IM 05P01D31-11EN page 1/12

Contents

1. Safety Precautions

2. ModelandSufxCodes

3. How to Install

4. HardwareSpecications

5. HowtoConnectWires

6. TerminalWiringDiagrams

Introduction

ThankyouforpurchasingtheUT35A/UT32ADigitalIndicatingController.

ThisoperationguidedescribesthebasicoperationsoftheUT35A/UT32A.Theguide

shouldbeprovidedtotheenduserofthisproduct.

Be sure to read thisoperationguidebefore usingthe product in order to ensure

correct operation.

Fordetailsofeachfunction,refertotheelectronicmanual.Beforeusingtheproduct,

refertothetableofModelandSufxCodestomakesurethatthedeliveredproduct

isconsistentwiththemodelandsufxcodesyouordered.Alsomakesurethatthe

followingitemsareincludedinthepackage.

•DigitalIndicatingController(themodelyouordered) ..............................x1

• Set of Brackets ........................................................................................x1

•UnitLabel(L4502VZ) ..............................................................................x1

•TagLabel(L4502VE) ..............................................................................x1

•OperationGuide(thisdocument) ............................................................x6(A3size)

(InstallationandWiring,InitialSettings,Operations,andParameters)

l

TargetReaders

Thisguideisintendedforthefollowingpersonnel;

• Engineersresponsibleforinstallation,wiring,andmaintenanceoftheequipment.

• Personnelresponsiblefornormaldailyoperationoftheequipment.

1. Safety Precautions

Thefollowing symbolisused ontheinstrument.Itindicatesthepossibilityofinjury

to theuserordamagetotheinstrument, and signies that theuser must refer to

the user’smanualforspecial instructions. Thesamesymbol isused inthe user’s

manualonpagesthattheuserneedstoreferto,togetherwiththeterm“WARNING”

or“CAUTION.”

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and indicates precautions that should be

taken to prevent such occurrences.

Calls attention to actions or conditions that could cause injury to

the user or damage to the instrument or property and indicates pre-

cautions that should be taken to prevent such occurrences.

Theequipmentwhollyprotectedbydoubleinsulationorreinforcedinsulation.

Functionalgroundingterminals

(Donotusethisterminalasaprotectivegroundingterminal).

Note

Identiesimportantinformationrequiredtooperatetheinstrument.

n

Warning and Disclaimer

(1) YOKOGAWAmakesnowarrantiesregardingtheproductexceptthosestatedin

theWARRANTYthatisprovidedseparately.

(2) Theproductisprovidedonan"asis"basis.YOKOGAWAassumesnoliabilityto

anypersonor entityfor anyloss ordamage, director indirect,arisingfromthe

useoftheproductorfromanyunpredictabledefectoftheproduct.

n

Safety,Protection,andModicationoftheProduct

(1) Inordertoprotect thesystemcontrolled bythisproduct andtheproduct itself,

and toensuresafeoperation, observethesafety precautionsdescribed inthe

user’s manual. Useoftheinstrument in a manner notprescribed herein may

compromise the product's functions and the protection features inherent in the

device.Weassumenoliabilityforsafety,orresponsibilityfortheproduct'squality,

performanceorfunctionalityshouldusersfailtoobservetheseinstructionswhen

operatingtheproduct.

(2) Installation of protection and/or safety circuits with respect to a lightning

protector;protectiveequipmentforthesystemcontrolledbytheproductandthe

productitself;foolprooforfailsafedesignofaprocess orline usingthe system

controlledbytheproductortheproductitself;and/orthedesignandinstallation

ofotherprotectiveandsafetycircuitsaretobeappropriatelyimplementedasthe

customer deems necessary.

(3) Besuretouse thesparepartsapproved byYOKOGAWAwhenreplacing parts

orconsumables.

(4) Thisproductisnot designedormanufacturedtobe usedincriticalapplications

thatdirectlyaffect or threaten human lives. Suchapplications includenuclear

power equipment, devices using radioactivity, railway facilities, aviation

equipment, airnavigation facilities, aviation facilities,andmedical equipment.

If so used, it is the user’s responsibility to include in the system additional

equipmentanddevicesthatensurepersonnelsafety.

(5) Modicationoftheproductisstrictlyprohibited.

l

Power Supply

Ensure that the instrument’s supply voltage matches the voltage

of the power supply before turning ON the power.

l

Do Not Use in an Explosive Atmosphere

Do not operate the instrument in locations with combustible

or explosive gases or steam. Operation in such environments

constitutes an extreme safety hazard. Use of the instrument in

environments with high concentrations of corrosive gas (H

2

S,

SO

X

, etc.) for extended periods of time may cause a failure.

l

Do Not Remove Internal Unit

The internal unit should not be removed by anyone other than

YOKOGAWA's service personnel. There are dangerous high

voltage parts inside. Additionally, do not replace the fuse by

yourself.

l

Damage to the Protective Construction

Operation of the instrument in a manner not specified in the

user’s manual may damage its protective construction.

