14

During the cooling season, if the airflow is

reduced due to dirty air filters or any other

reason, the cooling coils can get too cold

which can cause excessive liquid to return to

the compressor. As the liquid concentration

builds up, oil is washed out of the

compressor, leaving it starved for

lubrication.

The compressor life will be seriously

shortened by reduced lubrication and the

pumping of excessive amounts of liquid oil

and refrigerant.

Wiring Diagrams

Unit specific wiring diagrams are affixed

inside the control compartment panel.

Installation

AAON equipment has been designed for

quick and easy installation.

Before startup of the unit, check the supply

blower and remove the foam shipping block

that may be included to support the blower

assembly before installation, or damage may

occur.

Figure 2 - Foam Shipping Block

Locating the Unit

Placement of the unit relative to ductwork,

electrical and plumbing must be carefully

considered. Supply and return air plenum or

duct can be mounted directly to the duct

connection flanges. Use a properly sized

duct transition to connect supply duct to unit

supply air opening. Return duct flanges are

only included on units with the optional 4-

sided filter rack. Use flexible gasket material

to seal the duct to the unit.

Verify ceiling, floor, or foundation can

support the total unit weight, including

accessory weights.

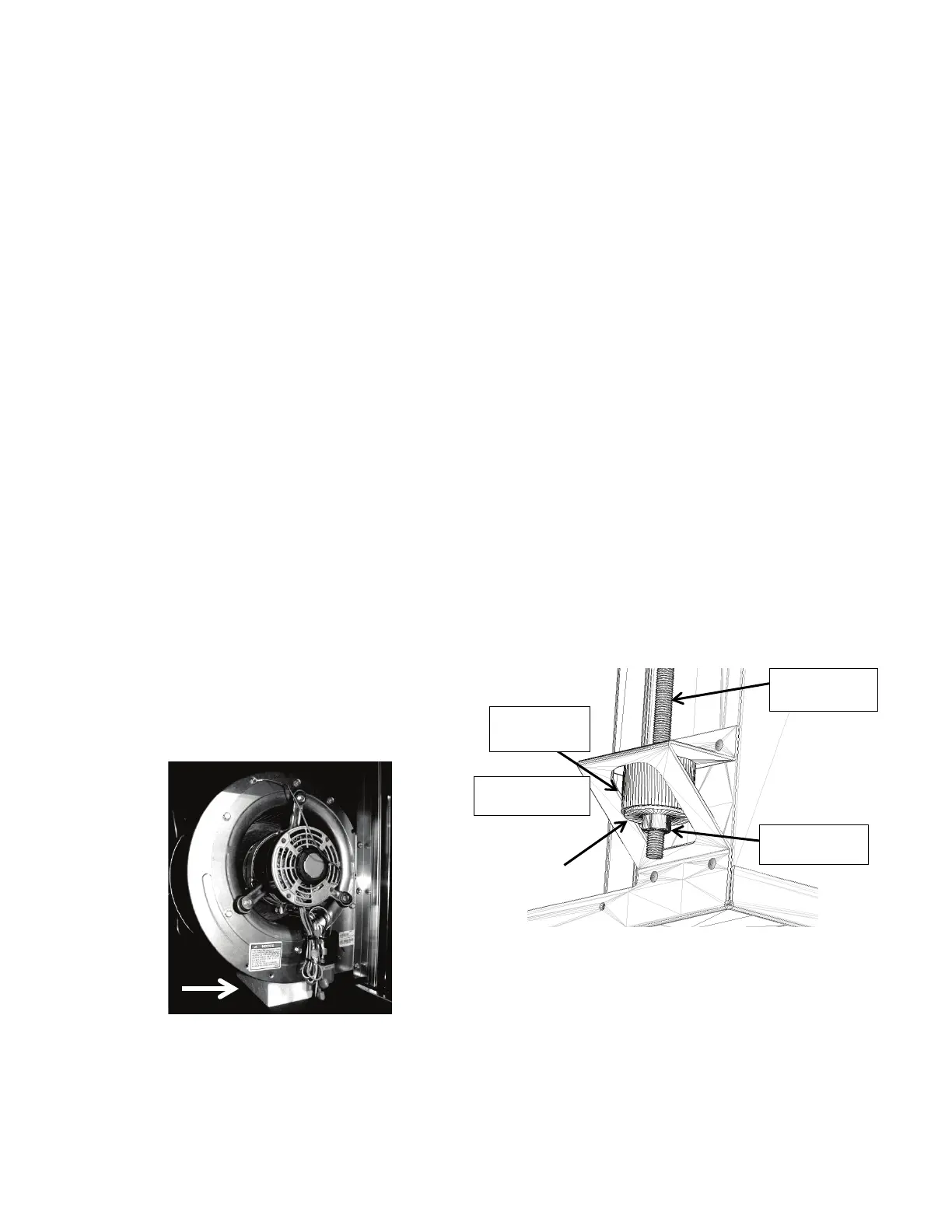

To properly support the horizontal WSHP

unit and reduce sound and vibration, it must

be mounted level in both horizontal

directions. These units are designed to be

suspended via threaded rod (field provided)

through all four hanger brackets using the

four (4) vibration grommets (factory

provided) and 3/8” washers (field provided)

and as shown in Figure 3.

Figure 3 - Mounting Horizontal Units

Vibration grommets are factory provided

and must be field installed on units 6 tons

and larger.

(Field Provided)

3/8” Washer

(Field Provided)

Grommet

Loading...

Loading...