Manual for High Voltage Process Performance Motors

50 - Maintenance

3BFP 000 063 R0101 REV D

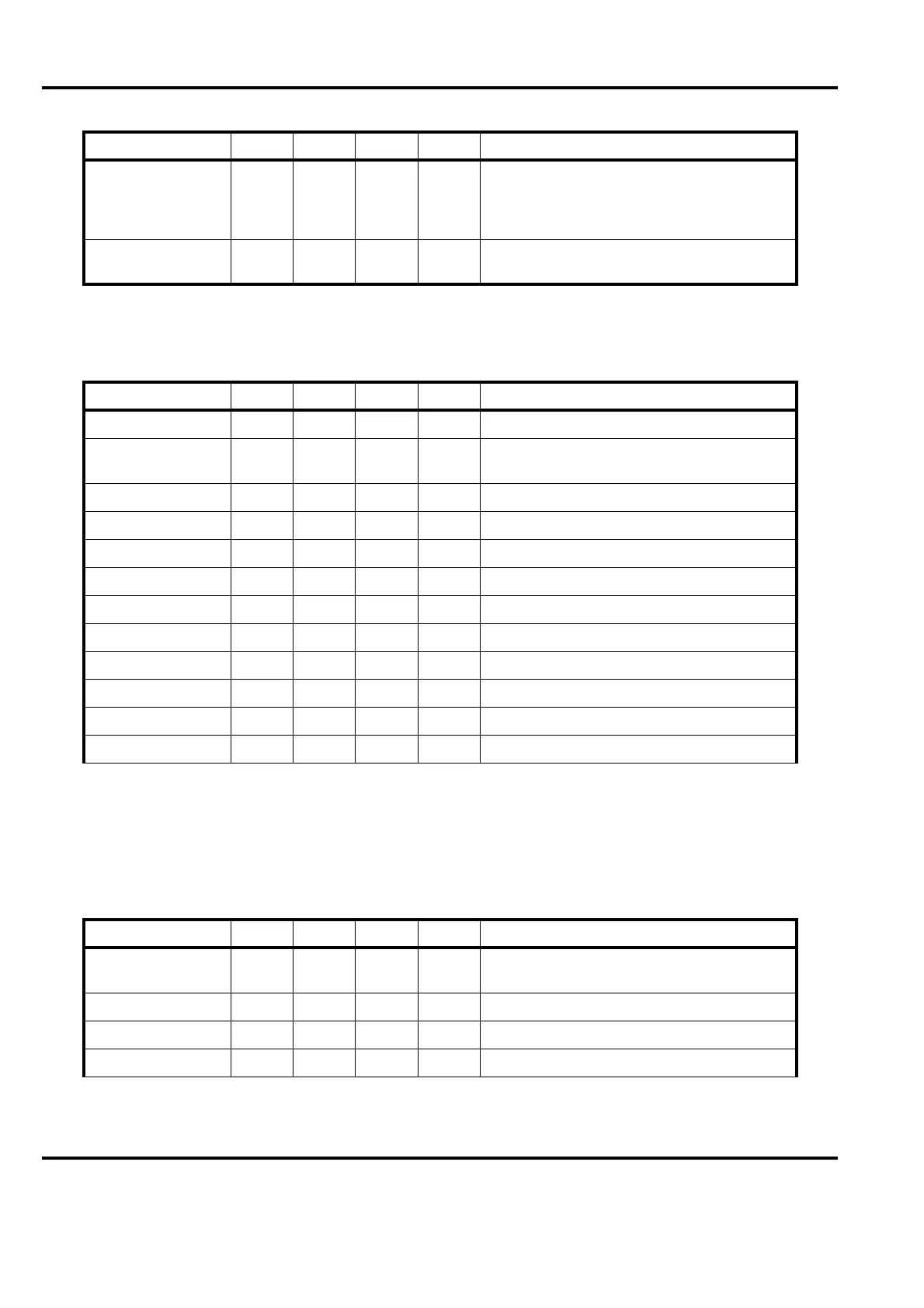

7.3.1.2 Stator and rotor

NOTE: It is not recommended that totally enclosed machines are dismantled and inspected

internally more often than every 3-5 years (L3).

