<5. Wiring>

25

IM 01C22A01-01E

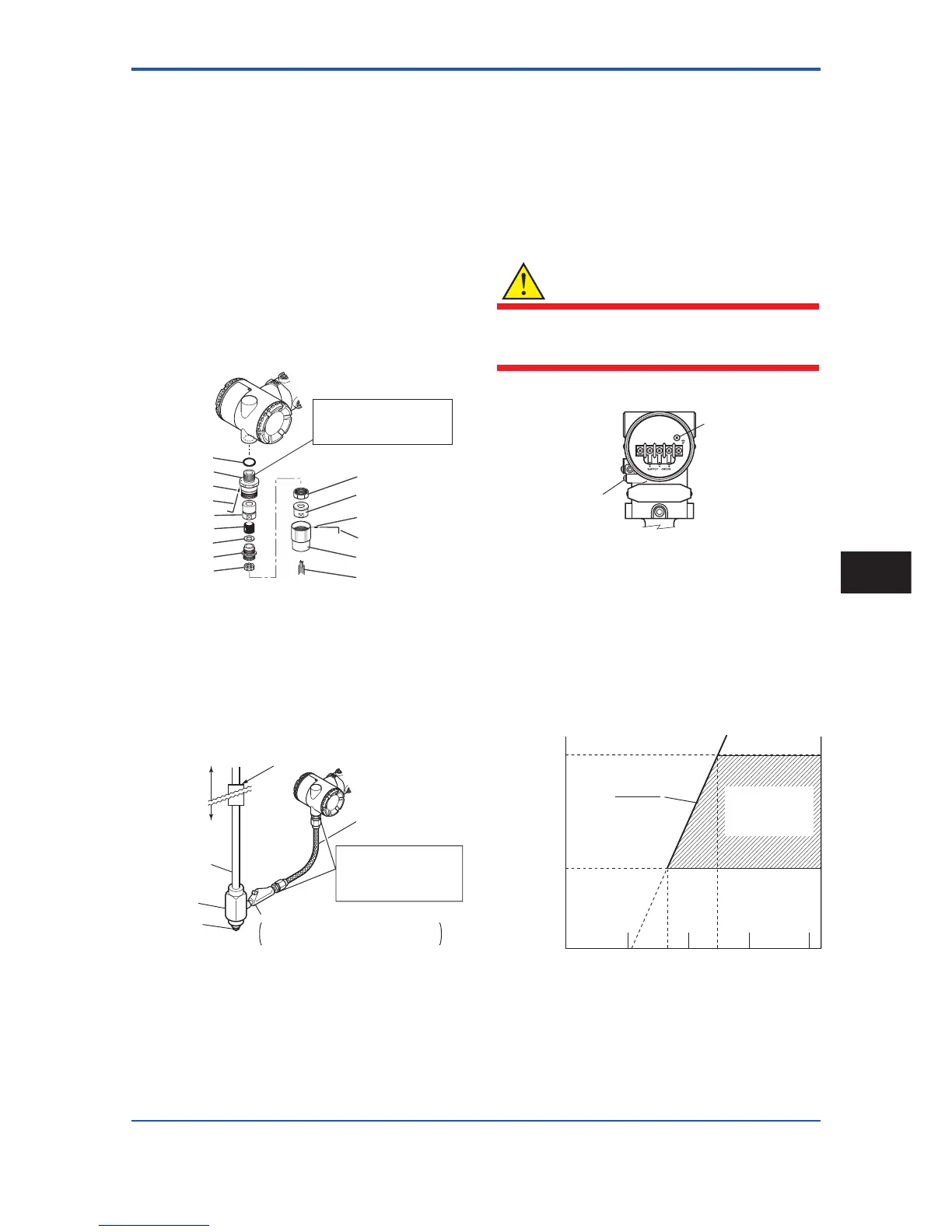

2) Insert the cable through the union cover, the union

coupling, the clamp nut, the clamp ring, the gland,

the washer, the rubber packing, and the packing

box, in that order.

3) Insert the end of the cable into the terminal box.

4) Tighten the union cover to grip the cable. When

tightening the union cover, tighten approximately

one turn past the point where the cable will no

longer move up and down.

Proper tightening is important. If it is too tight, a

circuit break in the cable may occur; if not tight

enough, the fl ameproof effectiveness will be

compromised.

5) Fasten the cable by tightening the clamp nut.

6) Tighten the lock nut on the union cover.

7) Connect the cable wires to each terminal.

O-ring

Adapter body

Lock nut

Wrench

Packing box

Rubber packing

Washer

Gland

Clamp ring

Clamp nut

Union coupling

Lock nut

Wrench

Union cover

Cable

Apply a non-hardnening

sealant to the threads for

waterproofing.

F0508.ai

Figure 5.7 Installing Flameproof Packing Adapter

Flameproof metal conduit wiring

• A seal fi tting must be installed near the terminal box

connection port for a sealed construction.

• Apply a non-hardening sealant to the threads of the

terminal box connection port, fl exible metal conduit

and seal fi tting for waterproofi ng.

