31

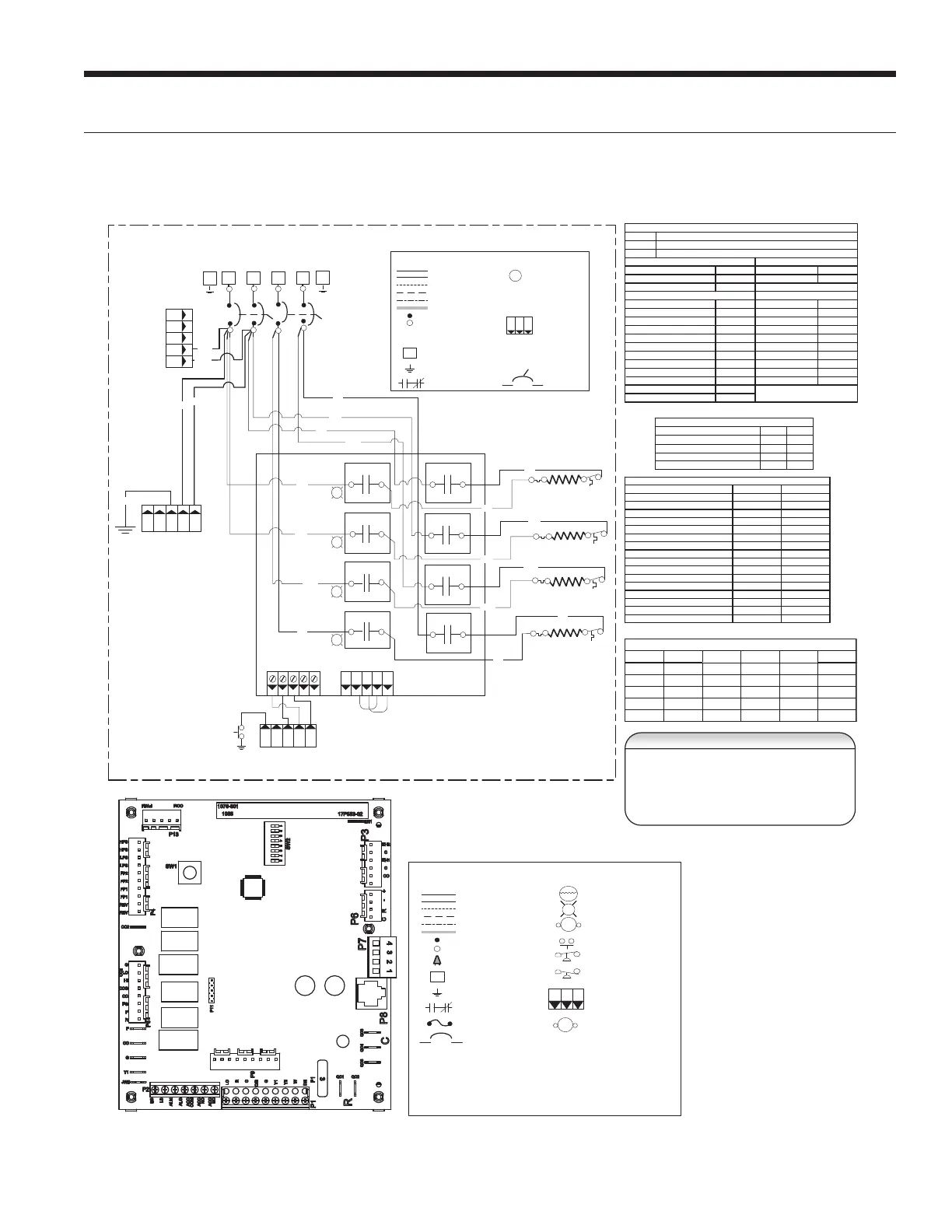

Wiring Schematics cont.

Aurora BASE with 5 Speed ECM and IntelliStart

2

3

P9

5

4

1

L2 L1 L2 L1

Green

P112 3 4 51

Violet

Blue

Brown

Orange

HE1

TS 1

HE3

TS3

HE2

TS2

HE4

TS4

Connects to variable

speed E CM motor only

60 AMP

BR K1

60 AMP

BR K2

G

G

K1

K2

K3

K4

NO

NO

NO

NO

EA Series

PCB

P2

412

3

C

G

G

G

G

K5

NO

K6

NO

K7

NO

K8

NO

Gray

Yellow

Gray

Yellow

Black

Pink

Black

Pink

Pink

Pink

Gray

Black

Yellow

Gray

Black

Yellow

412

3

C

P1

COM

COM

COM

COM

COM

COM

COM

COM

Aux heat staging

FB1

FB2

FB3

FB4

P3 on Aurora ABC Board

P3

EH2CEH1

C

CO

Light emitting diode - Green

Polarized connector

Factory Low volt age wi ri ng

Factory Line voltage wiring

Fi eld l ow voltage wiring

Fi eld l ine volt age wi ring

Optional block

DC Voltage PCB traces

Internal junction

Qui ck c onnect terminal

Thermal Limi t Switch

Fi eld wi re lug

Ground

HE -

PB -

Heater element

Power block

Legend

N.O., N.C.

