I

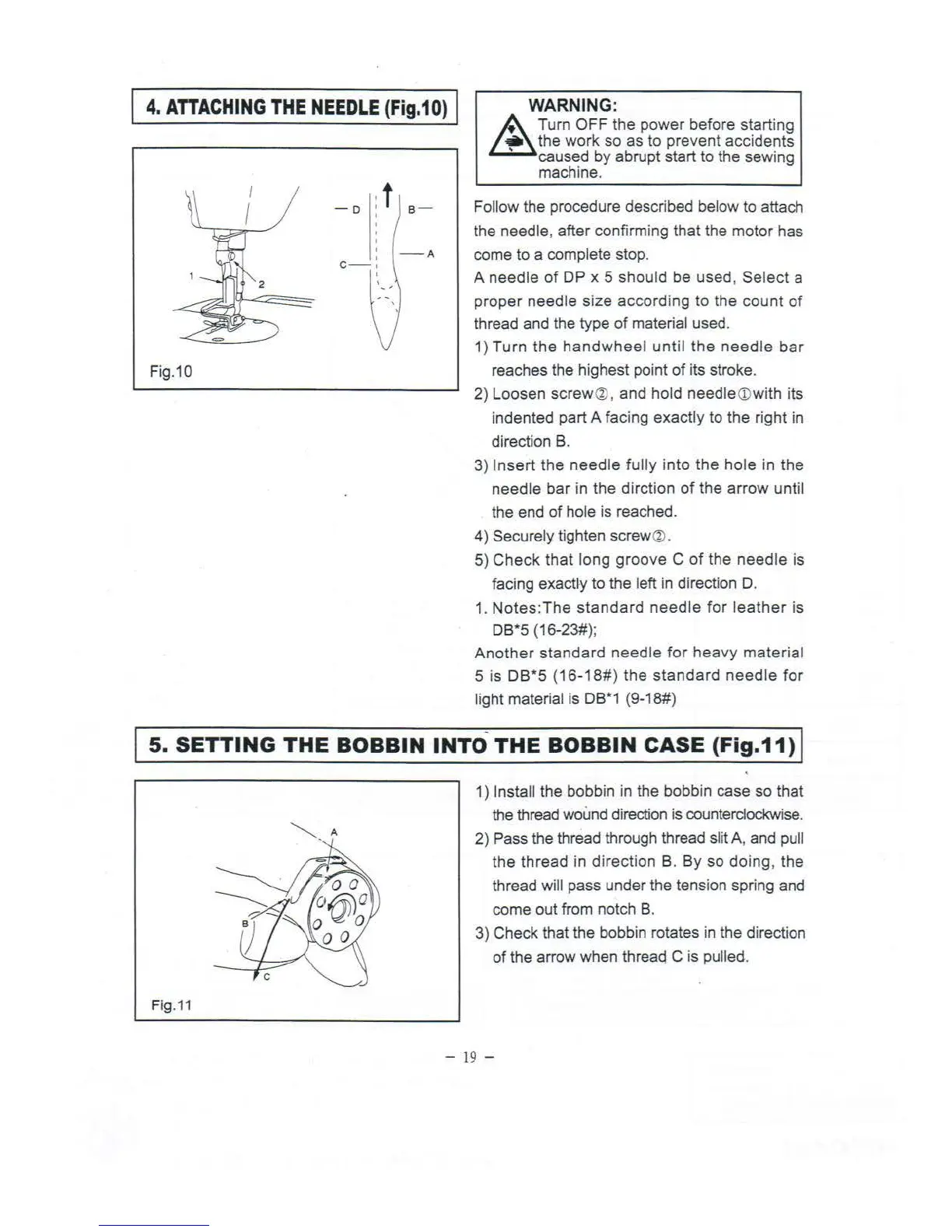

4.

ATTACHING

THE

NEEDLE

(Fig.10)

I

Fig.10

-o

I

c-

,

I

I

WARNING:

A Turn

OFF

the

power

before starting

L.:1!::::::.

the

work

so as

to

prevent

accidents

' caused

by

abrupt start to the sewing

machine.

Follow the procedure described below to attach

the needle,

after

confirming that the

motor

has

come to a complete stop.

A

needle

of

DP

x 5

should

be used,

Se

l

ect

a

proper

needle

size

according

to the

count

of

thread and the type

of

material used.

1)

Turn

the

handwheel

until

the

needle

bar

reaches the highest point

of

its stroke.

2)

Loosen

screw

@,

and hold

needle

<D

with its

indented part A facing

exactly

to the right in

direction

B.

3)

Insert

the

needle

fully

into

the

hole

in

the

needle

bar

in

the

dirction

of

the

arrow

until

the end

of

hole is reached.