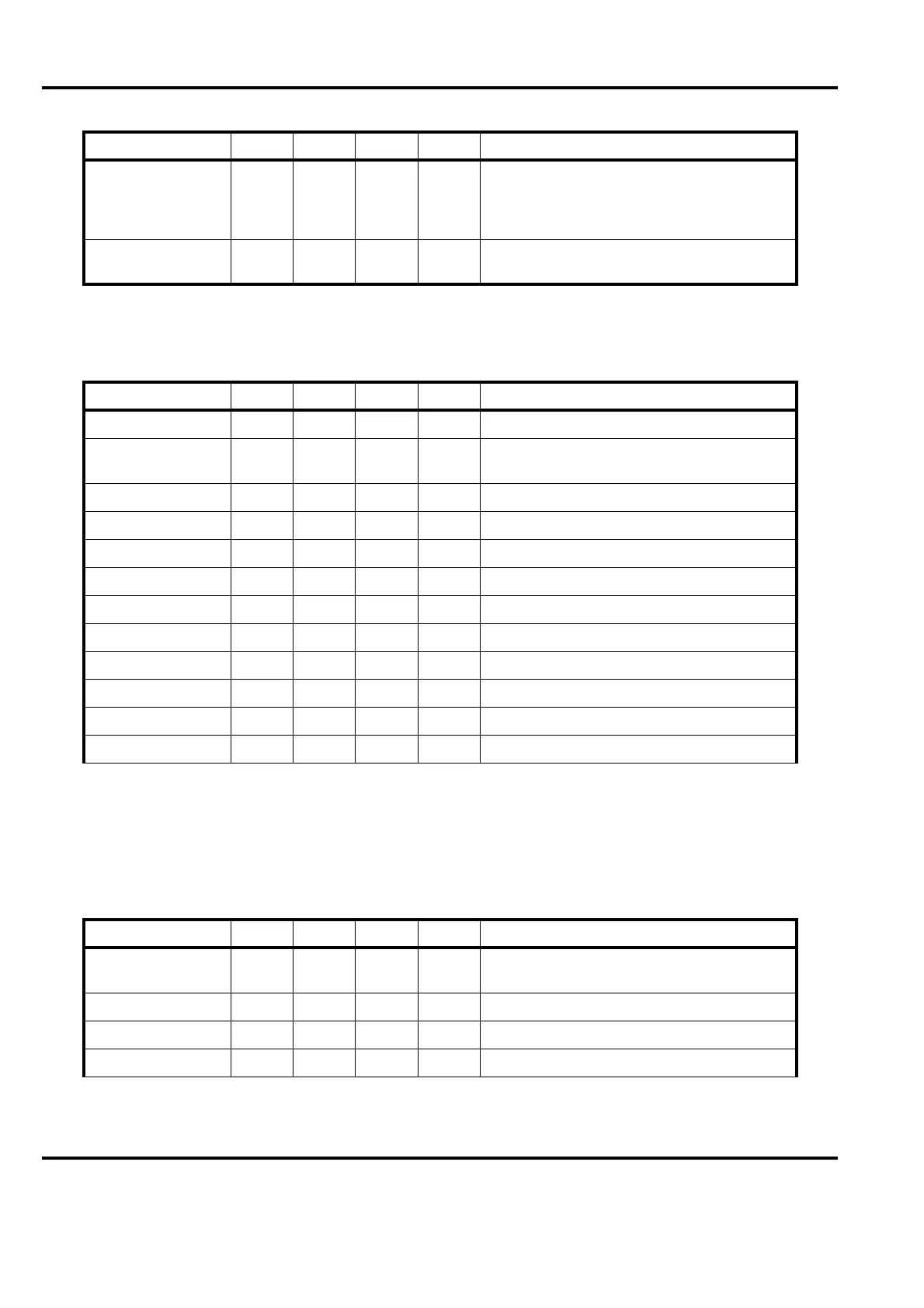

7.3.1.3 Auxiliaries

Terminal box accessories,

i.e. surge capacitors,

arrestors and current

transformers

V V V V General condition

Cable transits V V V V Condition of cables entering the machine and inside the

machine

Maintenance object L1 L2 L3 L4 Check / Test

Stator core V V V V / C Fixing, cracks, welds

Stator winding insulation V V / T V / T / C V / T / C Wear, cleanliness, insulation resistance, turn insulation test,

(high voltage test)

Stator coil over hangs V V V V Insulation damages

Stator coil supports V V V V Insulation damages

Stator slot wedges V V V V Movement, tightness

Stator terminal bars V V V V Fixing, insulation

Instrumentation V V V V Condition of cables and cable ties

Rotor winding insulation V V / T V / T / C V / T / C Wear, cleanliness, insulation resistance

Rotor balancing weights V V V V Movement

Shaft V V V V Crack, corrosion

Connections in rotor V V V / T V / T Fixing, general condition

Earthing brushes V V V V Operation and general condition

Maintenance object L1 L2 L3 L4 Check / Test

Pt-100 elements (stator,

cooling air, bearing)

V V / T V / T V / T Resistance

Anticondensation heaters V V / T V / T V / T Operation, insulation resistance

Encoders V V V / T V / T Operation, general condition, alignment

Auxiliary terminal boxes V V / T V / T V / T General condition, terminals, wiring condition

Maintenance object L1 L2 L3 L4 Check / Test

Loading...

Loading...