22

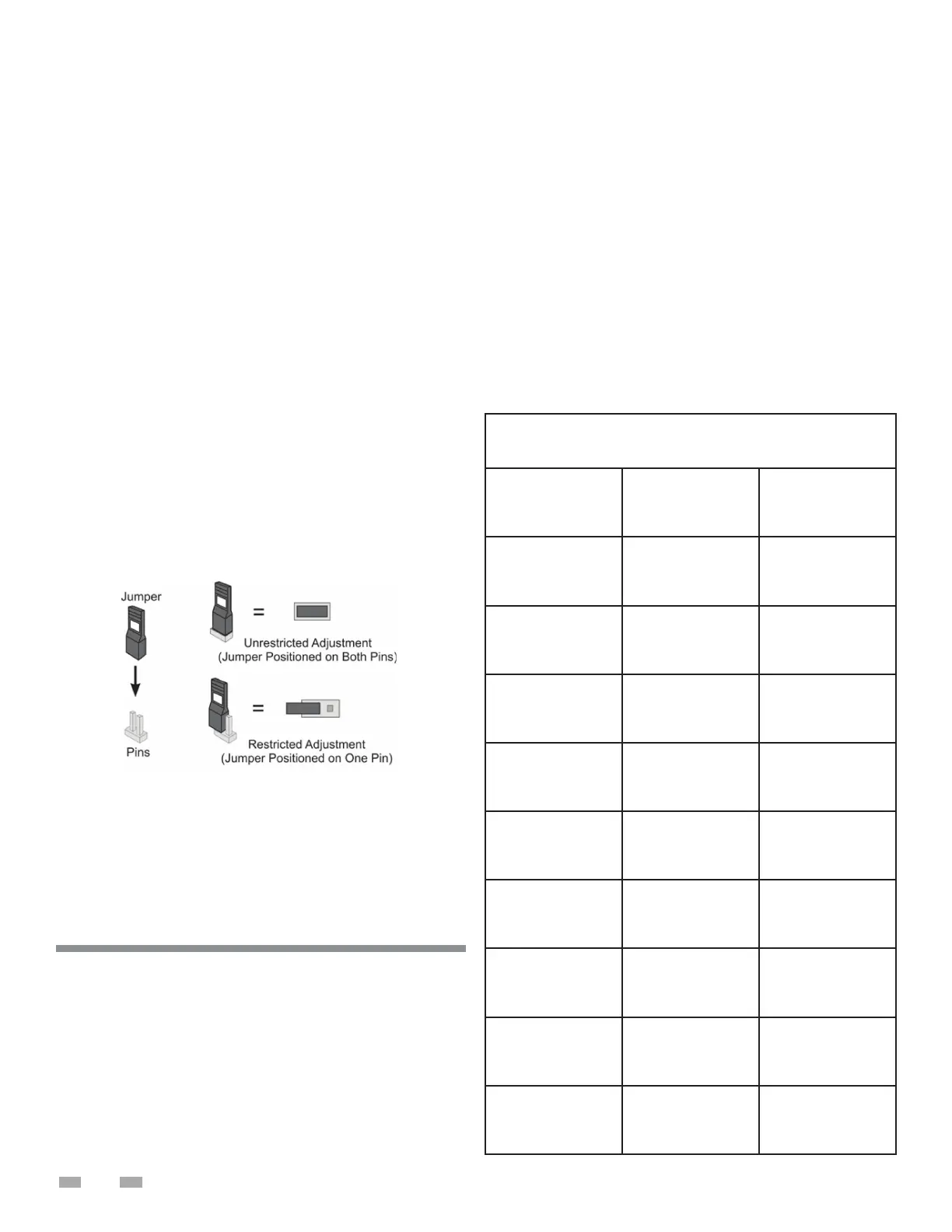

Setpoint Ranges & Safeties

Safety

Factory

Setting

Action

Low Flow

(heating /cooling

side)

< 4.4 Gal/Min Shuto

Evaporator

Temperature

Defrost Cut-In

34° F Shuto

Evaporator

Temperature

Defrost Cut-Out

38° F Alarm

Temperature

Setpoint Range

100° F - 160° F-

High Refrigerant

Pressure

Cut-Out

410 PSI Shuto / Alarm

High Refrigerant

Pressure Cut-in

300 PSI -

Low Refrigerant

Pressure

Cut-Out

12 PSI Shuto / Alarm

Low Refrigerant

Pressure Cut-In

15 PSI -

Compressor

Anti-Short

Cycle Delay

300 Sec -

So: Sensor O set allows for compensation of any di erence

between the displayed temperature and the temperature being

read by the sensor.

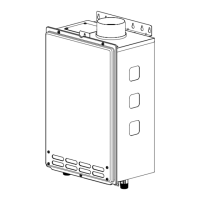

ESTICTED MODE

Switching the Controller to Restricted Mode will prevent users

from adjusting most or all of the parameter settings. The main

screen will function normally.

Note: The OFF parameter is the only parameter that can be

accessed in Restricted Mode. So be sure that your desired

parameter values are set before changing over to restricted

mode.

In addition, the di erential between the OFF/ON parameters

is xed in restricted mode. If the OFF parameter is adjusted

the On parameter will adjust to maintain the di erential.

Setting the controller to restricted mode:

• Turn power o from the controller

• Carefully remove the front panel

• Locate the jumper and carefully position it on one pin as

shown in the diagram below.

The controller is now in restricted mode. Securely replace the

cover before reconnecting power to the controller.

Lock out

You can format your parameters to completely restrict all user

adjustment of the control when in restricted mode. To do this

set the HtS value equal to the OFF value and the LtS equal to

the On value. This makes the OFF/On range equal to the HtS/

LtS range and thereby unadjustable in restricted mode.

PLC CONTOLLE

Your units may be equipped with a Programmable Logic Controller

(PLC) and Human-Machine Interface (HMI) for controlling the

water heating process. Sensors within the system provide

operating information to the PLC which uses this information

to safely control the heating process. The control comes with

a pre-set water high temperature setpoint of 120°F. The control is

limited to a maximum water high temperature setpoint of 160°F.

Operating at higher temperatures could void the warranty.

TEMPEATUE & SETPOINTS

To view and adjust the temperature setpoint, follow these

steps.

• View the HMI mounted on the electrical panel door.

Locate the “High Temp” value on the setup screen.

• Touch the box representing the current value. A keypad

and cursor will appear.

• Enter the desired temperature setpoint (maximum 160°F)

• Touch the return, or enter key on the keypad. The

display will return to the info screen, and your entered

value should be displayed in the “high Temp” value box.

The unit is now set to heat up to the new setpoint

temperature.

Note: Until the Return key is pressed, the unit will run

based upon the previous setpoint temperature.

PROGRAMMABLE LOGIC CONTROLS

Loading...

Loading...