<2. Wiring and Installation>

10

IM 12A01A02-12E 9th Edition : Mar. 23, 2018-00

CAUTION

Do not tighten up four front panel screws one by one.

Eachfrontpanelscrewshouldbetightenedupintwotimesofscrewing.And,rstlythescrew

at the upper left should be screwed a bit, the next is at the lower right, third is at the upper right,

and fourth is at the lower left. The second round is the same sequence again to tighten up four

screws.

Do not use an electric screwdriver with high revolutions. If an electric screwdriver is used for

these front panel screws, the revolutions of the electric screwdriver should be less than 400 rpm.

Four screws should be tightened to the following torque; 0.8 to 0.9 N•m

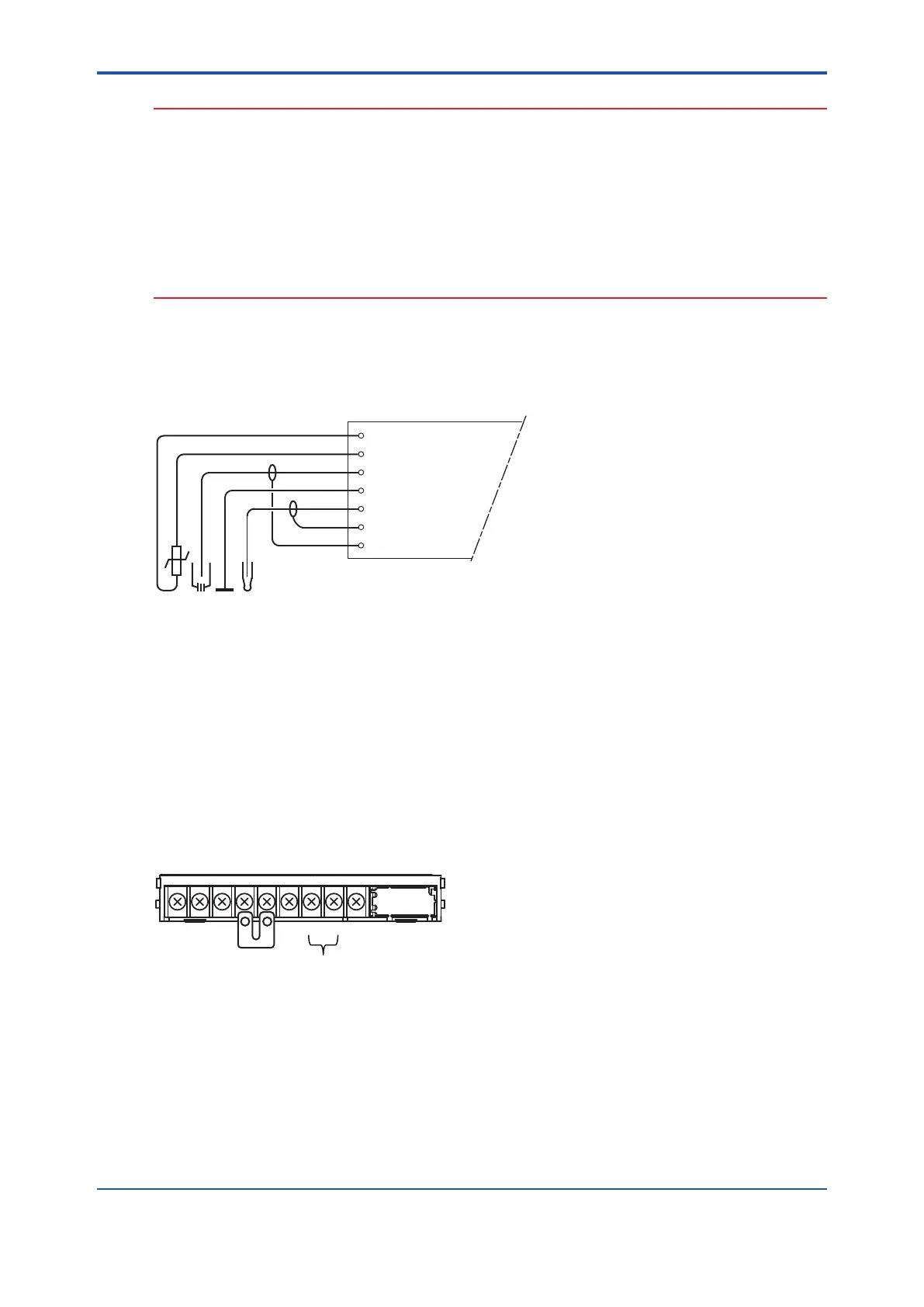

2.3.1 pH Measurement

Conventional pH sensors are connected to the module as follows:

11 Temperature

12 Temperature

13 Reference

14 Solution ground

15 Glass (measure)

16 Shield

17 Shield

FLXA202/FLXA21

REFTC PHLiquid

Earth

In addition to the wiring of the sensor, insure that a jumper for low-impedance sensor inputs is

installed. The jumpers can be found on the plastic sensor module cover and can be stored in the

lower level module wiring cover.

