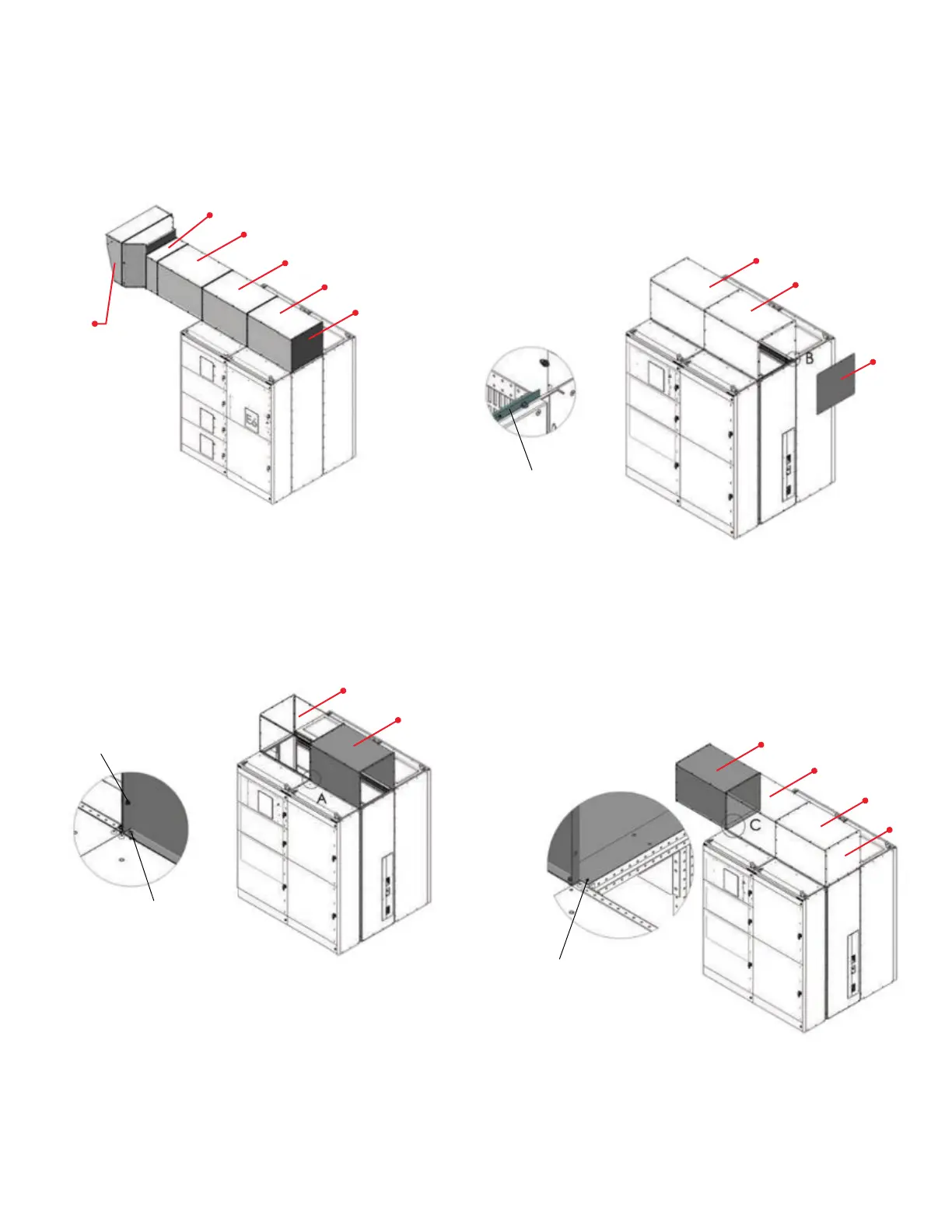

2.1. Install side-exhaust plenum

Extension and end flaps

1. Install the top cover above the busbar compartment,

securing it with the six M6 x 16 screws supplied with

each

section. Torque to 3.5 ft/lbs (4.7 Nm).

2. Connect each top cover to the adjacent cover with 10 M6 x

16 bolts, using the supplied washer and nuts for each bolt.

Torque to 3.5 ft/lbs (4.7 Nm).

