AO2000-LS25 LASER ANALYZERS | OI/AO2000-LS25-EN REV. D 11

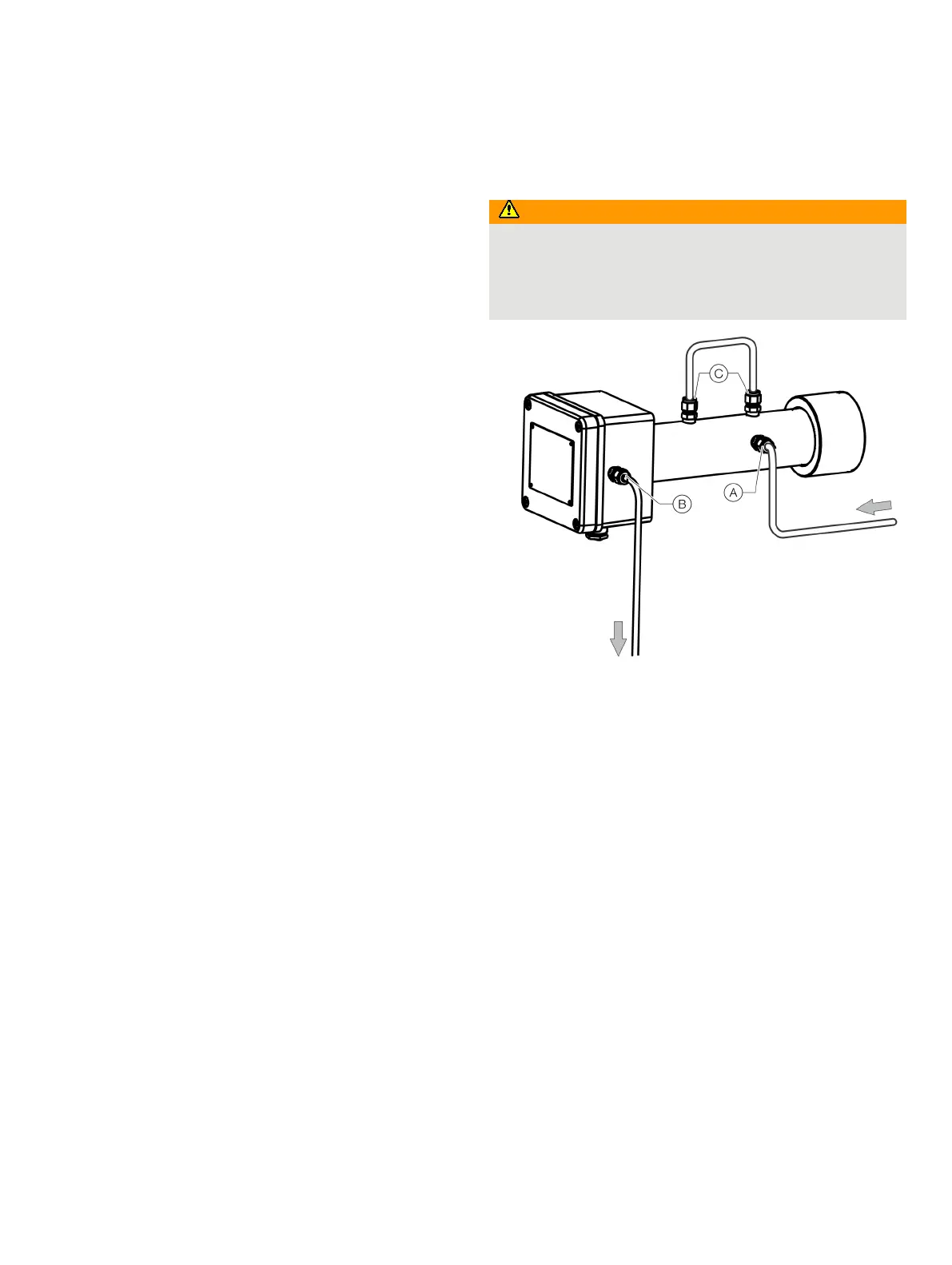

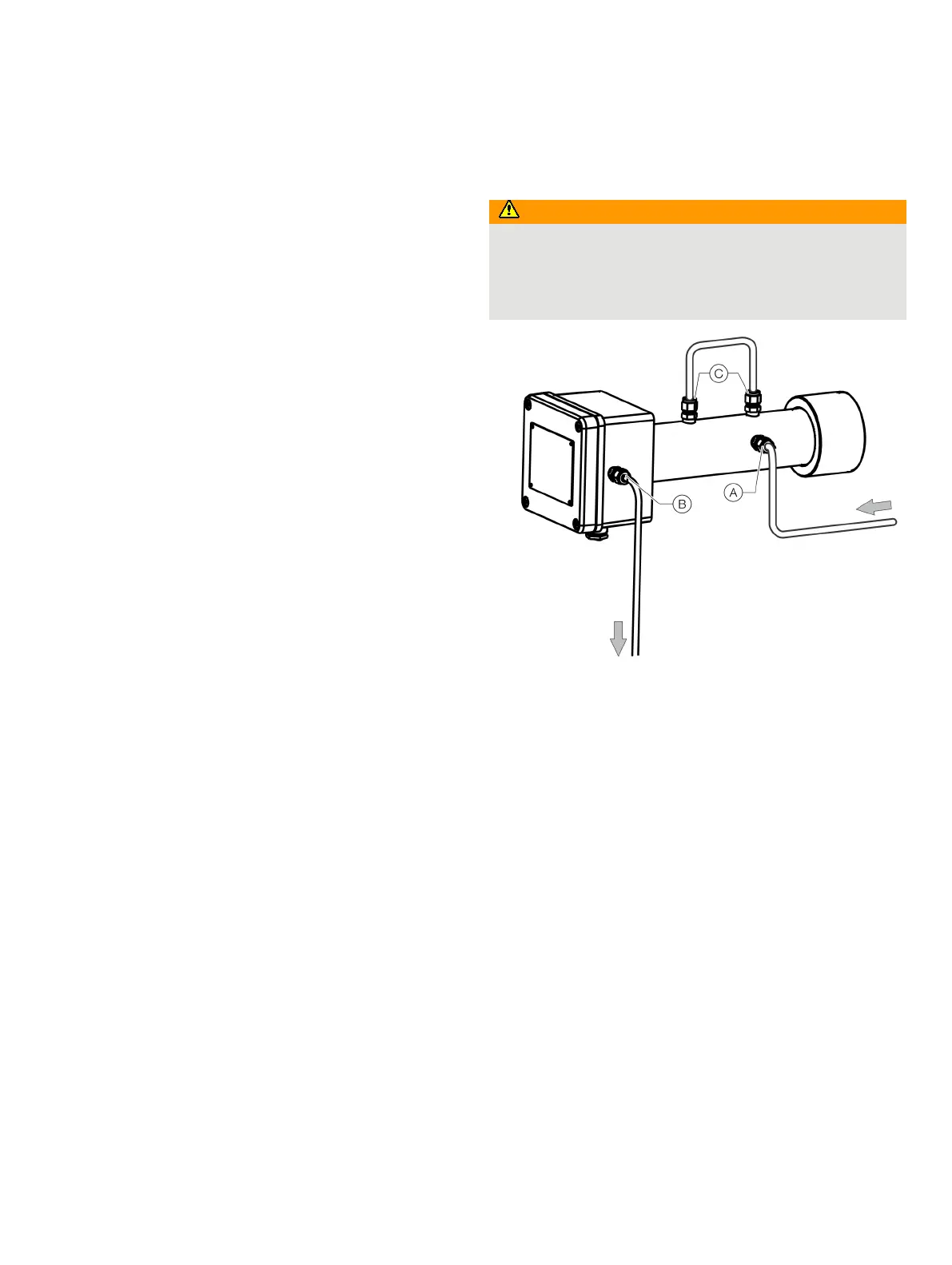

• The purge gas inlet must be connected to the Swagelok®

fitting

A on the receiver unit. Keep gland C closest to the

connection flange free.

• The flow direction of the purge gas must be designed

according to Figure 1 on page 7.

• The electrical inputs/outputs of the device must be routed

via a suitable interface relay. The interface relay is controlled

by the purging and monitoring unit and disconnects the

inputs / outputs on all poles in the event of a fault.

• The operating instructions of the purging and monitoring

unit as well as other components of the pressurized

enclosure must be observed during installation.

• The customer must check and, if necessary, set the process-

specific purge parameters (see Purge parameters for

pressurized enclosure on page 10) in the purging and

monitoring unit during commissioning.

Pressurized enclosure with nitrogen N

2

Risk of suffocation

Risk of suffocation in the event of uncontrolled escaping

nitrogen.

• Ensure that all purge gas lines are tight and that the purge

gas emerges into the outside air in a controlled fashion.

Purge gas entry from the transmitter unit

Purge gas entry to the purging and monitoring unit

Jumper connections

Figure 3: Purge gas connection to the receiver unit (N

2

as purge gas)

If nitrogen purging is required for the measurement (e.g. in high-

temperature applications or small O

2

/ H

2

O measuring ranges),

the purge gas connection must be as shown in Figure 3. The

connection of the transmitter unit is unchanged.

Loading...

Loading...