29

Installing contractor must check for proper

motor rotation and check blower motor

amperage listed on the motor nameplate is

not exceeded.

Wire control signals to the unit’s low

voltage thermostat connections on the

control board, located in the controls

compartment. Consult unit wiring diagram

for more detailed instructions on control

signal wiring connections.

If any factory installed wiring must be

replaced, use a minimum 105°C type AWM

insulated conductors.

How to Connect to WH Series Disconnect

30 Amp Disconnect

1) Remove compressor panel

Electrical knock-outs are available next

to the switch to run the wire through.

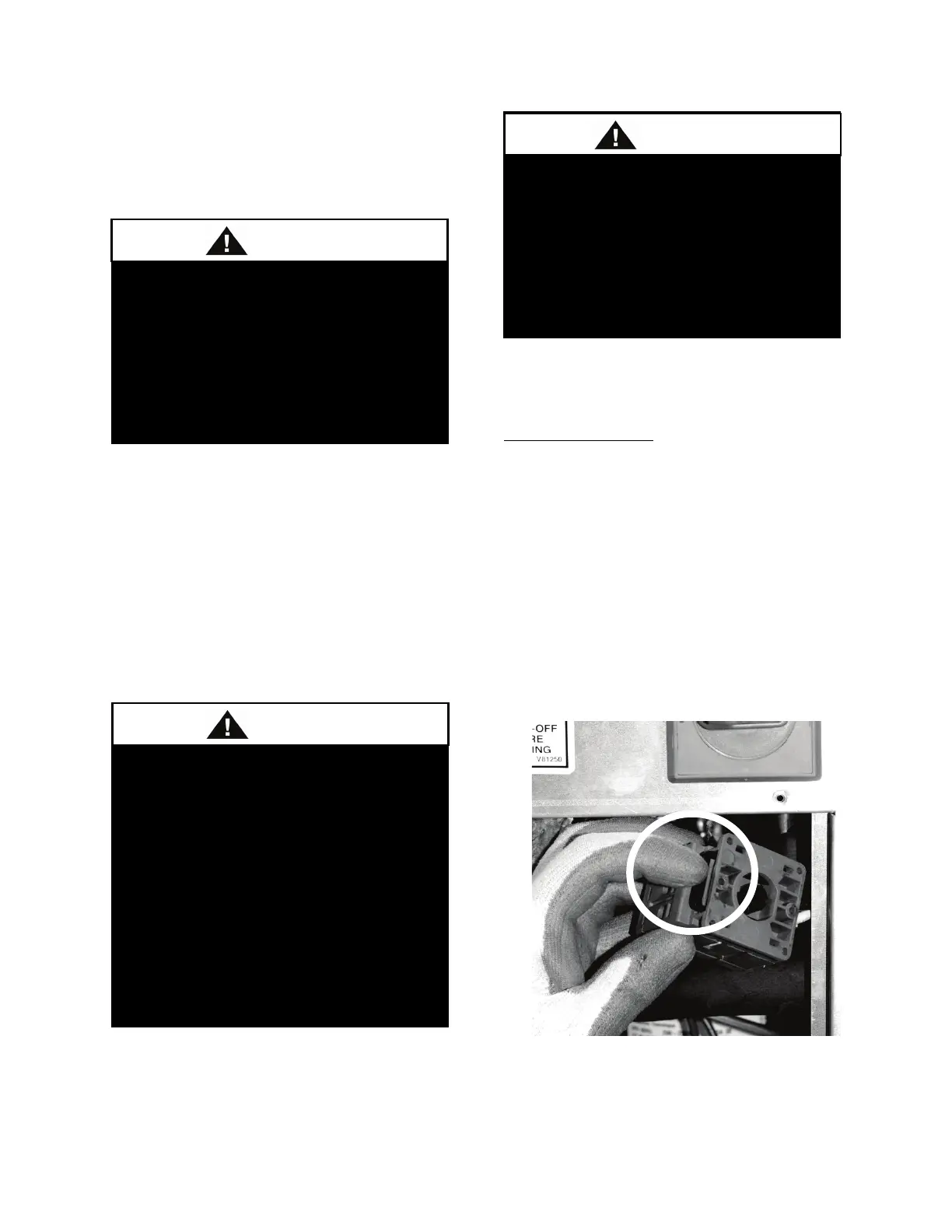

2) Reach behind the Disconnect Switch,

grasp the terminal block and press down

on the button, and pull back to remove

from rotary switch.

The button to release the terminal block:

Figure 14 - Release Button

Rotation must be checked on all

MOTORS AND COMPRESSORS of

three phase units. Supply fan motors

must all be checked by a qualified

service technician at startup and any

wiring alteration must only be made

at the unit power connection.

Scroll compressors are directional

and can be damaged if rotated in the

wrong direction. Compressor rotation

must be checked for proper

operation, without using external

refrigerant pressure gauges. Often, a

compressor running in reverse

rotation will be much louder than a

norm

al compressor, and will not

develop much of a temperature

differential between the suction and

Disconnect all electrical power

sources before servicing the unit.

More than one power source may be

provided. Failure to do so may result

in injury or death from electrical

shock or entanglement in moving

parts/

Loading...

Loading...