F0509.EPS

Non-hazardous area

Hazardous area

Flameproof

heavy-gauge

steel conduit

Tee

Drain plug

Seal fitting

Gas sealing device

Flameproof flexible

metal conduit

Apply a non-hardening

sealant to the threads

of these fittings for

waterproofing

After wiring, impregnate the fitting

with a compound to seal tubing.

Figure 5.8 Typical Wiring Using Flameproof Metal

Conduit

5.4 Grounding

Grounding is always required for the proper operation of

transmitters. Follow the domestic electrical requirements

as regulated in each country. For a transmitter with builtin

lightning protector, grounding should satisfy ground

resistance of 10Ω or less.

Ground terminals are located on the inside and outside of

the terminal box. Either of these terminals may be used.

WARNING

For TIIS fl ameproof type and intrinsically safe,

grounding should satisfy Class D requirements

(grounding resistance, 100Ω or less).

Ground terminal

(Inside)

Ground terminal

(Outside)

Transmitter terminal box

F0610.ai

Figure 5.9 Ground Terminals

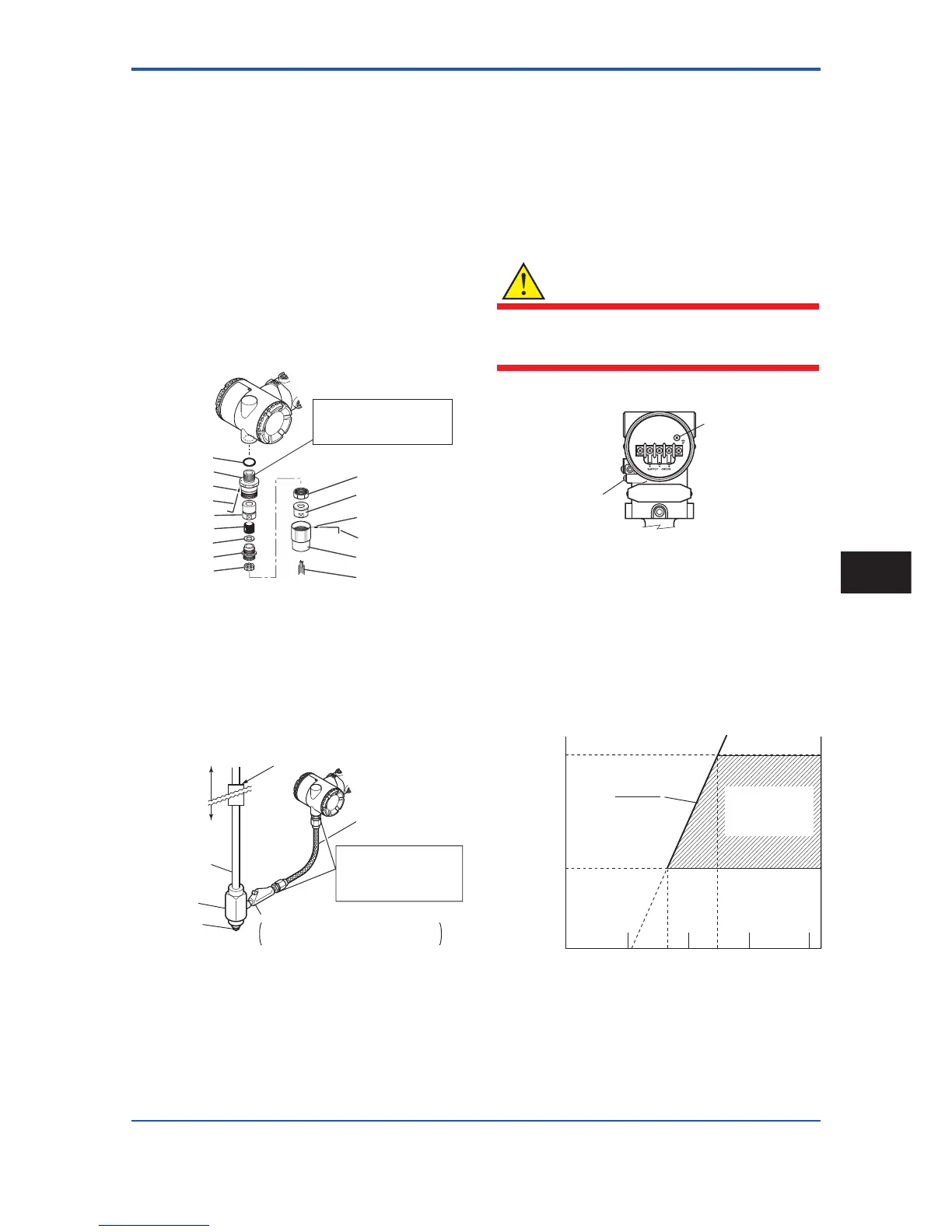

5.5 Power Supply Voltage and

Load Resistance

When confi guring the loop, make sure that the external

load resistance is within the range in the fi gure below.

(Note) In case of an intrinsically safe transmitter, external load

resistance includes safety barrier resistance.

600

250

0 10.5 16.4 24.7 42

External

load

resistance

R (Ω)

Power supply voltage E (V DC)

F0511.ai

Communication

applicable range

BRAIN and HART

R=

E–10.5

0.0236

Figure 5.10 Relationship between Power Supply

Voltage and External Load Resistance

Wiring

5

Loading...

Loading...