INSTALLATION

INPUT POWER CONNECTION

Check the input voltage, phase, and frequency supplied to

this machine before turning it on. The allowable input voltage

of this machine is 1IOV, which is indicated in the technical

specification section of this manual and on the rating plate of

the machine. Be sure that the machine is grounded.

Make sure the power available at the input connection is ade-

quate for normal operation Ofthe machine

OUTPUT CONNECTIONS

A quick disconnect system using quick cable plugs is used

for the welding cable connections. Refer to the following sec-

tions for more information on connecting the machine for op

eration of flux-core welding, stick welding or TIG welding.

A WARNING

ELECTRIC SHOCK can kill.

• Keep the electrode holder and cable in-

sulation in good condition.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Turn the input line Switch on the

FLUX-135PRO "off" before connecting

or disconnecting output cables or

other equipment.

FLUX-CORE WELDING

Select a suitable filler wire according to process being used

(W type drive roll for gasless flux cored welding). The wire di-

ameter must be matched to the drive roll, the liner and con-

tact tip

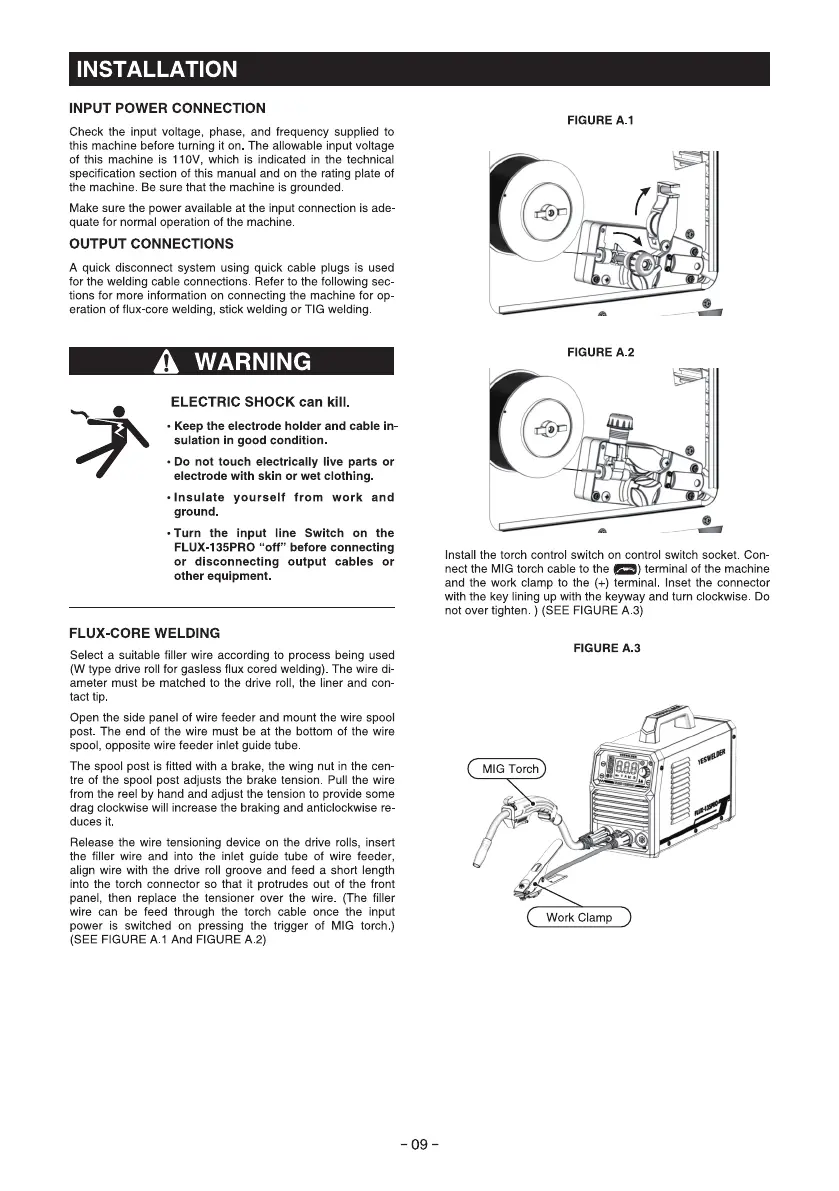

Open the side panel of wire feeder and mount the wire spool

post The end Of the wire must be at the bottom Of the Wlre

spool, opposite wire feeder inlet guide tube

The spool post is fitted with a brake, the wing nut in the cen-

tre of the spool post adjusts the brake tension. Pull the wire

from the reel by hand and adjust the tension to provide some

drag clockwise will increase the braking and anticlockwise re-

duces it

Release the wire tensioning device on the drive rolls, insert

the filler wire and into the inlet guide tube of wire feeder,

align wire with the drive roll groove and feed a short length

into the torch connector so that it protrudes out of the front

panel, then replace the tensioner over the wire. (The filler

wire can be feed through the torch cable once the input

power is switched on pressing the trigger Of MIG torch.)

