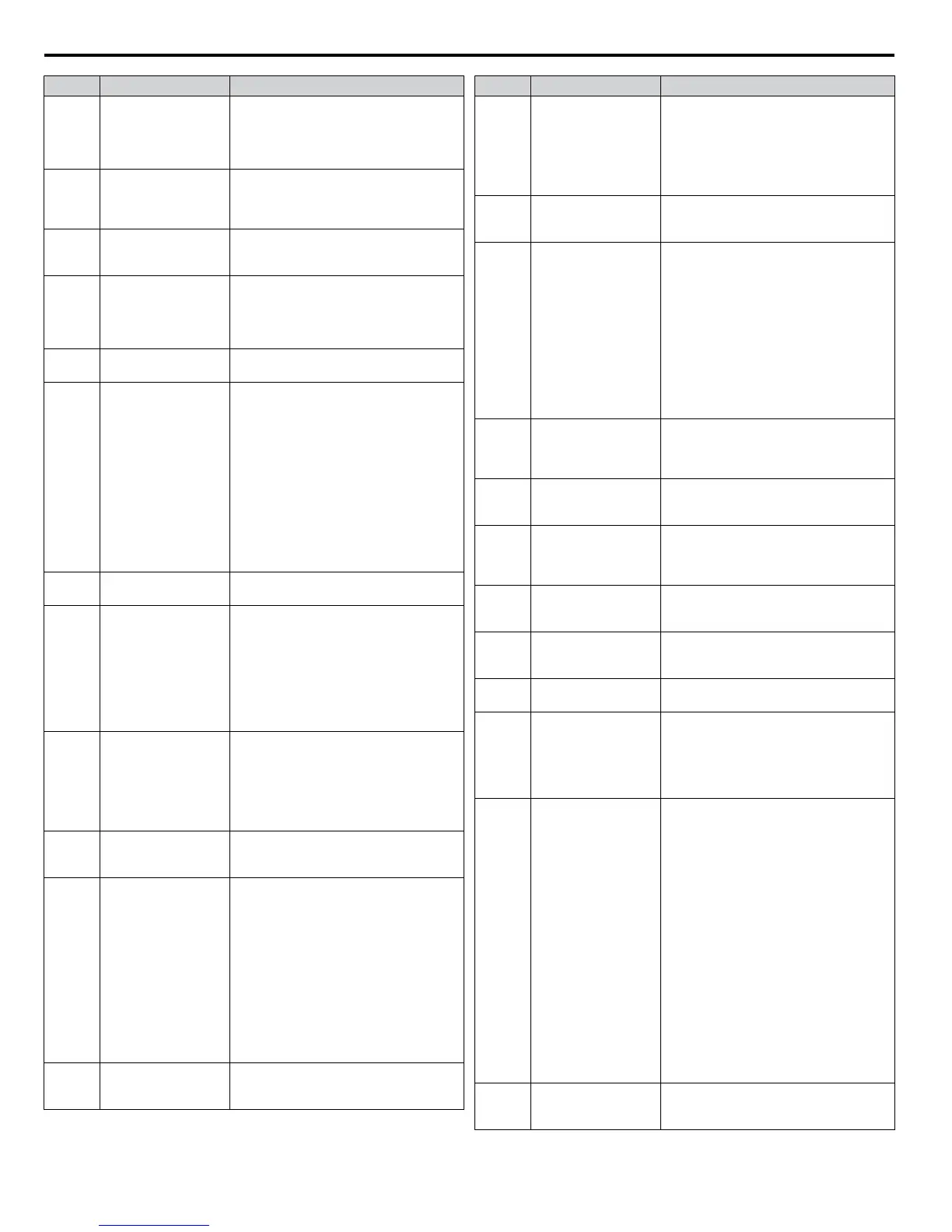

No. Name Description

L2-01

Momentary Power

Loss Operation

Selection

0: Disabled.

Drive trips on Uv1 fault when power is lost.

1: Recover within the time set in L2-02.

Uv1 will be detected if power loss is longer

than L2-02.

2: Recover as long as CPU has power.

Uv1 is not detected.

L2-02

Momentary Power

Loss Ride-Thru Time

Sets the Power Loss Ride-Thru time.

Enabled only when

L2-01 = 1 or 3.

L2-03

Momentary Power

Loss Minimum

Baseblock Time

Sets the minimum wait time for residual

motor voltage decay before the drive output

reenergizes after performing Power Loss

Ride-Thru.

Increasing the time set to L2-03 may help if

overcurrent or overvoltage occur during

Speed Search or during DC Injection

Braking.

Note: Default setting is

dependent on parameter

o2-04, Drive Model

Selection.

L4-05

Frequency Reference

Loss Detection

Selection

0: Stop. Drive stops when the frequency

reference is lost.

1: Run. Drive runs at a reduced speed

when the frequency reference is lost.

L4-06

Frequency Reference

at Reference Loss

Sets the percentage of the frequency

reference that the drive should run with

when the frequency reference is lost.

L5-01

Number of Auto

Restart Attempts

Sets the number of times the drive may

attempt to restart after the following faults

occur: GF, LF, oC, ov, PF, oL1, oL2, oL3,

STo, Uv1.

L5-02

Auto Restart Fault

Output Operation

Selection

0: Fault output not active.

1: Fault output active during restart attempt.

L5-03

Time to Continue

Making Fault Restarts

Enabled only when L5-05 is set to 0. Causes

a fault if a fault restart cannot occur after the

set time passes.

L5-04

Fault Reset Interval

Time

Sets the amount of time to wait between

performing fault restarts.

L5-05

Fault Reset Operation

Selection

0: Continuously attempt to restart while

incrementing restart counter only at a

successful restart.

1: Attempt to restart with the interval

time set in L5-04 and increment the

restart counter with each attempt.

L6-01

Torque Detection

Selection 1

0: Disabled

1: oL3 detection only active during speed

agree, operation continues after detection

2: oL3 detection always active during run,

operation continues after detection

3: oL3 detection only active during speed

agree, output shuts down on an oL3 fault

4: oL3 detection always active during run,

output shuts down on an oL3 fault

5: UL3 detection only active during speed

agree, operation continues after detection

6: UL3 detection always active during run,

operation continues after detection

7: UL3 detection only active during speed

agree, output shuts down on an oL3 fault

8: UL3 detection always active during run,

output shuts down on an oL3 fault

9: UL6 at speed agree (alarm)

10: UL6 at run (alarm)

11: UL6 at speed agree (fault)

12: UL6 at run (fault)

L6-02

Torque Detection

Level 1

Sets the overtorque and undertorque

detection level.

i.8 Parameter Table

74

YASKAWA ELECTRIC TOEP C710616 54A YASKAWA AC Drive - Z1000 Quick Start Guide

Loading...

Loading...