G

L1

Breaker

1 2 3

P

TS

Electric Heat RelayK*

Fused BackupFB

2 - Use manufact urer’s part number 19P592-01 (jumper

bar assem bly) when si ngle sourc e power is required.

1 - Use copper o r aluminum conductors.

3 – Jumpers wire s are Factory Installed, and are

required for a uxi liary heat operat ion.

4 – Low vol tage wiring CLASS 2.

NOTE 3

With optional EA Series 20kW Auxiliary Electric Heat Shown

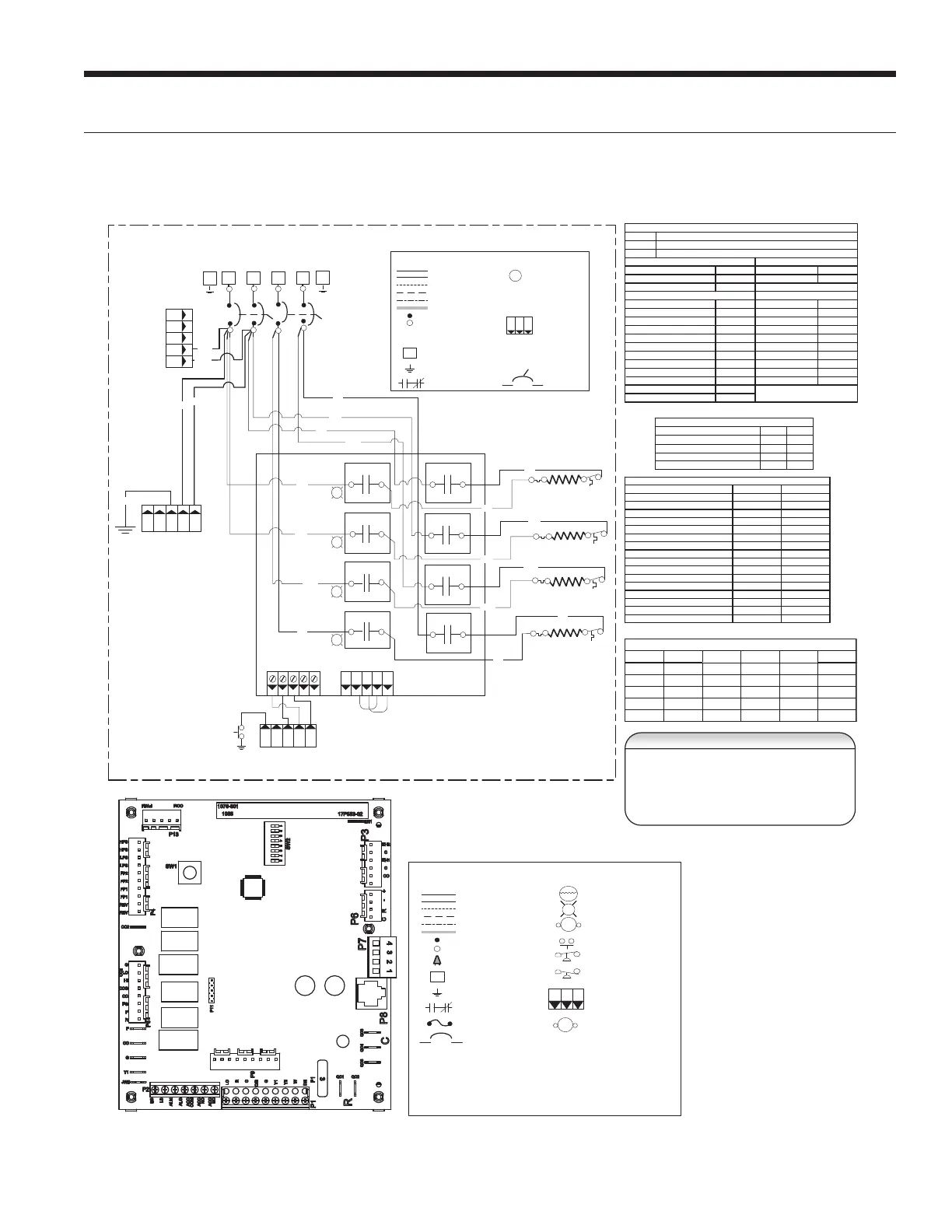

AURORA BASE

CONTROL™

Thermistor

Light emitting diode - Green

Relay coil

Switch - Condensate overflow

Switch - High pressure

Switch - Low pressure

Polarized connector

Factory Low voltage wi ring

Factory Line voltage wiring

Fi eld l ow voltage wiring

Fi eld l ine volt age wi ring

Optional block

DC Voltage PCB traces

Junction

Qui ck c onnect terminal

Wire nut

Fi eld wi re lug

Ground

Fus e

CC -

CO -

F1 -

FP1 -

HPS -

LPS -

PB1, PB2 -

RV -

SW1 -

SW2 -

TS -

Compres sor Cont actor

Condensate overflow sensor

Fus e

Water Coil Limit Sensor

High pressure switch

Low pressure switch

Power blocks

Reversi ng Valve coil

TEST MODE ABC Board

DIP package 8 position AB C Board

Thermal limit switch

Legend

Relay Con tacts-

N.O., N.C.