4)

Securely tighten screw

®.

5)

Check

that

long

groove

C

of

the

needle

is

facing exactly

to

the left in direction D.

1.

Notes:The

standard

needle

for

leather

is

DB*S {16-23#);

Another

standard

needle

for

heavy

material

5

is

DB*5

{16-18#)

the

standard

needle

for

light material is DB*1 (9-18#)

I

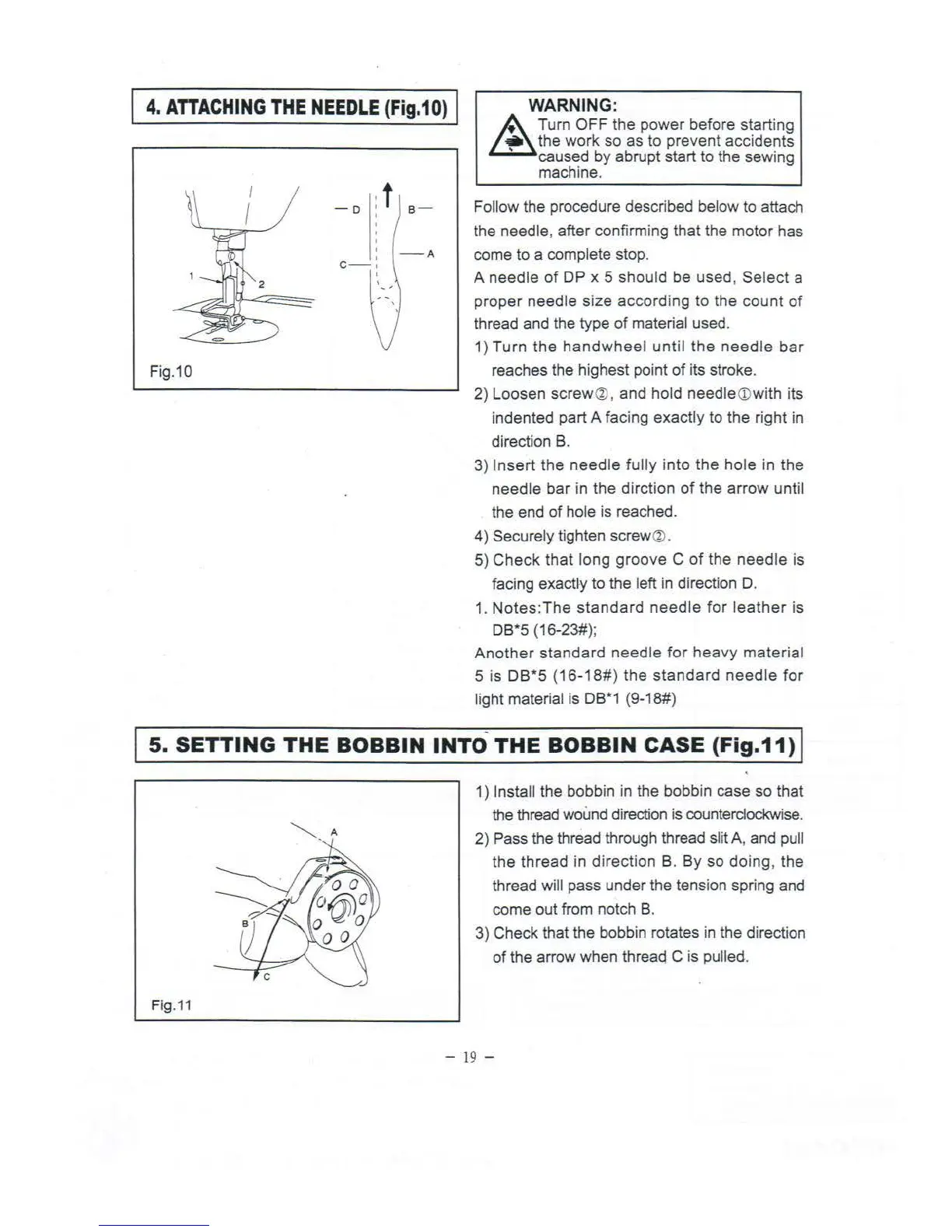

5.

SETTING

THE

BOBBIN

INTO

-

THE

BOBBIN

CASE

(Fig.11)

I

~-

A

Fig.

11

1) Install the bobbin in the bobbin case

so

that

the thread wound direction is counterclockwise.

2) Pass the thread through thread

sl

it

A, and pull

the

thread

in

direction

B.

By

so

doing

, the

thread

will pass under the tension spring and

come

out

from notch

B.

3) Check that the bobbin rotates in the direction

of

the arrow when thread C is pulled.

- 1

9-

Loading...

Loading...