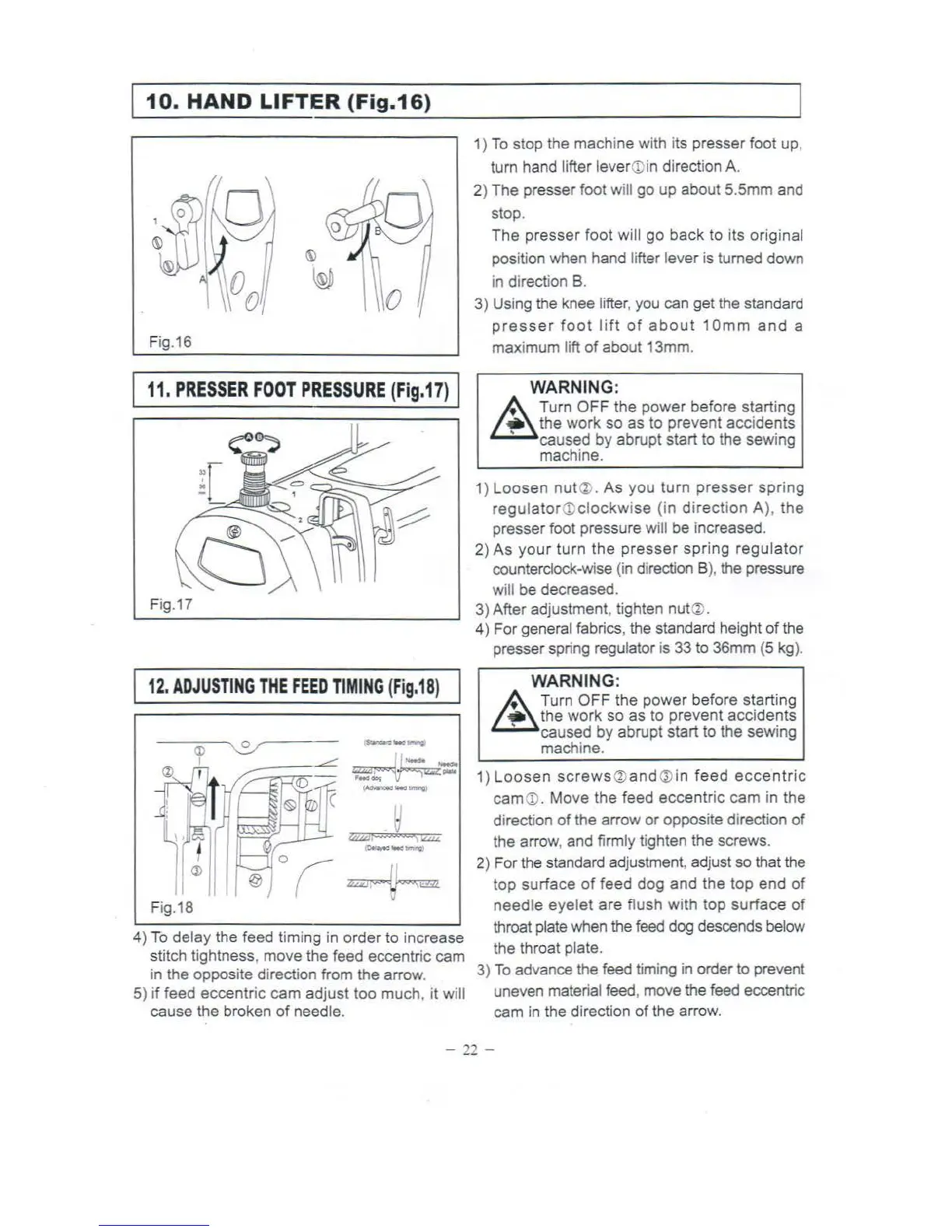

10.

HAND

LIFTER

(Fig.16)

Fig.16

1

11.

PRESSER

FOOT

PRESSURE

(Fig.17)

