IM 01E20D01-01E

3-9

3. INSTALLATION

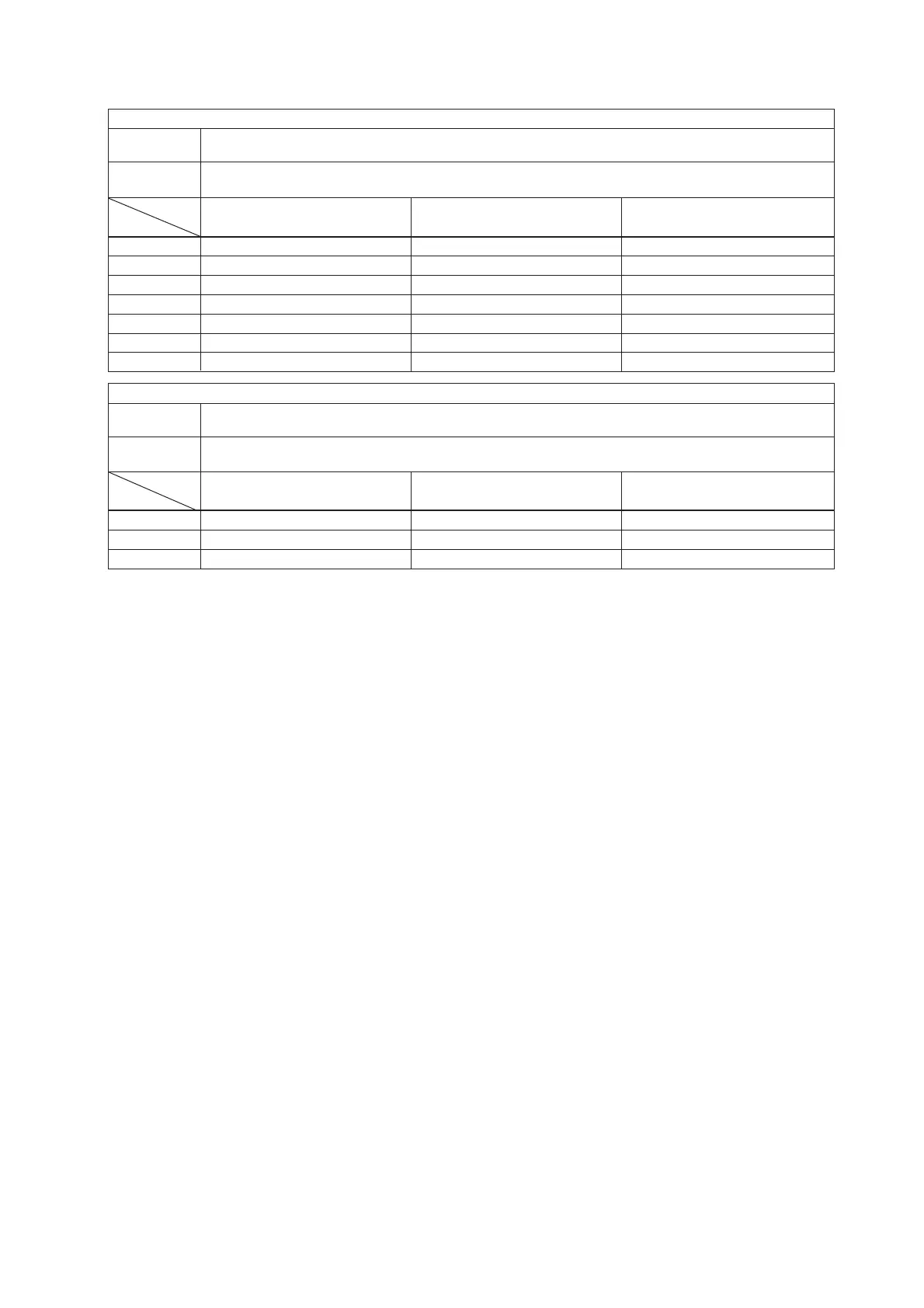

Table 3.3.6 Wafer Type Tightening Torque Values for Metal Piping and Permeable Fluids

JIS 10K, ANSI Class 150, and DIN PN10 JIS 20K, ANSI Class 300, and DIN PN16 DIN PN40

15 (0.5)

25 (1.0)

40 (1.5)

Tightening torque values for Ceramics lining type

(N-m / {kgf-cm} / [in-lbf])

Flange ratings

Size

mm (inch)

PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Fluororesin with ceramic fillers (Valqua #7020) gasket (standard), or fluororesin with carbon gasket (optional code GF)

