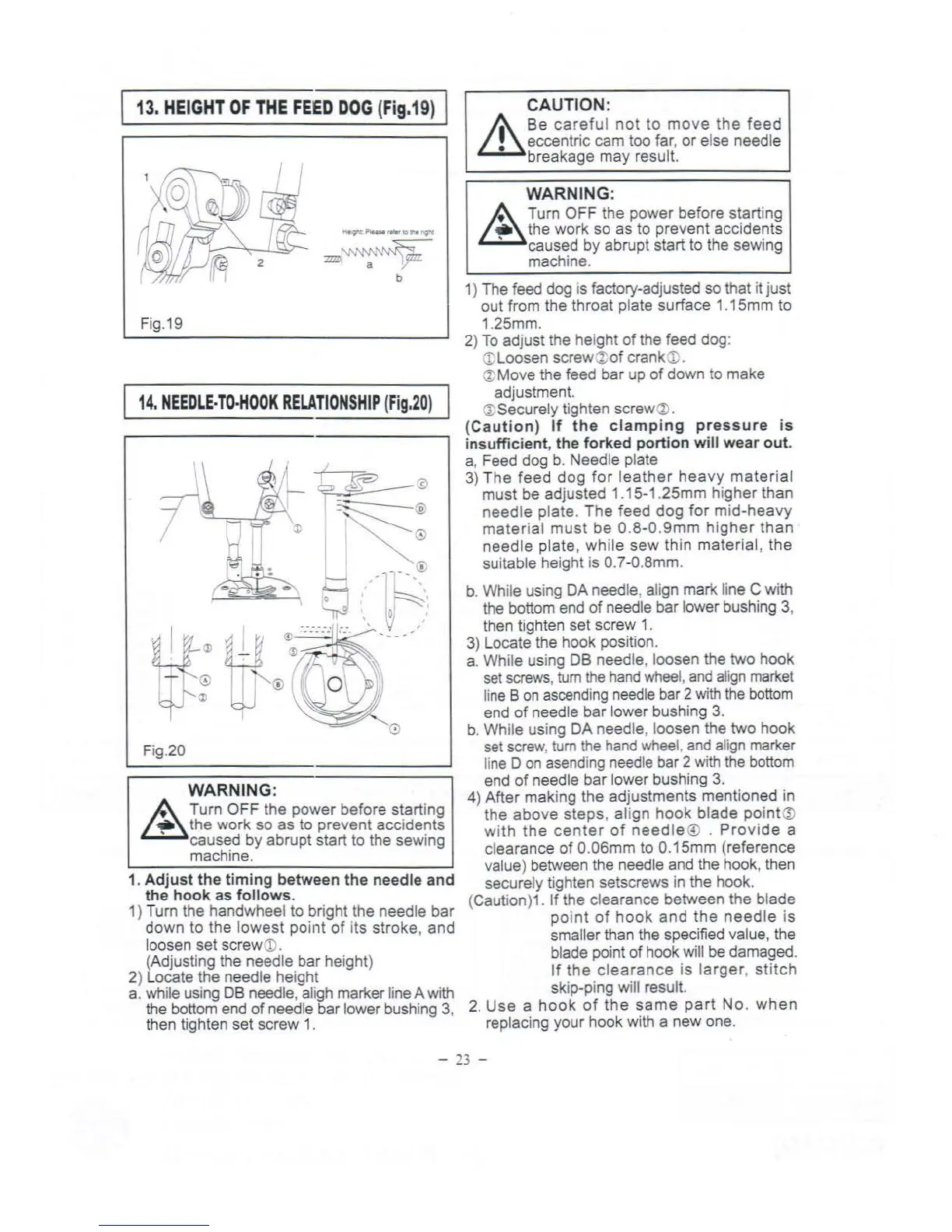

13

.

HEIGHT

OF

THE

FEED

DOG

(

Fig.

19)

