24

CONFIGURATION SCREEN

“Comp HRS” – Compressor Hours: indicates the compressor

run time hours of each unit

“Pump %” - Percentage of envelope sent to pump via

communication connection.

“Pump Staging” - Percentage of pump envelope called

depending on how many heat pumps are running.

“Pump Testing” - Used to hold system at a specific % for

setting Pump Staging values.

“Tank Di Set” – Tank Di erential Setpoint: sets the minimum

tank temperature rise required to avoid calling another unit

“System Timer” – System Timer: sets the maximum time that

the tank has to achieve the Tank Di Set value to avoid calling

another unit

“TempDiff” – Temperature Difference: sets the difference

below the setpoint where the master will give a call for members

to run

“SAVE”button – Saves the“Tank Di Set”and“System Timer”

parameters

“Master IP Address” – IP Address used to connect panel to

BMS system

“Master IP Subnet” – subnet mask for address range IP is

con gured in

“Master IP Gateway” – IP Address for internet router on site

used to connect to unit via VPN

MASTE CONTOL PANEL SETUP TO

MEMBE UNITS

1. Hardwire all member units to individual power sources

rated for the equipment with disconnects

2. Hardwire the “Master Control Panel” to a 120V power supply

through the junction box

3. Hardwire each temperature probe into the junction box

for the Master Control Panel and then permanently attach

them to their respective tanks

4. Connect all of the member units to the router in the

junction box

5. Under the con guration screen press the “SEARCH FOR

UNITS” button to nd all of the connected members (give

the master controls 2 minutes to nd all of the member

units)

MASTE CONTOL UNIT CALL SEQUENCE

OF OPEATIONS

1. Set the “Tank Diff Set” value to 1°F and the “System

Timer” value to 300s (5min), then press save to update

the program

2. Once the master panel determines that there needs to be

a heat call it will determine the unit call order based on;

compressor run hours, alarm status, and unit number. Then

the master will call the unit in the rst unit in the run order

to turn on

3. If the tank temperature does not increase 1°F in 300

seconds than the second unit in the run order will be

called to run

4. The master controls will keep reevaluating these

conditions and calling units as necessary to achieve

the desired rise in the desired amount of time

5. If you nd that the units are not turning on fast enough

to meet building demand change the “System Timer” to a

smaller value in order to have units turn on quicker

6. If you nd that too many units are turning on and meeting

the building demand very quickly (almost in a manner of

short cycling) you should try increasing the “Tank Di Set”