G

T

132

P

L1

HWL -

Hot water limit sensor

CS - Com pressor Solenoi d

Breaker

208/240V Electric Heat Relay coil

E lec tri c H ea t Co n tac tor

HE - Heater element

ER1 t o ER4 - A ux heat stage relays

EHC -

EHC

Notes

1 - Switc h blue a nd r ed wir es for 208V oper ation.

2 - The blk/wh and gray/wh wires are removed when Aux He at is installed

3 - Refer to units X13 MOTOR LOW VOLTAGE CONNECTION table for factory settings.

4 - Wires p rovided for Auxiliary Heat low voltage control. When connected the Auxiliary Heat

powers blower and controls. Wires are secured at blower.

5 - Field installed SPST relay required for dual fuel instal lation.

6 – All low voltage wi ri

ng CLAS S 2

7 – Use c opper o r aluminum conductors

Aur o ra L ED Fl as h Codes

Status LED (LED3, Green)

Status LE D (LED1, Green)

Conf iguration LED (LE D2, Yellow)

Fault LED (LED3, Red)

Random Start Delay (Altern atin g Co lo rs)

Fas t Fl ash

Fas t Fl ash

Fas t Fl ash

1 sec ond on and 1 s econd off

100 milliseconds on and 100 m illiseconds of f

100 milliseconds on and 400 milliseconds of f wit h a 2 second pause before repe ating

Slow Flash

Fast Flash

Flash Code

Normal Mode

Cont rol is Non-Functional

Test Mode

Lockout Active

Dehumidification Mode

Fut ure U se

Fut ure U se

Load Shed

ESD

OF F

ON

Slow Flash

Fas t Fl ash

Flash Code 2

Flash Code 3

Flash Code 6

Flash Code 4

Flash Code 5

Future Use Fl ash Code 7

Configuration LED (LED2, Yellow)

No Software Overide

OF F

DIP Switch Overide Slow Flash

Fau lt LED (LED1, Red)

Normal Mode

Input Fault Lockout

High Pressure Lockout

Low Pressure Lockout

Fut ure U se

Freeze Detection – FP1

Reserved

Condensate Overflow Lockout

Over/Under Voltage Shut down

Fut ure U se

Fut ure U se

FP1 Sensor Error

Flash Code 1

OF F

Flash Code 2

Flash Code 3

Flash Code 4

Flash Code 5

Flash Code 8

Flash Code 6

Flash Code 7

Flash Code 9

Flash Code 10

Flash Code 11

Event

Normal Mode Test Mode

Random Start Delay

Compress or On Delay

Compressor Minimum On Time

Compressor S hort Cycl e Delay

Blower Of f Delay

Fault Recognition Delay – High Pressure

Start-Up Bypass – Low Pressure

Fault Recognition Delay – Low Pressure

Start-Up Bypass – Low Water Coil Limit

Fault Recogn ition Delay – Low Water Coil Limit

Fault Recogn ition Delay – Condensate Overflow

Thermos tat Call Rec ognit ion Tim e

Comfort Alert Recog nition Time

Auxi liary Heat Stagi ng Delay

Emergency Heat S tagi ng Dela y

Water Valve S low Open Delay

Less than 1 sec ond

5 to 80 seconds 1 second

5 seconds < 1 second

30 seconds 2 seconds

Less than 1 second

2 minutes 5 seconds

4 minutes 15 seconds

2 minutes

2 minutes

30 seconds

30 seconds 30 seconds

30 seconds

30 seconds

30 seconds

30 seconds

30 seconds

2 seconds 2 seconds

90 seconds 90 seconds

90 seconds 90 seconds

5 minutes

2 minutes

20 seconds

7.5 seconds

Aurora T imi ng Events

DESCRIPTION SW2-4 SW2-5

Cycle with Blower ON ON

Cycle with Compressor OFF OFF

Water Valve Slow Opening ON OFF

Cycle with Comm. T-stat Hum Cmd OFF ON

ABC SW2 Accessory Relay

Model TAP-1 TAP-2 TAP-3 TAP-4 TAP-5

024 BLUE R ED T AN GRAY

036 BLUE R ED T AN GRAY

048 BLUE R ED T AN GRAY

060 BLUE R ED T AN GRAY

072 BLUE RED TAN GRAY

5 SPEED ECM MOTOR LOW VOLTAGE CONNECTIONS

LX SERIES INSTALLATION MANUAL

Loading...

Loading...