<4. Installing Impulse Piping>

21

IM 01C22A01-01E

(5) Condensate Pots for Steam Flow

Measurement

If the liquid in the impulse piping repeatedly condenses

or vaporizes as a result of changes in the ambient or

process temperature, this will cause a difference in the

fl uid head between the high pressure and low pressure

sides. To prevent measurement errors due to these head

differences, condensate pots are used when measuring

steam fl ow.

(6) Preventing Wind Speed Effects in Very Low

Differential Pressure Measurement

IMPORTANT

When using a differential pressure transmitter to

measure very low pressures (draft pressure), the low

pressure connection port is left open to atmospheric

pressure (the reference pressure).

Any wind around the differential pressure transmitter

will therefore cause errors in the measurement. To

prevent this, it will be necessary either to enclose the

transmitter in a box, or to connect a impulse piping to

the low pressure side and insert its end into a wind

excluding pot (cylindrical with a base plate).

(7) Preventing Freezing

If there is any risk that the process fl uid in the impulse

piping or transmitter could freeze, use a steam jacket or

heater to maintain the temperature of the fl uid.

4.2 Impulse Piping Connection

Examples

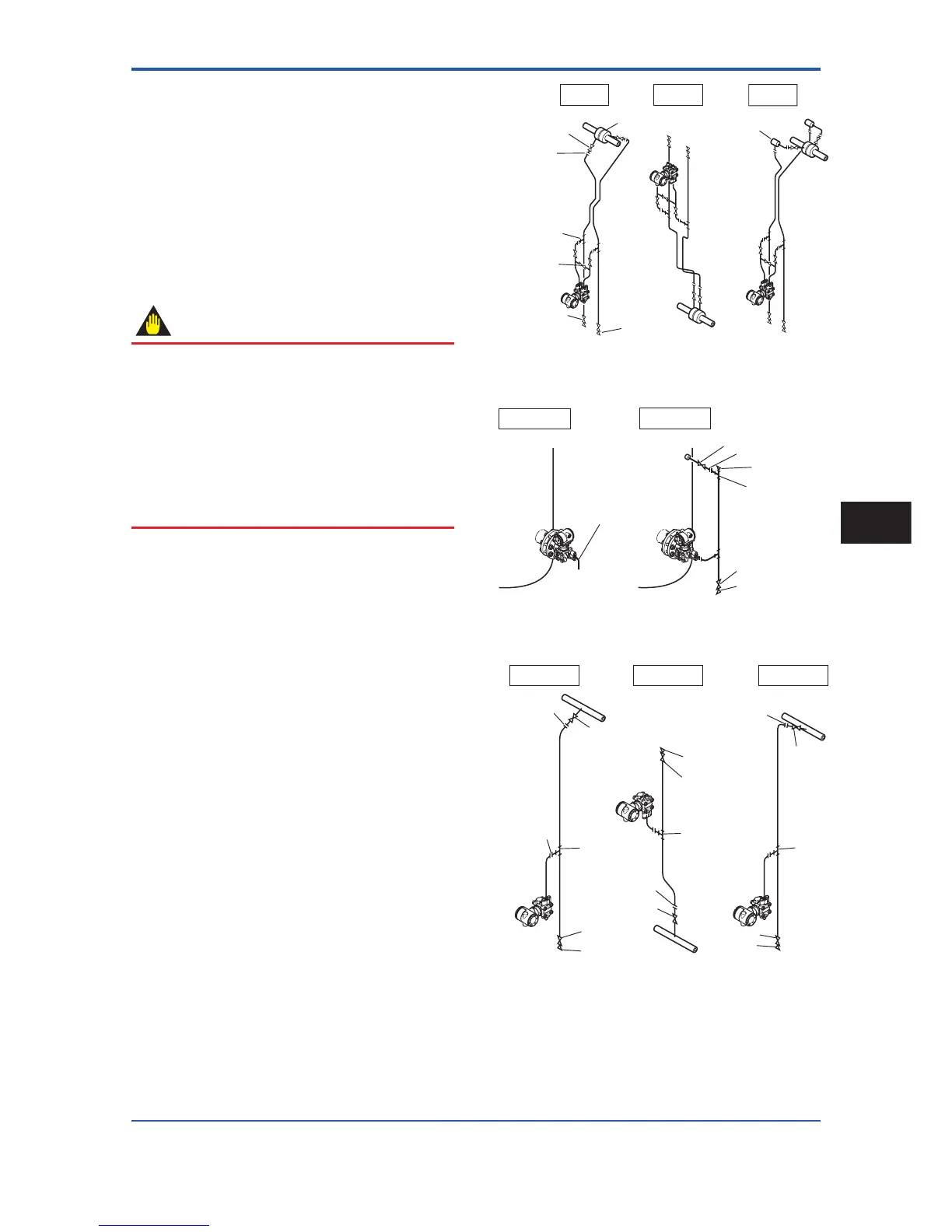

Figure 4.6, 4.7, and 4.8 shows examples of typical

impulse piping connections. Before connecting the

transmitter to the process, study the transmitter

installation location, the process piping layout, and

the characteristics of the process fl uid (corrosiveness,

toxicity, fl ammability, etc.), in order to make appropriate

changes and additions to the connection confi gurations.