This instrument is an EMC class A product. In a domestic environ-

ment this product may cause radio interference in which case the

user needs to take adequate measures.

2. ModelandSufxCodes

n

UT35A

[Style:S1]

Model Sufxcode

Optional

sufx

code

Description

UT35A

DigitalIndicatingController

(providedwithretransmissionoutputor15VDCloop

powersupply,2DIs,and3DOs)

(Powersupply:100-240VAC)

Type 1:

Basic

control

-0 Standard type

-1 Position proportional type

-2 Heating/coolingtype

Type 2:

Functions

0 None

1 2additionalDIs,2additionalDOs

2 5additionalDIs,5additionalDOs

Type 3: Open

networks

0 None

1

RS-485communication(Max.38.4kbps,2-wire/4-wire)

2 Ethernetcommunication(withserialgatewayfunction)

3 CC-Linkcommunication

4 PROFIBUS-DPcommunication

Displaylanguage(*1)

(Note)

-1 English

-2 German

-3 French

-4 Spanish

Casecolor(Note)

0 White(Lightgray)

1 Black(Charcoalgraylight)

Fixedcode -00 Always"-00"

Optionalsufxcodes

/LP 24VDClooppowersupply(*2)

/HA Heaterbreakalarm(*3)

/DC Powersupply24VAC/DC

/CT Coating(*4)

*1: English,German,French,andSpanishcanbedisplayedastheguidedisplay.

*2: The/LPoptioncanbespecifiedinthecombinationofType2code(anyof"0"or"1")and

Type3code(anyof"0"or"1".)

*3: The/HAoptioncanbespecifiedwhentheType1codeis“-0”or“-2”.

*4: Whenthe/CToptionisspecified,theUT35Adoesnotconformtothesafetystandards(UL

andCSA)andCEmarking.

Note:Thelastdigitofthedisplaylanguagecode(-x0)hasbeenchangedintothecasecolorcode.

n

UT32A

[Style:S1]

Model Sufxcode

Optional

sufx

code

Description

UT32A

DigitalIndicatingController(providedwithretrans-

missionoutputor15VDClooppowersupply,2DIs,

and3DOs)(Powersupply:100-240VAC)

Type 1:

Basic

control

-0 Standard type

-1 Position proportional type

-2 Heating/coolingtype

Type 2:

Functions

0 None

1

RS-485communication(Max.38.4kbps,2-wire/4-

wire)

2 2additionalDIsand2additonalDOs

Type 3:

Open networks

0 None

Displaylanguage(*1)

(Note)

-1 English

-2 German

-3 French

-4 Spanish

Casecolor(Note)

0 White(Lightgray)

1 Black(Charcoalgraylight)

Fixedcode -00 Always"-00"

Optionalsufxcodes

/LP 24VDClooppowersupply(*2)

/HA Heaterbreakalarm(*3)

/DC Powersupply24VAC/DC

/CT Coating(*4)

*1: English,German,French,andSpanishcanbedisplayedastheguidedisplay.

*2: The/LPoptioncanbespecifiedinthecombinationofType1code(anyof"-0"or"-1")

andType2code(anyof"0"or"1.")Additionally,whentheType2codeis"1",theRS-485

communicationis2-wiresystem.

*3: The/HAoptioncanbespecifiedwhentheType1codeis"-0"or"-2."

*4: Whenthe/CToptionisspecified,theUT32Adoesnotconformtothesafetystandards(UL

andCSA)andCEmarking.

Note:Thelastdigitofthedisplaylanguagecode(-x0)hasbeenchangedintothecasecolorcode.

n

Accessories (sold separately)

Thefollowingisanaccessorysoldseparately.

• LL50AParameterSettingSoftware

Model Sufxcode Description

LL50A -00 ParameterSettingSoftware

• TerminalCover

ForUT35A:ModelUTAP001;ForUT32A:ModelUTAP002

• User’sManual(A4size)

Note:User’sManualcanbedownloadedfromawebsite.

•User’sManual(CD-ROM),Model:UTAP003

Note:Containsallmanuals.

3. How to Install

n

Installation Location

The instrument should be installed in indoor locations meeting the following

conditions:

• Instrumented panel

Thisinstrumentis designedtobe mounted inaninstrumentedpanel.Mountthe

instrumentinalocationwhereitsterminalswillnotinadvertentlybetouched.

• Well ventilated locations

Mounttheinstrumentinwellventilatedlocationstopreventtheinstrument’sinter-

naltemperaturefromrising.

