42

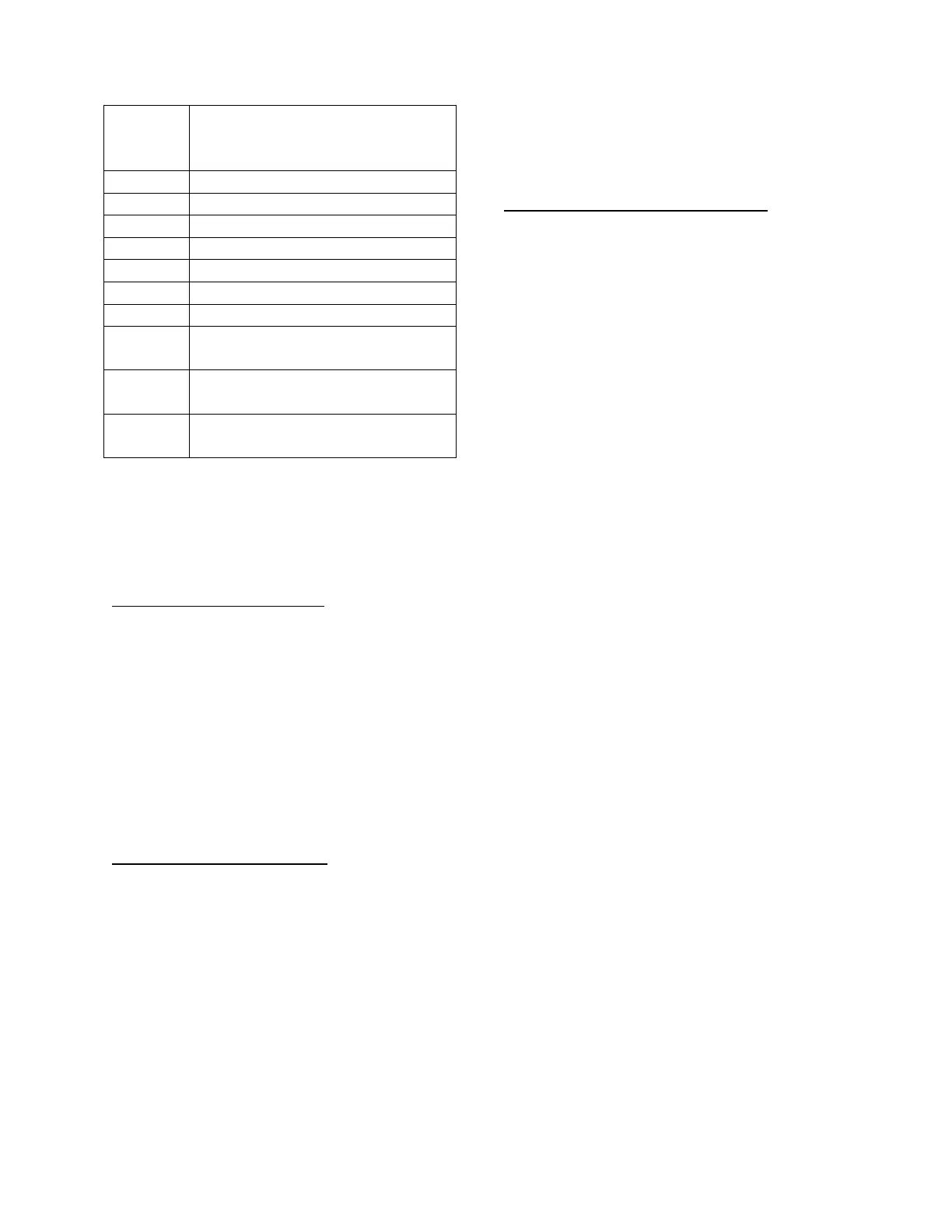

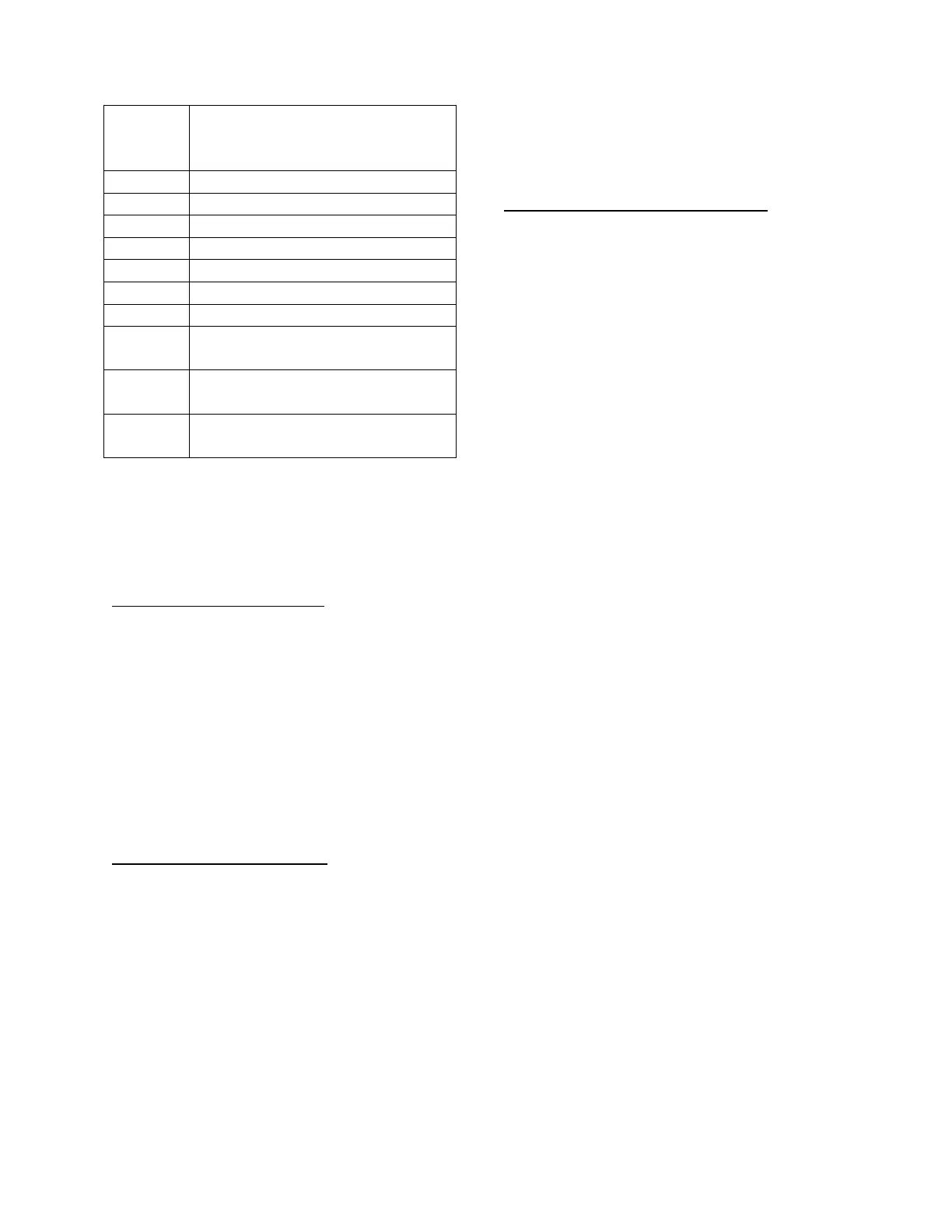

Table 8 - LED Diagnostic Codes

High Condensate Level Alarm

Low Control Voltage Alarm

High Control Voltage Alarm

Leaving Water Temperature

Alarm

Air Coil Low Temperature

Alarm

Entering Water Temperature

Alarm

Automatic Reset Alarms

The following alarms will automatically

reset themselves once the fault condition

clears.

Low Control Voltage Alarm

The low voltage alarm will activate when

the 24VAC control voltage drops to 20VAC

+/-5%. Below this voltage the onboard

normally open relays are not guaranteed to

close. The low voltage alarm will release

when the voltage rises above 22VAC +/-5%.

Once the fault is cleared the controller will

activate a random start delay. This alarm

will disable the compressor, the supply fan,

and the reversing valve.

High Control Voltage Alarm

The high voltage alarm will activate when

the 24VAC control voltage increases to

32VAC +/-5%. Any voltage higher than

this risks damaging components on the

control board. The alarm will release when

the control voltage decreases to 30VAC +/-

5%. Once the fault is cleared the controller

will activate a random start delay. This

alarm will disable the compressor, the

supply fan, and the reversing valve.

Leaving Water Temperature Alarm

To prevent freezing of the liquid heat

exchanger, the leaving water temperature

alarm will activate and turn the compressor

off if the refrigerant saturated suction

temperature during heating drops below the

freeze protection temperature setpoints in

Table 9 - Glycol Percentage Setpoints, based

on the glycol percentage that is input into

the controller. The alarm will deactivate

(allowing the compressor to run again) after

ten minutes have expired and the refrigerant

saturated suction temperature rises 5°F

above the freeze protection temperature. If

the alarm is activated again within two

hours, the refrigerant saturated suction

temperature must rise 5°F above the freeze

protection temperature and the unit power

must be cycled off and on or the compressor

activation call from the thermostat must be

removed and then restarted.

The glycol percentage DIP switch “SW1” is

used to set the glycol percentage that is used

in the system for freeze protection. This

switch is located in the center of the control

board. The freeze protection setpoints

change based on the glycol percentage that

is input to the controller. It is critical that

this setting matches the actual glycol

percentage used in the system to prevent

damage caused from freezing. Inputting a

glycol percentage that is higher than actually

used in the system can cause extensive

damage from freezing.

Loading...

Loading...