<3. Installation>

17

IM 01C22A01-01E

IMPORTANT

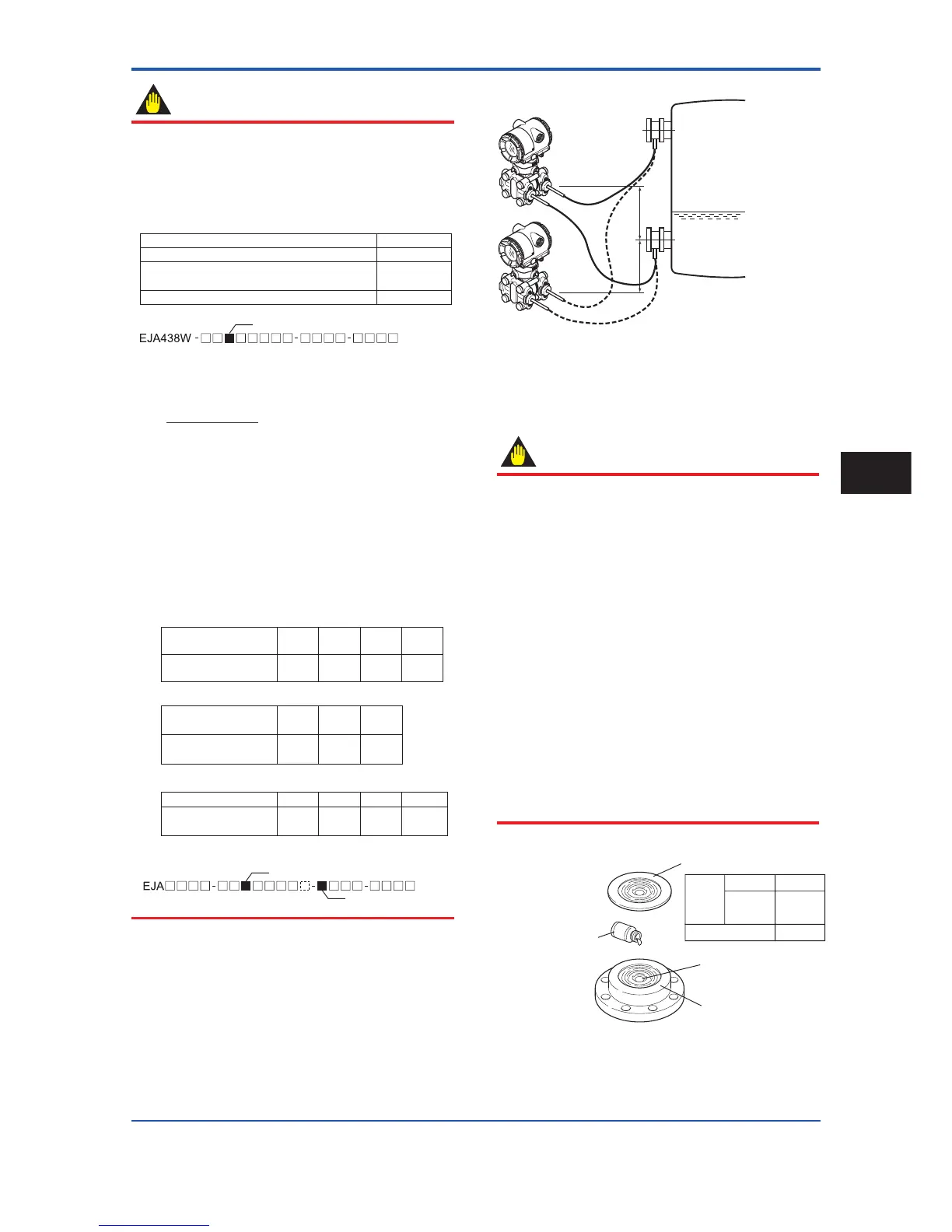

The transmitter should be installed below the high

pressure (HP) process connection to ensure a

positive head pressure of fi ll fl uid. The recommended

height between the HP process connection and the

transmitter is show in the following table. Pay special

attention to vacuum applications.

Model Height (h)

EJA118

600 mm

EJA438W Wetted parts material code S,

T, U, EJA438N

700 mm

EJA438W Wetted parts material code H 1,300 mm

Wetted parts material code

If it can not be installed below the HP process

connection with the recommended height above,

please use the equation below:

h= ×7.5×10

–3

[mm]

(P–P0)×dHg

ds

h: Vertical height between the HP process connection

and the transmitter (mm)

h≤0: Install the transmitter at least h (mm) below

the HP process connection

h>0: Install the transmitter at most h (mm) above

the HP process connection

P: Pressure in the tank (Pa abs)

P0: Minimum working pressure limit of the transmitter

(ambient temperature range: -10 to 50°C)

EJA118

Wetted parts material

code

STHU

P0: Minimum working

pressure limit

3178 3596 6074 4711

EJA438

Wetted parts material

code

ST, UH

P0: Minimum working

pressure limit

5254 6980 13019

ds: Specifi c gravity of fi ll fl uid (at 25°C)

Fill fl uid code A B C, E D

ds: Specifi c gravity

1.07 0.94 1.09

1.90 to

1.92

dHg: Specifi c gravity of the Mercury 13.6 (at 25°C)