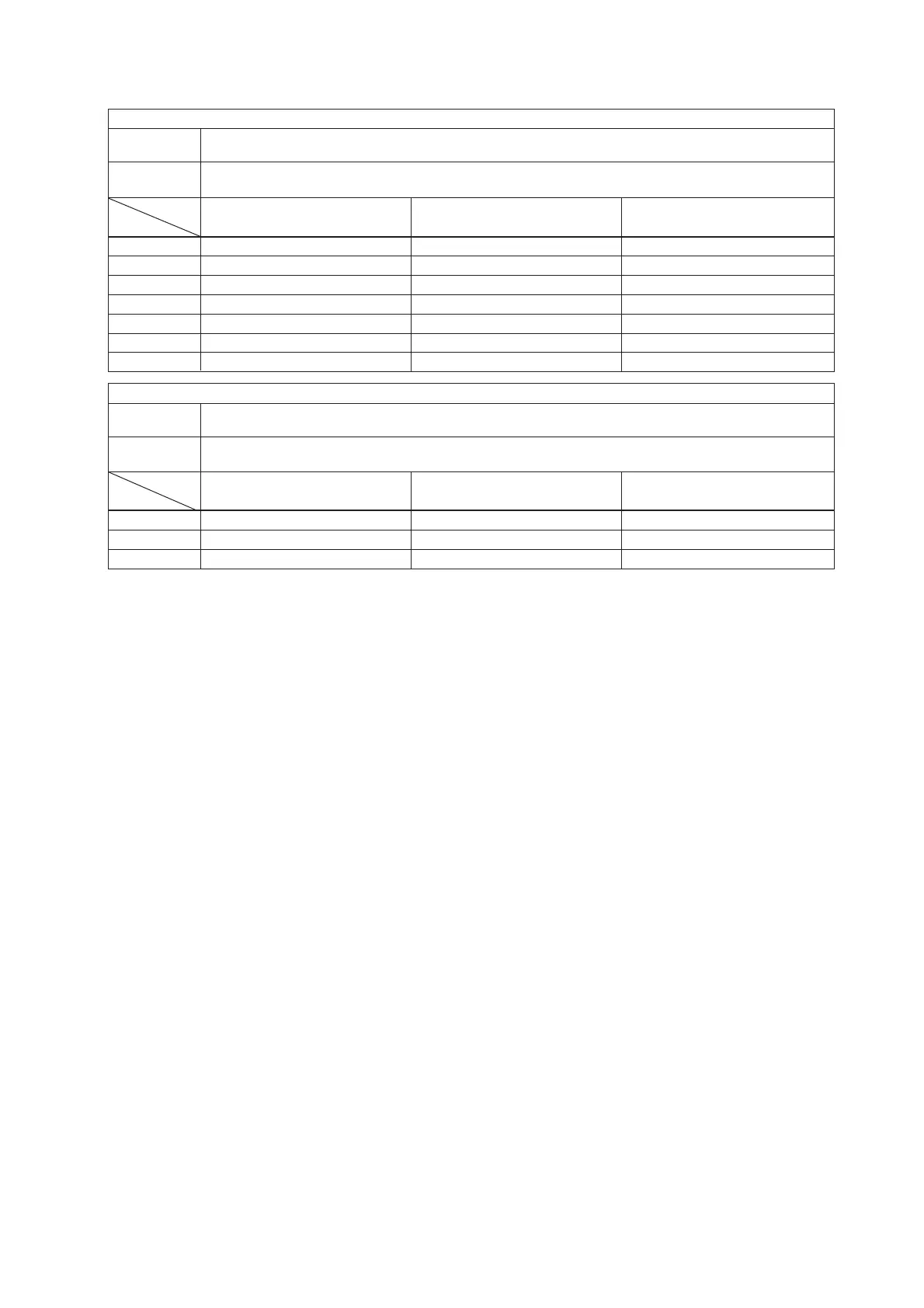

JIS 10K, ANSI Class 150, and DIN PN10 JIS 20K, ANSI Class 300, and DIN PN16 DIN PN40

Flange ratings

Size

mm (inch)

2.5 (0.1)

5 (0.2)

10 (0.4)

15 (0.5)

25 (1.0)

32 (1.25)

40 (1.5)

No gasket (standard)

PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Tightening torque values for PFA lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types

within flowtube

Gasket types

for user’s flange

Gasket types

within flowtube

Gasket types

for user’s flange

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

34.9 to 40.1 / {355.9 to 408.9} / [308.9 to 354.9]

38.8 to 44.6 / {395.6 to 454.8} / [343.4 to 394.7]

53.5 to 61.5 / {545.5 to 627.1} / [473.5 to 544.3]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

10.8 to 12.4 / {110.1 to 126.4} / [95.59 to 109.7]

35.2 to 40.1 / {358.9 to 408.9} / [311.5 to 354.9]

39.2 to 44.6 / {399.7 to 454.8} / [346.9 to 394.7]

54.2 to 61.5 / {552.7 to 627.1} / [479.7 to 544.3]

11.1 to 12.4 / {113.2 to 126.4} / [98.24 to 109.7]

11.1 to 12.4 / {113.2 to 126.4} / [98.24 to 109.7]

11.1 to 12.4 / {113.2 to 126.4} / [98.24 to 109.7]

11.1 to 12.4 / {113.2 to 126.4} / [98.24 to 109.7]

32.3 to 37.1 / {329.4 to 378.3} / [285.9 to 328.4]

40.6 to 46.7 / {414.0 to 476.2} / [359.3 to 413.3]

56.4 to 61.5 / {575.1 to 627.1} / [499.2 to 544.3]

8.1 to 13.1 / {82.6 to 133.6} / [71.7 to 115.9]

22.5 to 29.0 / {229.4 to 295.7} / [199.1 to 256.7]

40.6 to 53.8 / {414.0 to 548.6} / [359.3 to 476.2]

8.1 to 13.1 / {82.6 to 133.6} / [71.7 to 115.9]

22.7 to 29.0 / {231.5 to 295.7} / [200.9 to 256.7]

49.3 to 67.7 / {502.7 to 690.3} / [436.3 to 599.2]

7.9 to 13.1 / {80.6 to 133.6} / [69.9 to 115.9]

17.4 to 29.0 / {177.4 to 295.7} / [154.0 to 256.7]

40.6 to 67.7 / {414.0 to 690.3} / [359.3 to 599.2]

T0307.EPS

Loading...

Loading...