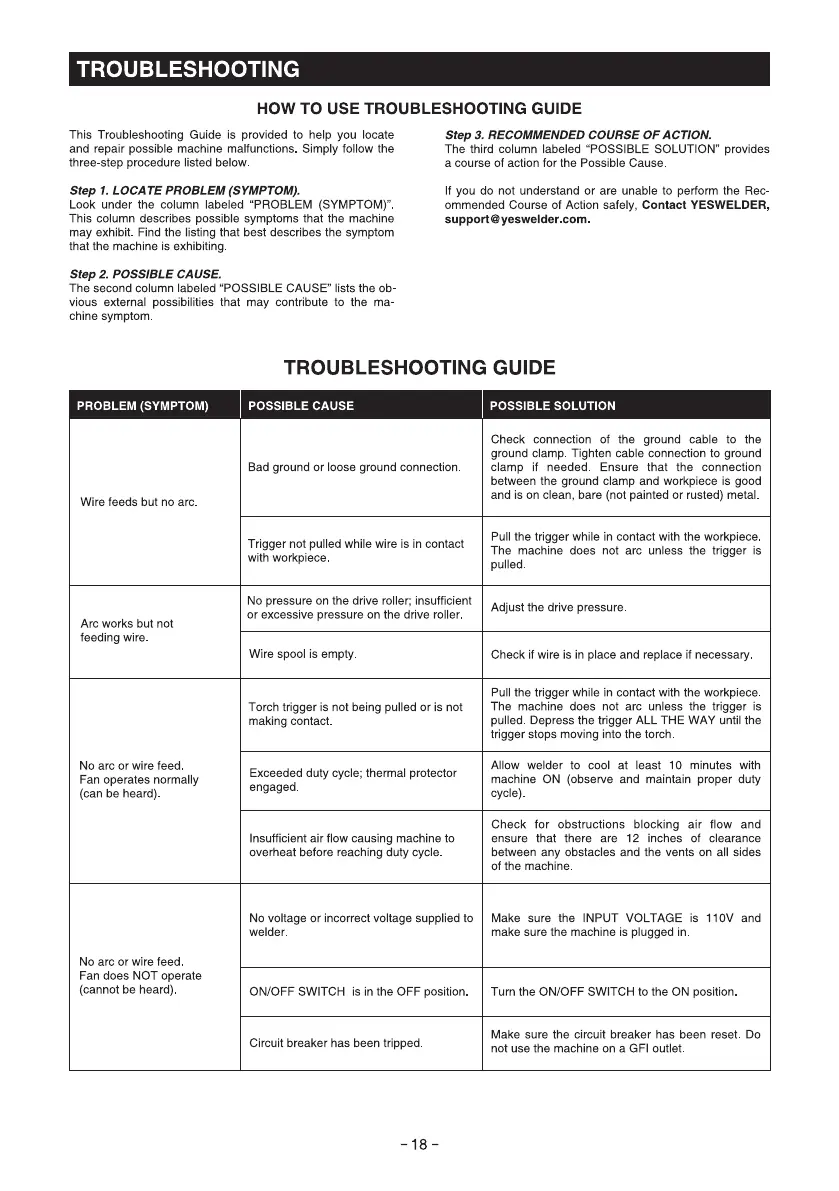

TROUBLESHOOTING

HOW TO USE TROUBLESHOOTING GUIDE

This Troubleshooting Guide is provided to help you locate

and repair possible machine malfunctions. Simply follow the

three step procedure listed below.

step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled "PROBLEM (SYMPTOM)"

This column describes possible symptoms that the machine

may exhibit. Find the listing that best describes the symptom

that the machine is exhibiting

step 2. POSSIBLE CAUSE.

The second column labeled "POSSIBLE CAUSE" lists the ob-

vious external possibilities that may contribute to the ma

step 3. RECOMMENDED COURSE OF ACTION.

The third column labeled "POSSIBLE SOLUTION" provides

a course of action for the Possible Cause

If you do not understand or are unable to perform the Rec-

ommended Course of Action safely, Contact YESWELDER,

support@yeswelder.com.

chine symptom

PROBLEM (SYMPTOM)

Wire feeds but no arc

Arc works but not

feeding wire

No arc or wire feed

Fan operates normally

(can be heard)

NO arc Or wire feed

Fan does NOT operate

(cannot be heard)

TROUBLESHOOTING GUIDE

POSSIBLE CAUSE

Bad ground or loose ground connection.

Trigger not pulled while wire is in contact

with workpiece.

No pressure on the drive roller; insufficient

or excessive pressure on the drive roller.

Wire spool is empty

Torch trigger is not being pulled or is not

making contact.

Exceeded duty cycle; thermal protector

engaged.

Insufficient air flow causing machine to

overheat before reaching duty cycle

NO voltage or incorrect voltage supplied to

welder.

ON/OFF SWITCH is in the OFF position

Circuit breaker has been tripped

-18-

POSSIBLE SOLUTION

Check connection of the ground cable to the

ground clamp Tighten cable connection to ground

clamp if needed. Ensure that the connection

between the ground clamp and workpiece is good

and is on clean, bare (not painted or rusted) metal.

Pull the trigger while in contact with the workpiece.

The machine does not arc unless the trigger is

pulled

Adjust the drive pressure.

Check if wire is in place and replace if necessary

Pull the trigger while in contact with the workpiece

The machine does not arc unless the trigger is

pulled Depress the trigger ALL THE WAY until the

trigger stops moving into the torch.

Allow welder to cool at least 10 minutes with

machine ON (observe and maintain proper duty

cycle)

Check for obstructions blocking air flow and

ensure that there are 12 inches of clearance

between any obstacles and the vents on all sides

of the machine.

Make sure the INPUT VOLTAGE is 1IOV and

make sure the machine is plugged in

Turn the ON/OFF SWITCH to the ON position

Make sure the circuit breaker has been reset. DO

not use the machine on a GFI outlet.

Loading...

Loading...