value so that additional units will only turn on as needed

MEMBE SCEENS

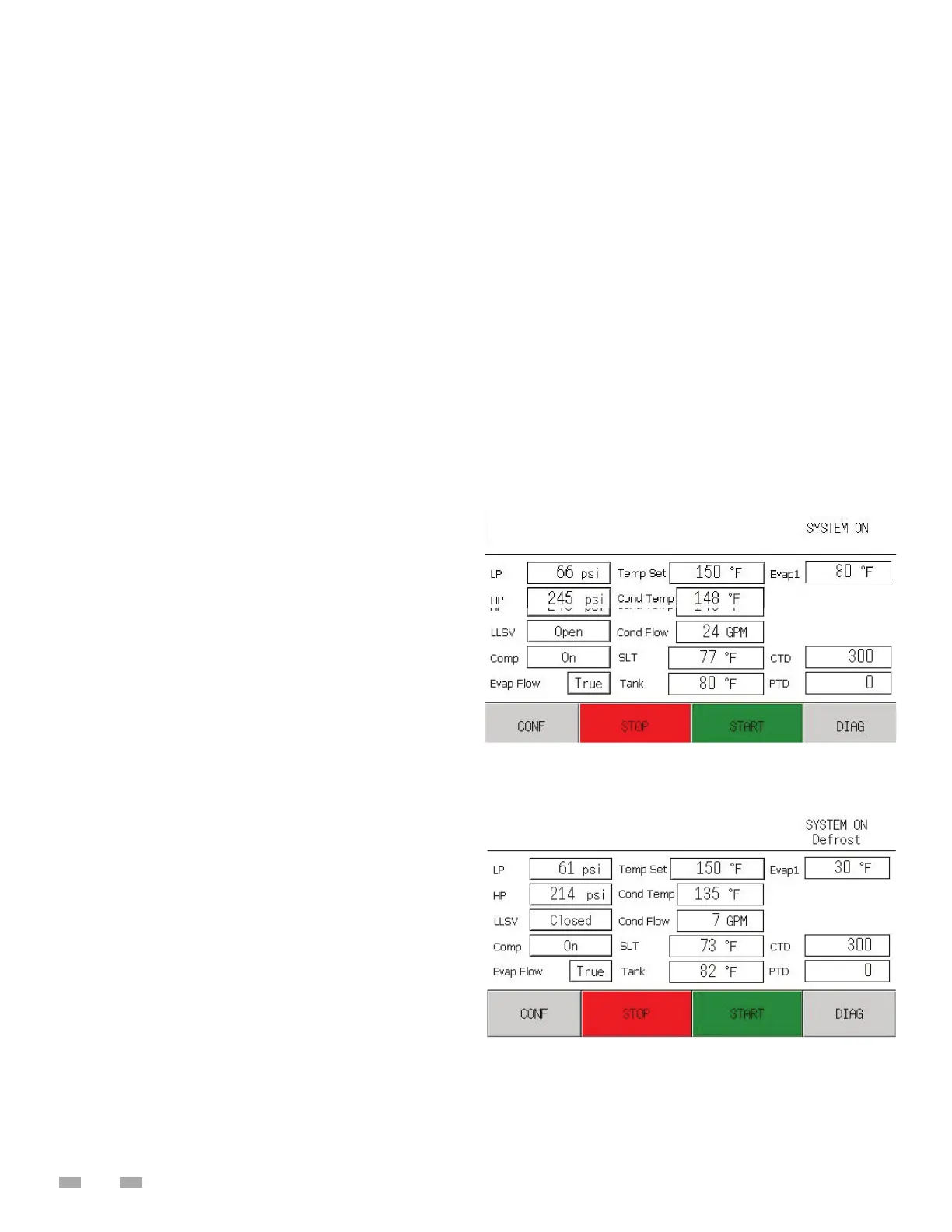

SINGLE UNIT HOME SCREEN OPERATING WITH

MASTER CONTROLS

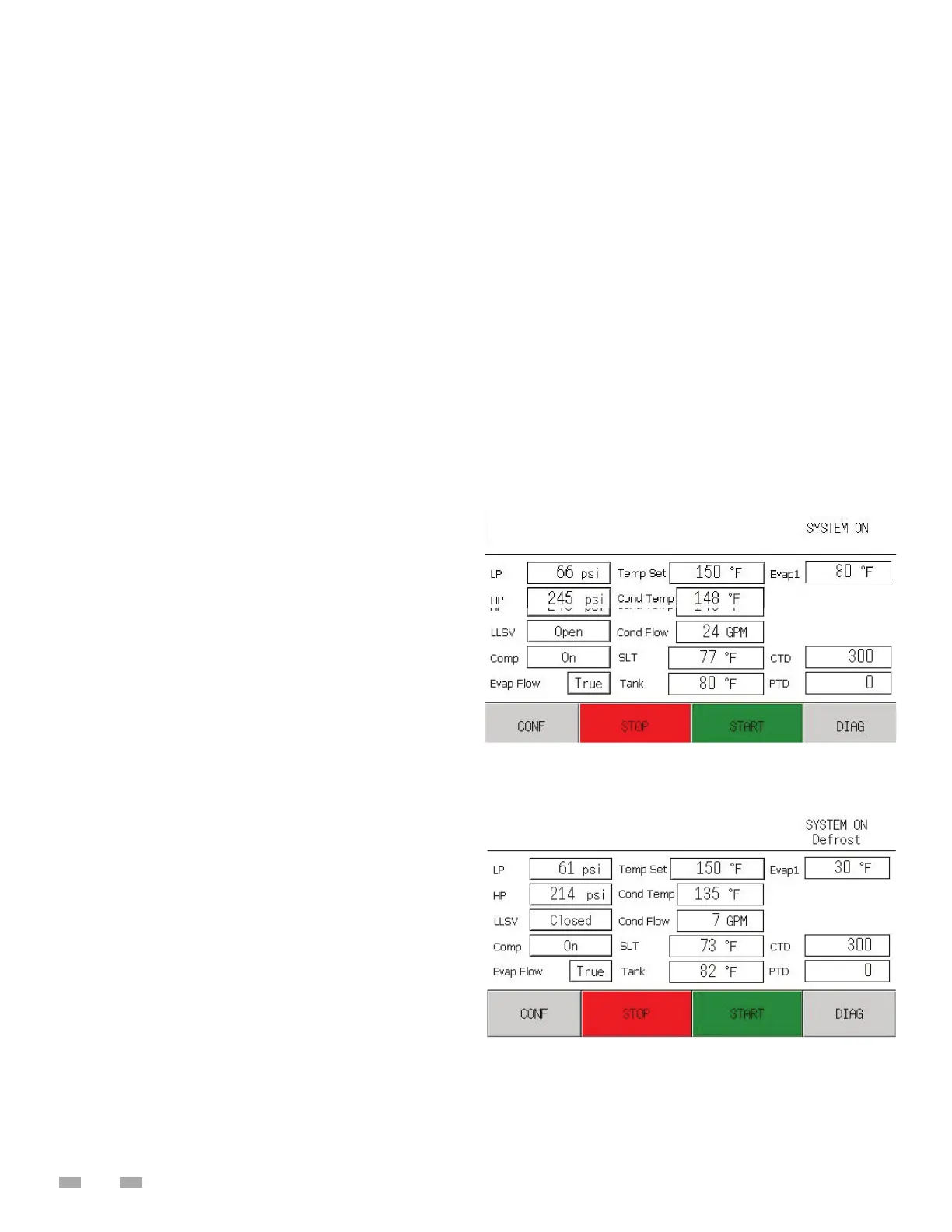

SINGLE UNIT HOME SCREEN OPERATING AS A

SINGLE UNIT (IN DEFROST)

Loading...

Loading...