• pH Glass Electrode is a high impedance sensor input

• Standard reference electrodes and an ORP/REDOX electrode are low impedance sensor

inputs

• Special electrodes using 2 glass sensor (example: Pfaudler, SC24V) do not need jumpers.

Terminals15-19areidentiedasinput1(HighImpedance)andterminals13-18aredenedas

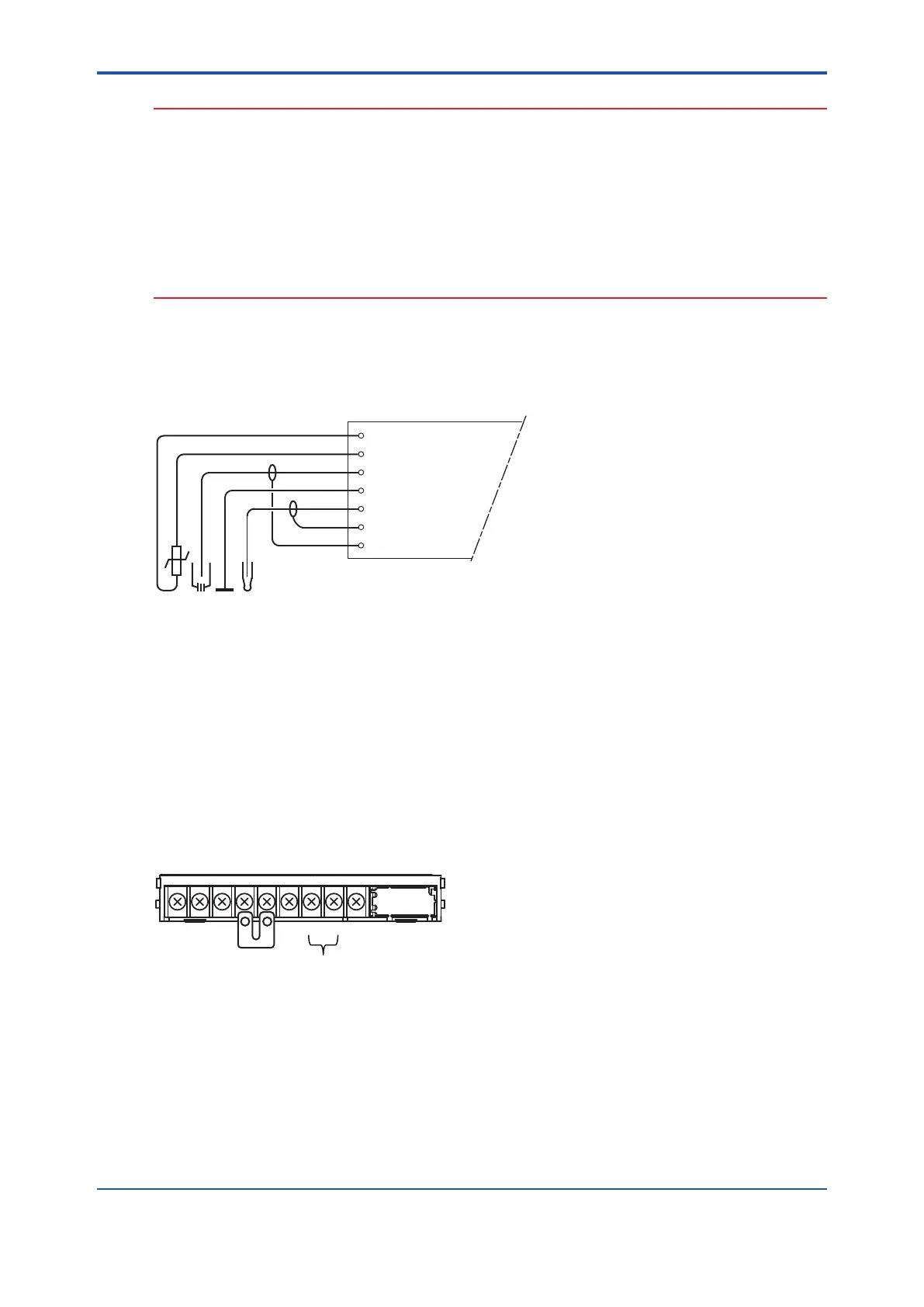

input 2 (Low Impedance). For conventional pH sensors, the jumper is placed as illustrated:

16

15191713181412

11

PH

Input 1

Input 2

Glass sensor on Input 1.

Reference sensor on Input 2.

Loading...

Loading...