8 EasyLine EL3000 Series Data Sheet 10/24-4.10 EN Rev. 9

Oxygen analyzer Magnos206

Measurement principle

Paramagnetic behavior of oxygen

Magnetomechanical oxygen analyzer; short 90% response time

Sample component and measurement ranges

Sample component

Oxygen (O

2

)

Smallest measurement range

0–2 vol.-% O

2

Measurement range quantity and limits

2 measurement ranges

Measurement ranges are freely adjustable; they are factory-

set per order to 0–5 or 0–100 or 98–100 vol.-% O

2

.

Largest measurement range

0–100 vol.-% O

2

Measurement ranges should not be set within ignition limits.

Measurement ranges with suppressed zero-point

Suppressed measurement ranges are freely adjustable in the

range 0–100 vol.-% O

2

. Smallest span 2 vol.-% O

2

. The

combination of a suppressed and an initial measurement

range is not possible.

Pressure correction with a pressure sensor is required.

A pressure sensor is installed when the analyzer has been

ordered with suppressed measurement range.

Stability

The following data apply only if all influence factors (e.g. flow

rate, temperature, atmospheric pressure) are constant. They are

based on a span of 2 vol.-% O

2

.

Linearity deviation

≤ 0.5 % of span

Repeatability

≤ 50 ppm O

2

(time base for gas exchange ≥ 5 minutes)

Zero drift

≤ 3 % of span of the smallest measurement range (per order)

per week, minimum 300 ppm O

2

per week; following pro-

longed transport and storage time the drift can be higher

during the first weeks of operation.

Sensitivity drift

≤ 0.1 vol.-% O

2

per week or ≤ 1 % of measured value per week

(not cumulative), whichever is smaller.

≤ 0.25 % of measured value per year, minimum 0.05 vol.-% O

2

per year

Output fluctuation (2 σ)

≤ 25 ppm O

2

at electronic T90 time (static / dynamic) = 3 /0 sec

Detection limit (4 σ)