Note the following points when referring to these piping

examples.

• If the impulse piping is long, bracing or supports

should be provided to prevent vibration.

• The impulse piping material used must be compatible

with the process pressure, temperature, and other

conditions.

• A variety of process pressure tap valves (main valves)

are available according to the type of connection

(fl anged, screwed, welded), construction (globe, gate,

or ball valve), temperature and pressure. Select the

type of valve most appropriate for the application.

Tee

3-valve

manifold

Drain valve

Orifice

Drain plug

Tap valve

Union

or flange

Liguid

Gas

Condensate pot

Steam

F0406.ai

Figure 4.6 Impulse Piping Connection Examples

(EJA110A)

Pipe (opened to

atmosphere at low

pressure side)

Open Tank

Closed Tank

Tap valve

Union or flange

Vent plug

Tee

Drain valve

Drain plug

F0407.ai

Figure 4.7 Impulse Piping Connection Examples

(EJA210A and EJA220A)

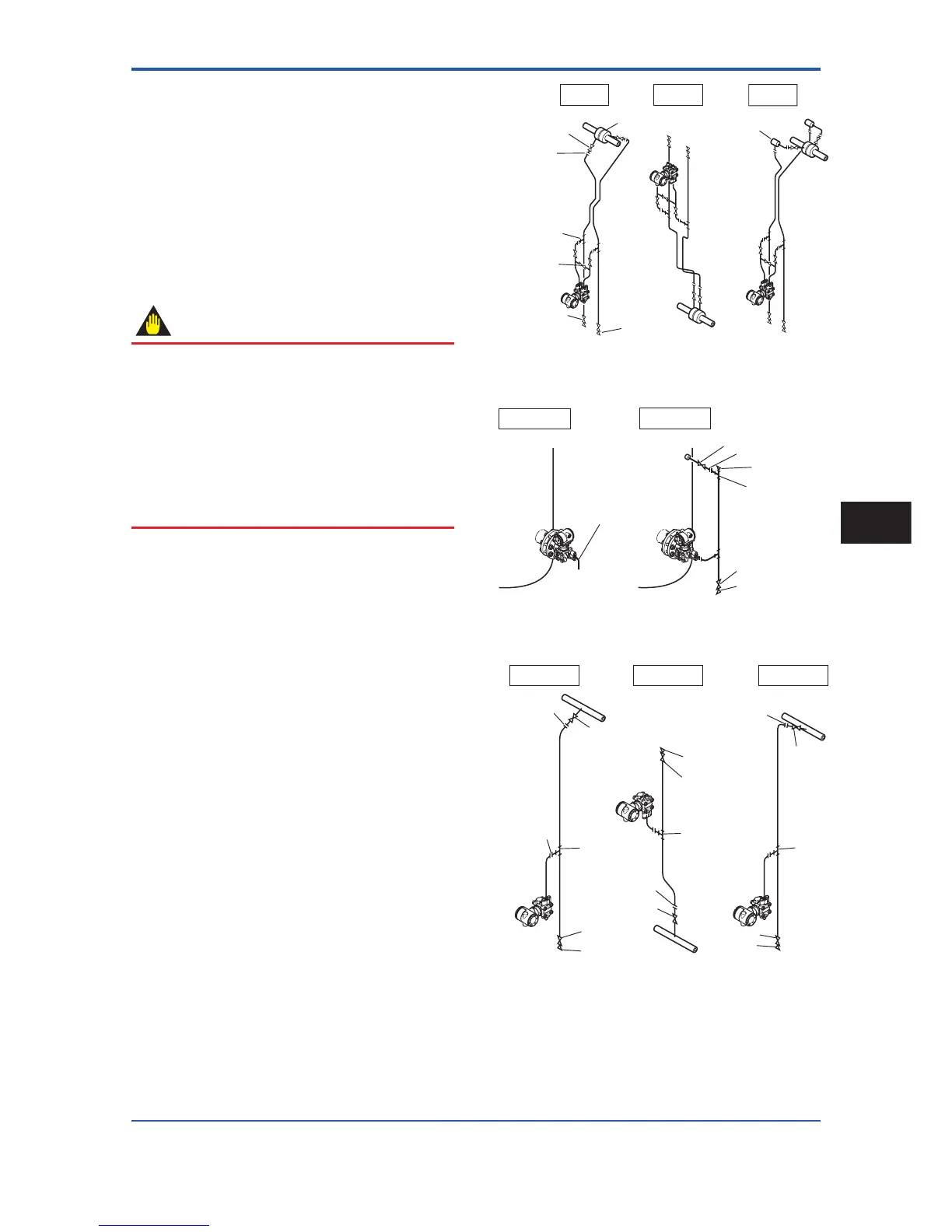

F0408.ai

Liquid

Gas Steam

Union or flange

Tee

Tee

Drain plug

Drain valve

Drain valve

Drain plug

Union or flange

Union or

flange

Union or flange

Tap valve

Tap valve

Tee

Drain valve

Drain plug

Tap valve

Figure 4.8 Impulse Piping Connection Examples

(EJA310A, EJA430A, and EJA440A)

Installing Impulse Piping

4

Loading...

Loading...