(SEE FIGURE A 1 And FIGURE A.2)

FIGURE A.I

FIGURE A.2

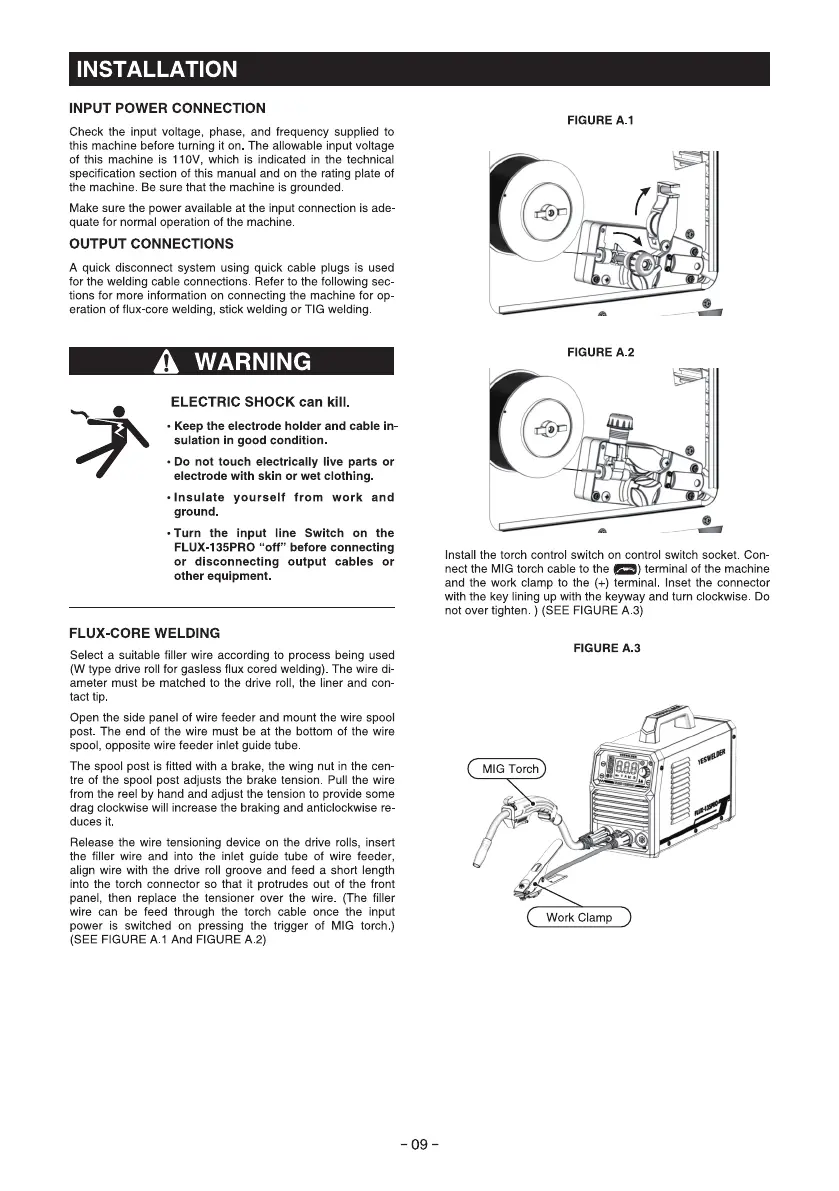

Install the torch control switch on control switch socket. Con

nect the MIG torch cable to the e) terminal of the machine

and the work clamp to the (+) terminal. Inset the connector

with the key lining up with the kepvay and turn clockwise. Do

not over tighten. ) (SEE FIGURE A.3)

FIGURE A.3

MIG Torch

Work Clamp

- 09 -

Loading...

Loading...