Fig.19

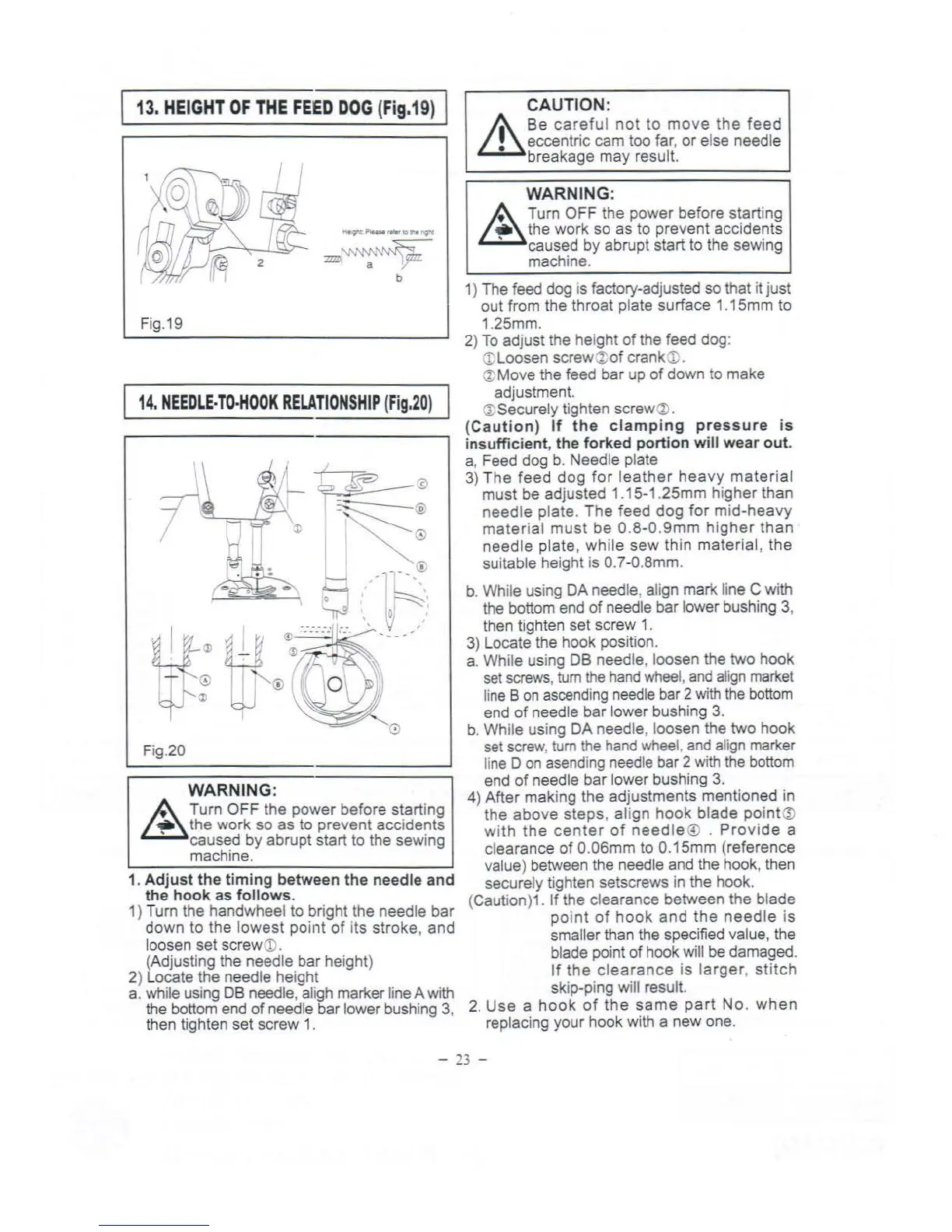

14

.

NEEDLE-TO

-

HOOK

RELATIONSHIP

(

Fig

.

20

)

Fig.20

WARNING:

I

~

@

=s_---

'D'

-

"""

~

.;>

G

I I

-- - ®

....__.

, I -.

~

,'

~

'.

:

~

:

0 I

' '

·.·.

-

_-_

-_.

t.·. ' ; ,

...

-

..

-

A Turn OFF the power before starting

~

the

work

so

as to prevent accidents

caused by abrupt start to the sewing

machine.

1.

Adjust

the

timing

between

the

needle and

the

hook

as

follows

.

1) Tum the handwheel to bright the needle bar

down

to

the lowest point

of

its stroke, and

loosen set screw

CD

.

(Adjusting the needle bar height)

2) Locate the needle

he

i

gh~

. .

a. whi

le

using DB needle, ahgh

marl<er

hne

A

w1th

the bottom end of needle bar lower bushing 3,

then tighten set screw

1.

CAUTION:

& Be

carefu

l

not

to

move

t

he

feed

eccentric cam too far,

or

else needle

breakage may result.

WARNING:

~

Turn

OFF the power before starting

the work so as to prevent accidents

caused by abrupt start to the sewing

machine.

1) The feed dog is factory-adjusted so that it just

out from the throat plate surface 1 .15mm to

1.25mm.

2)

To

adjust the height

of

the feed dog:

CD

Loosen screw@

of

crank

eD

.

® Move

the feed bar up

of

down to make

adjustment.

~

Securely

tighten screw

(%)

.

(C

autio

n)

If

the

clamp

i

ng

pressure

is

i

nsufficient

,

the

forked

portio

n

will

wear

out

a Feed dog

b.

Needle plate

3)

The

feed dog

for

l

eather

heav~

material

must be adjusted

1.

15-1 .25mm h1gher than

needle plate.

The

feed dog

for

mi

d-heavy

mater

ial

must

be

0.8-0.

9mm

higher

than

needle

plate,

while

sew

thin material,

the

suitable height is

0.

7 -0.8mm.

b. Wh

il

e usi

ng

DA needle. a

li

gn

marl<

line C with

the bottom end

of

needle bar lower bushing 3,

then tighten set screw 1 .

3)

Locate the hook position.

a. While using DB needle, loosen the two hook

set

screws

,

tum

the

hand

whee

l,

and

a

li

gn

market

li

ne

B

on

ascending

needle

bar

2

with

the

bottom

end

of

needle bar lower bushing 3.

b. Wh

il

e using DA needle, loosen the two hook

set

screw,

tum

the hand

whee

l,

and

a

li

gn

marker

li

ne

D

on

asend

i

ng

needle bar 2

with

the

bottom

end

of

needle

ba

r lower bushing

3.

4) After making the adjustments mentioned

in

the above

steps

, align

hook

blade

po

int@

with

the

center

of

need

le ® .

Provide

a

clearance

of

0.06mm to 0.15mm (reference

value) between the needle and the hook, then

securely tighten setscrews in the hook.

(Cauti

on

)

1.

If the clearance between the

b

l

a~e

point

of

hook

and

the

needle

IS

smaller than the specified value, the

blade point of hook will

be

damaged.

If

the

clearance

is

l

arger

,

stitch

skip-ping will result.

2.

Use

a

hook

of

the

same

part

No.

when

replacing your hook with a new one.

-

23

-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...