I

Fig.17

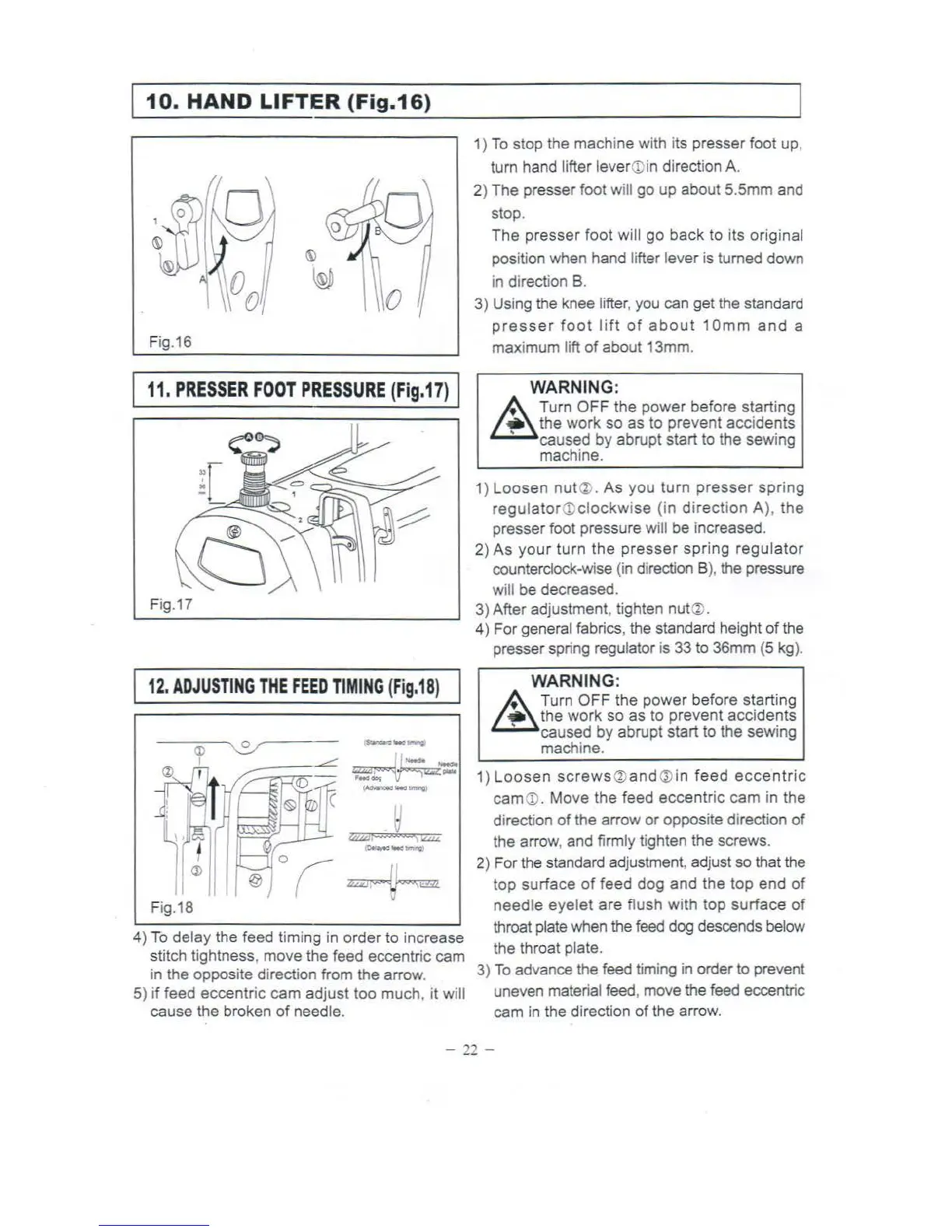

12.

ADJUSTING

THE

FEED

TIMING

(Fi

g.18

)

Fig.18

4)

To

delay the feed timing

in

order to increase

stitch tightness, move the feed eccentric cam

in the opposite direction from the arrow.

5)

if

feed eccentric cam adjust too much, it will

cause the broken

of

needle.

1)

To

stop the machine with its presser foot up,

turn hand

lifter lever

<D

in direction

A.

2) The presser foot will

go

up about 5.5mm and

stop.

The presser foot

will

go

back to its original

position when hand lifter lever

is

turned down

in

direction

B.

3) Using the knee lifter,

you

can get the standard

presser

foot

lift

of

about

1 Omm

and

a

maximum

lift

of

about 13mm.

WARNING:

A Turn OFF the power before starting

~

the

work

so

as to prevent accidents

caused by abrupt start to the sewing

machine.

1)

Loosen

nut

Q)

.

As

you turn

presser

spring

regulator

<D

clockwise

(in

direction

A)

,

the

presser foot pressure will

be

increased.

2)

As

your turn the

presser

spring regula

tor

counterclock-wise

(in

direction B

),

the pressure

will be decreased.

3) After adjustment, tighten

nut@.

4) For general fabrics, the standard height

of

the

presser spring regulator

is

33 to 36mm (5 kg).

WARNING:

A Turn OFF the power before starting

~

the

work so as to prevent accidents

caused

by

abrupt start to the sewing

machine.

1)

Loosen

screws

a>

and

O)

in

feed

eccentric

cam

<D

. Move the feed eccentric cam in the

direction

of

the arrow or opposite direction

of

the arrow, and firmly tighten the screws.

2)

For the standard adjustment, adjust so that the

top surface

of

feed dog and the top end

of

needle eyelet are flush

with

top surface

of

throat plate when the feed dog descends below

the throat plate.

3)

To

advance the feed timing in order to prevent

uneven material feed, move the feed eccentric

cam

in

the direction of the arrow.

-

22-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...