Sensor installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

31 / 90

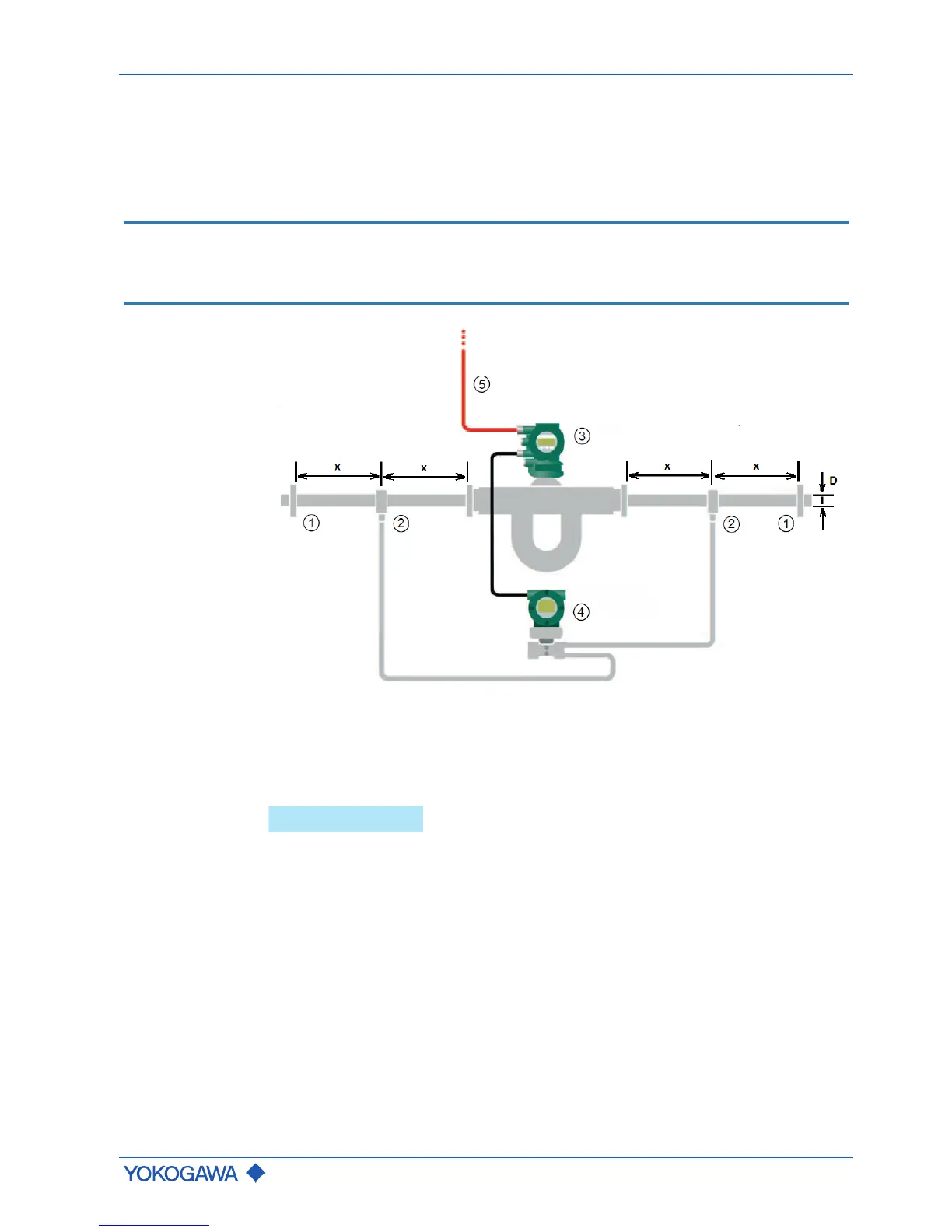

6.3.4 Installation recommendation for viscosity measurements

For the Rotamass sensor this function can only be used if it is present an external differ-

ential pressure transmitter (to order separately) measuring the pressure difference at the

flow line. The accuracy of the estimated viscosity is strongly depending on the accuracy

of the pressure transmitter and the correct position and implementation of the pressure

taps.

NOTICE

The needed pressure taps have to be placed at the flow line at approximately 4D … 5D

upstream and downstream of the Rotamass sensor. The differential pressure transmitter

is directly connected via analog input to the Rotamass transmitter (analog input function

must be available).

Fig.25: Positioning of pressure taps

① Mounting flanges ④ Differential pressure transmitter

② Pressure taps ⑤ HART communication

③ Rotamass Total Insight

x Flow line upstream or downstream of the Rotamass Total Insight sensor

D Inner diameter of process line

Loading...

Loading...