Wetted parts material code

Fill fluid code

F0308.ai

P

h

Low

pressure side

0

High

pressure side

(+)

(–)

Figure 3.8 Example of Installation to Tank

(Caution on Installation)

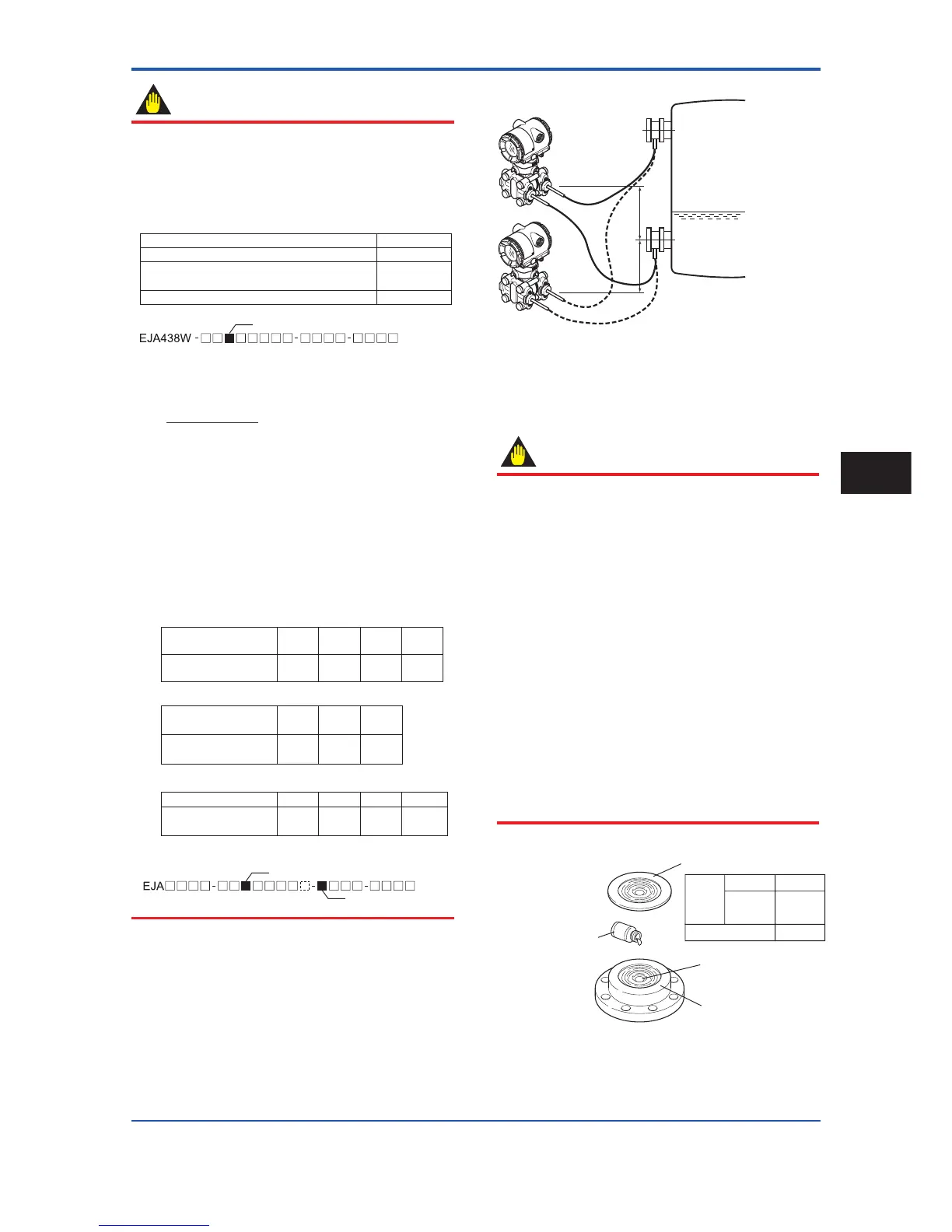

3.4 Affi xing the Tefl on Film

IMPORTANT

The FEP Teflon option includes a teflon film and

fluorinated oil. Before mounting the transmitter to the

process fl ange, affi x the tefl on fi lm as follows:

1) Position the diaphragm so that the diaphragm is in

an upward position.

2) Pour the fl uorinated oil on the diaphragm and

gasket area covering it completely and evenly. Be

careful not to scratch the diaphragm or change the

its shape.

3) Affi x the tefl on fi lm over the diaphragm and gasket

area.

4) Next, carefully inspect the cover and try to identify

any entrapped air between the diaphragm and

the tefl on fi lm. The air must be removed to ensure

accuracy. If air pockets are present, use your

fi ngers to remove the air by starting at the center of

the diaphragm and work your way out.

5) Place the gasket with the tefl on fi lm and affi x to the

process fl ange.

F0309.ai

EJA210A F9347YD

EJA118W

EJA438W

F9347YA

2B

(50A)

F9347XA3B(80A)

Teflon film

PART No.

Diaphragm

Fluorinated oil

[PART No. : F9145YN]

Gasket area

Figure 3.9 Affi xing the Tefl on Film

Installation

3

Loading...

Loading...