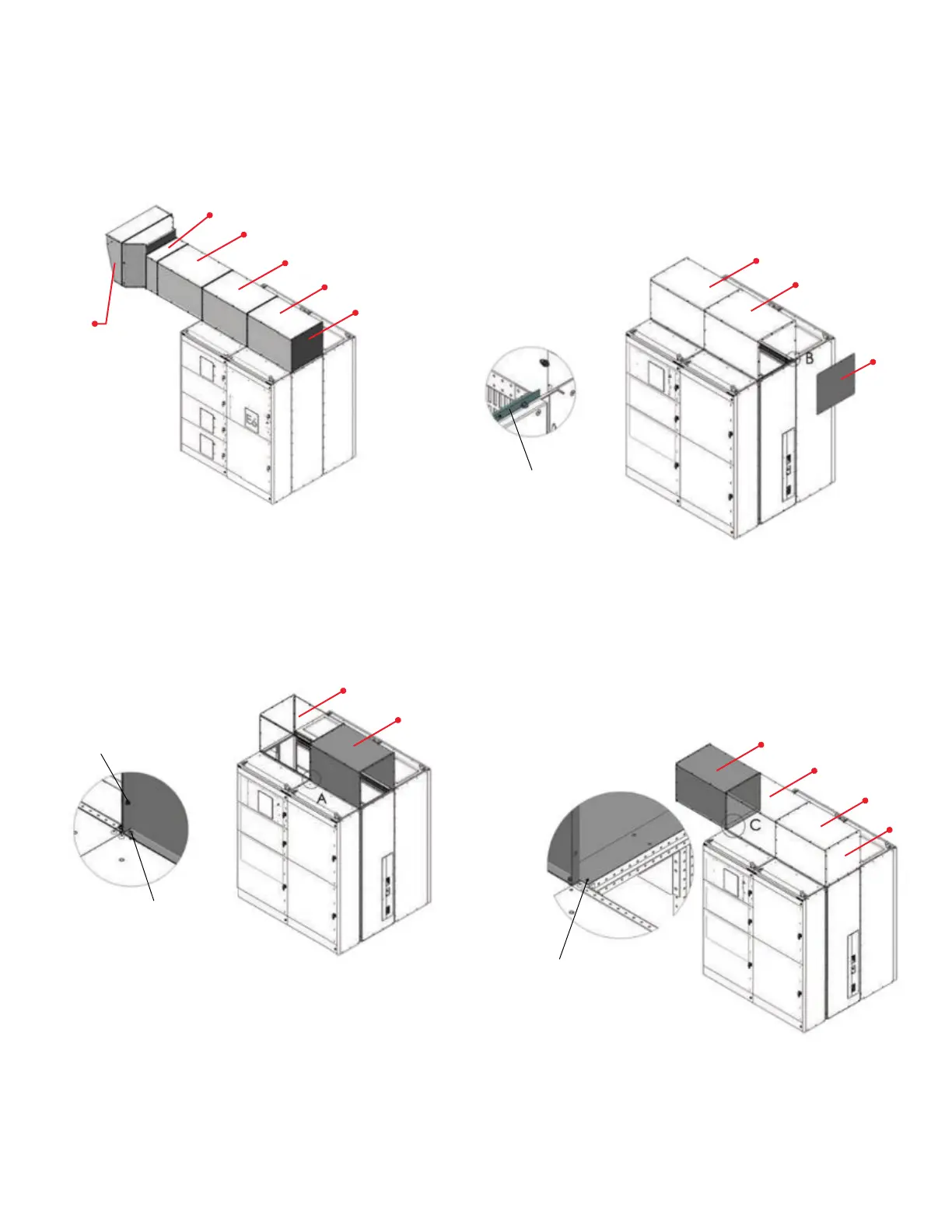

Attach the top covers

3. Place the L-profile rail at the edge of the section

that will

be closed (opposite from the edge on the side of the

section where the plenum will vent).

Attach the L-profile

using four M6 x 16 screws.

Torque to 3.5 ft/lbs (4.7 Nm).

4. Install the end cover by inserting the rivet screws

through the L-profile and into the end cover, then

securing the cover in place with 10 M6-1 x 16 bolts,

using

the supplied washer and nuts for each bolt.

Attach end cover

5. After installing the top and end covers, install the

extension connection on the plenum. Attach the

extension to the switchgear section frame using four

M6

x 16 screws. Torque to 3.5 ft/lbs (4.7 Nm).

6. Attach the extension connection to switchgear frame

with 4 M6 x 16 screws, and to the top cover with 10 M61 x

16 bolts, using the supplied washers and

nuts for each

bolt.

Extension connector

7. Once the extension connection is in place, attach

additional extensions as needed to create the needed

plenum length. Connect each extension using 14 M61 x 16

bolts, washers and nuts. Torque to 3.5 ft/lbs (4.7 Nm).

Loading...

Loading...