However,makesurethattheterminalportionsarenotexposedtowind.Exposure

to wind may cause the temperature sensor accuracy to deteriorate. To mount mul-

tipleindicating controllers, see theexternaldimensions/panelcutout dimensions

which follow.

If mounting otherinstruments adjacent totheinstrument, complywith

thesepanelcutoutdimensionstoprovidesufcientclearancebetweentheinstruments.

• Locations with little mechanical vibration

Installtheinstrumentinalocationsubjecttolittlemechanicalvibration.

• Horizontal location

Mounttheinstrumenthorizontallyandensurethatitislevel,withnoinclinationto

therightorleft.

Front panel

of controller

Keep this angle

within 30°

Rear of

controller

30°

Note

If theinstrumentismovedfroma locationwith low temperature and lowhumidity

toa placewithhightemperature andhighhumidity,orifthetemperaturechanges

rapidly, condensation will result. Moreover, inthe case of thermocouple inputs,

measurementerrorswillresult.Toavoidsuchasituation,leavetheinstrumentinthe

newenvironmentunderambientconditionsformorethan1hourpriortousingit.

Donotmounttheinstrumentinthefollowinglocations:

• Outdoors

• Locations subject to direct sunlight or close to a heater

Installtheinstrumentinalocationwithstabletemperaturesthatremainclosetoan

averagetemperatureof23°C.Donotmountitinlocationssubjecttodirectsunlight

orclosetoaheater.Doingsoadverselyaffectstheinstrument.

• Locations with substantial amounts of oily fumes, steam, moisture, dust, or

corrosive gases

Thepresenceof oilyfumes, steam,moisture,dust,or corrosivegasesadversely

affectstheinstrument.Donotmounttheinstrumentinlocationssubjecttoanyof

thesesubstances.

• Areasnearelectromagneticeldgeneratingsources

Donotplacemagnetsortoolsthatgeneratemagnetismneartheinstrument.Ifthe

instrumentisusedinlocationsclosetoa strongelectromagneticeld generating

source,themagneticeldmaycausemeasurementerrors.

• Locationswherethedisplayisdifculttosee

TheinstrumentusesanLCDfor thedisplay unit,andthiscanbedifculttosee

fromextremelyobliqueangles.Mounttheinstrumentinalocationwhereitcanbe

seenasmuchaspossiblefromthefront.

• Areasclosetoammablearticles

Absolutelydonot placetheinstrumentdirectly onam-

mablesurfaces. Ifsuch acircumstanceisunavoidable

andtheinstrumentmustbeplacedclosetoaammable

item,provideashieldforitmadeof1.43mmthickplated

steel or 1.6 mm thick unplated steel with a space of at

least150mmbetweenitandtheinstrumentonthetop,

bottom,andsides.

• Areas subject to being splashed with water

Be sure to turn OFF the power supply to the controller before in-

stalling it on the panel to avoid an electric shock.

150 mm150 mm

150 mm

150 mm

150 mm150 mm

150 mm

150 mm

Operation

Guide

IM 05P01D31-11EN

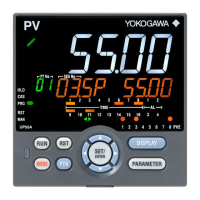

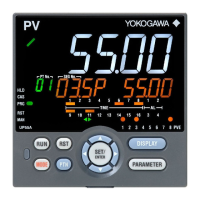

UT35A/UT32A

Digital Indicating Controllers

Operation Guide

This operation guide describes installation, wiring, and other tasks required to make the

controller ready for operation.

2nd Edition : Jun. 2010

Installation and Wiring

n

Waste Electrical and Electronic Equipment (WEEE),

Directive 2002/96/EC

ThisisanexplanationofhowtodisposeofthisproductbasedonWasteElectrical

andElectronicEquipment(WEEE),Directive2002/96/EC.Thisdirectiveisonlyvalid

intheEU.

Marking

This product complies with the WEEE Directive (2002/96/EC)

markingrequirement.

This marking indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive Annex 1, this

product is classified as a “Monitoring and Control instrumentation” product.

Donot disposeindomestichouseholdwaste. Whendisposing productsintheEU,

contactyourlocalYokogawaEuropeB.V.ofce.

www.yokogawa.com/ns

YOKOGAWA ELECTRIC CORPORATION

Network Solutions Business Division

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 JAPAN

YOKOGAWA CORPORATION OF AMERICA

Head office and for product sales

2 Dart Road, Newnan, Georgia 30265, USA

YOKOGAWA EUROPE B.V.

Headquarters

Euroweg 2, 3825 HD Amersfoort, THE NETHERLANDS

All Rights Reserved, Copyright © 2010 Yokogawa Electric Corporation