≤ 50 ppm O

2

at electronic T90 time (static / dynamic) = 3 /0 sec

Influence effects

Flow effect

≤ 0.1 vol.-% O

2

in the 30–90 l/h range

Associated gas effect

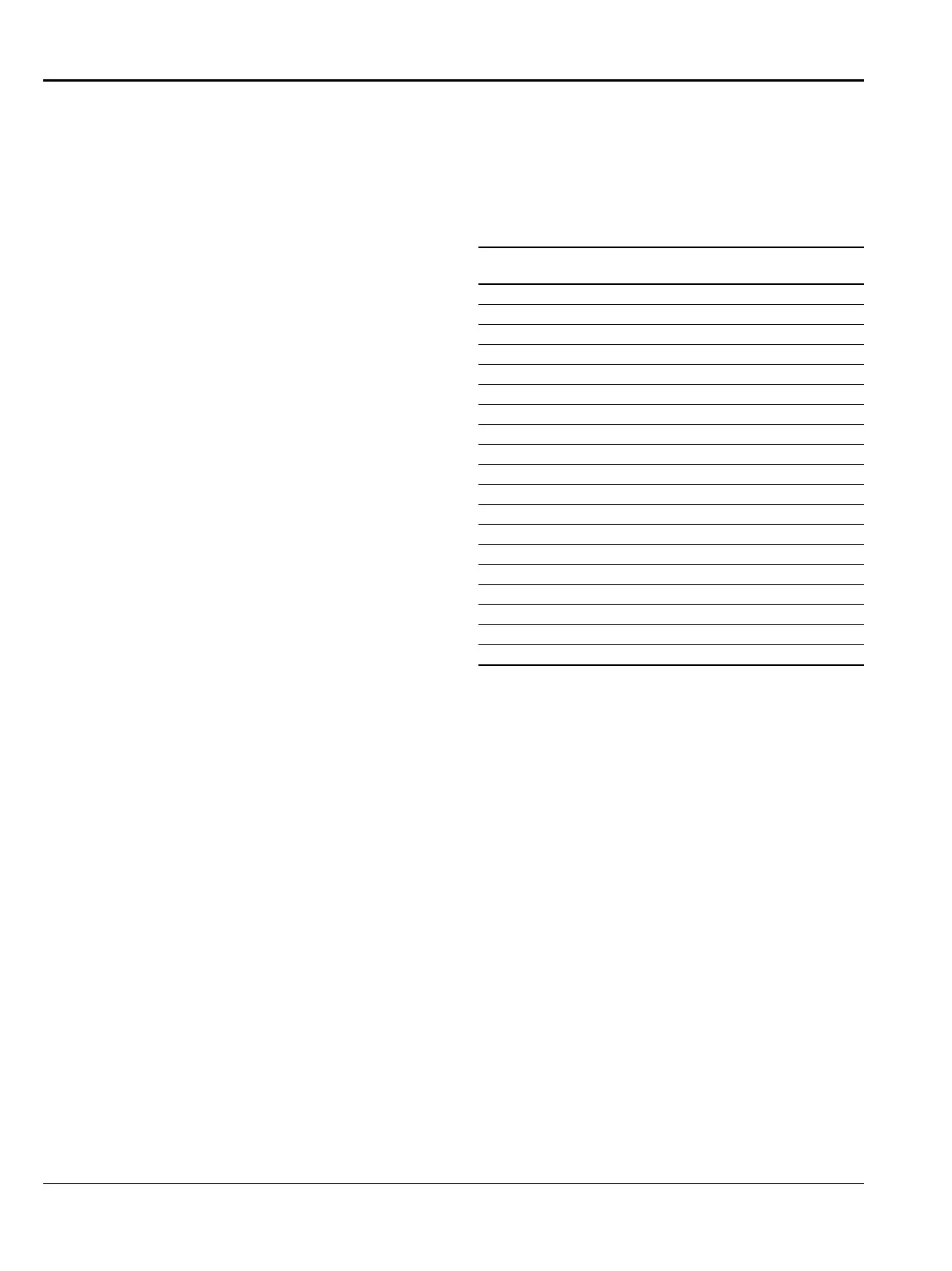

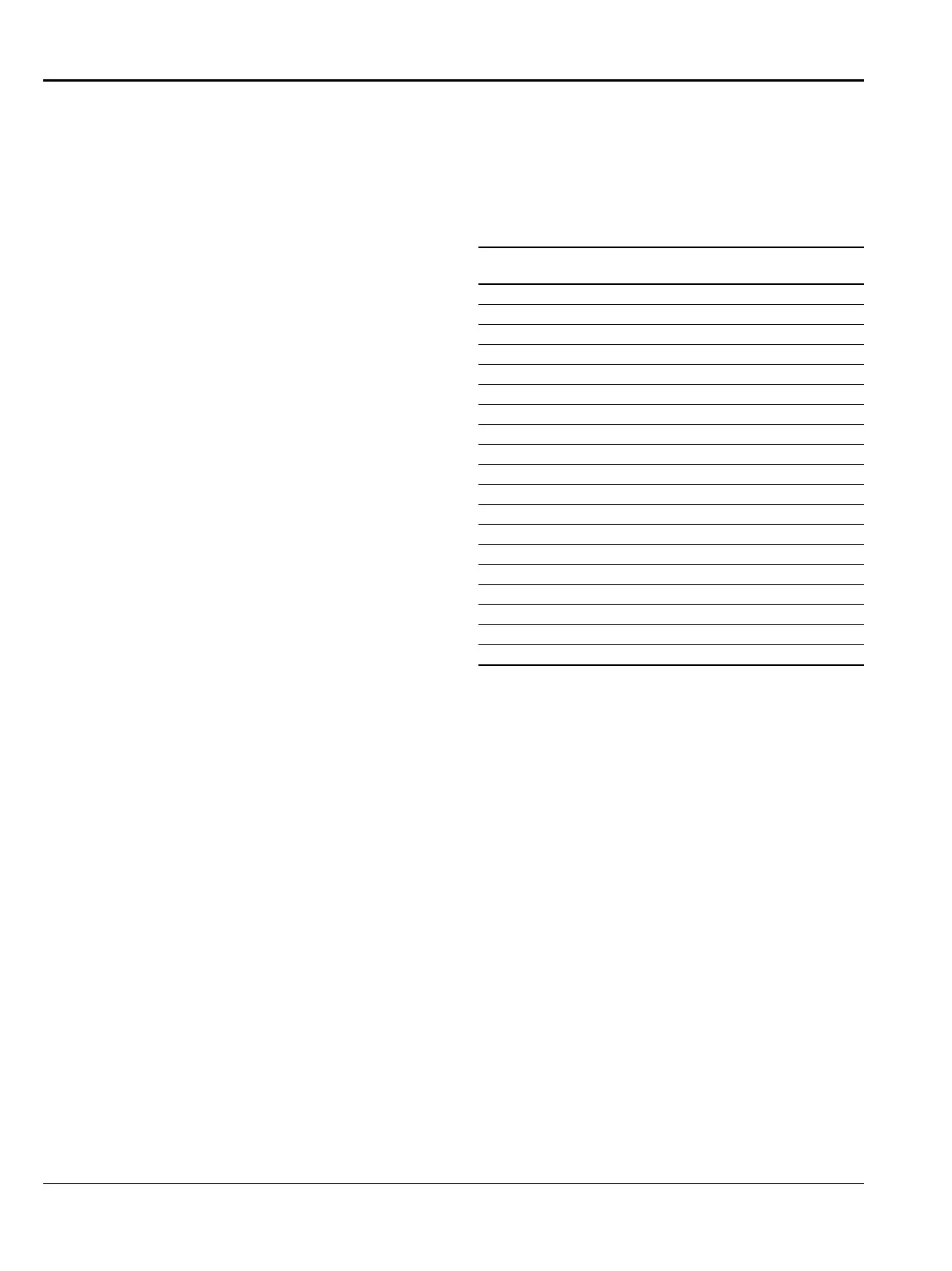

The effect of associated gases as a shift of the zero-point

– expressed in vol.-% O

2

– can be estimated using the

approximate values in the following table:

Associated gas concentration

100 vol.-%

Zero-point shift in

vol.-% O

2

Hydrogen H

2

+0.28

Hydrogen sulfide H

2

S –0.45

Argon Ar –0.26

Helium He +0.30

Neon Ne +0.13

Nitrogen N

2

0.00

Nitrogen oxide NO +43.00

Nitrogen dioxide NO

2

+28.00

Nitrous oxide N

2

O –0.20

Carbon monoxide CO –0.01

Carbon dioxide CO

2

–0.32

Carbon oxysulfide COS –0.90

Ethane C

2

H

6

–0.46

Ethylene C

2

H

4

–0.29

Methane CH

4

–0.24

Propane C

3

H

8

–0.98

Propylene C

3

H

6

–0.55

Trichloroethane C

2

HCl

3

–2.17

Vinyl chloride CH

2

CHCl –0.75

For further associated gases refer to EN 61207-3

Temperature effect

Ambient temperature in the permissible range

– At zero-point: ≤ 1 % of span per 10 °C, ≤ 2 % of span per

10 °C in combination with Uras26

– On sensitivity: ≤ 0.2 % of measured value per 10 °C

Thermostat temperature = 64 °C

Air pressure effect

– At zero-point: No effect

– On sensitivity with no pressure correction:

≤ 1 % of measured value per 1 % air pressure change

– On sensitivity with pressure correction using integrated

pressure sensor (optional):

≤ 0.01 % of measured value per 1 % pressure change or

≤ 0.002 vol.-% O

2

per 1 % pressure change, whichever is

greater

Pressure sensor working range: p

abs

= 600–1250 hPa

Power supply effect

Voltage and frequency in the permissible range: ≤ 0.2 % of

span

Position effect

Zero-point shift ≤ 0.05 vol.-% O

2

per 1° deviation from

horizontal orientation. Position has no effect on the hard-

mounted unit.

Loading...

Loading...