-

Supporting brackets, beams, enclosures and foundation

frames should be painted or treated with corrosion-

resistant coating. To facilitate installation and

maintenance, the site should also have:

-

Convenient alignment with other equipment.

-

Accessibility for maintenance.

-

Adequate lighting.

-

Free access to the electrical equipment rooms.

4.2. Installation guidelines

Follow all instructions related to the installation of the

switchgear to avoid potentially hazardous situations that

could result in serious injury or death.

If the installation is being done near operational equipment,

it may be appropriate to erect temporary

barriers between

that equipment and the switchgear.

If you are adding sections to existing switchgear, turn off

all

power supplying this equipment before working on or

inside it.

Always use an appropriate voltage-sensing device to

confirm that the power is off prior to installing or working

with the switchgear.

Follow appropriate lockout/tagout procedures.

4.3. Section installation sequence

Sections can be installed or added in any order, and new

sections may be added between existing sections. If the

sequential order designated during manufacturing is

altered onsite by adding sections to an existing lineup,

the

main bussing must match; and the related drawings

must

be updated.

When adding, removing or rearranging sections, do not

exceed the maximum amperage available on the horizontal

bussing.

4.4. Install and connect shipping splits

NOTE: Diagrams showing the location of fasteners and the

appropriate torque values can be found in the

Torque Table

section of this manual.

4.4.1. Position shipping splits

Remove the shipping splits from their pallets or skids. If

you need to support a multiple- section shipping split at

the base after removing it from the pallet, use

supports at

the corner of each section. Don’t support

the shipping

split only at the four outer corners.

Position the shipping splits in their final arrangement

and

location. Connecting the sections together before

attaching

them to the floor and/or wall will simplify splicing the

horizontal bus.

If doors won’t close easily or panels are twisted or stressed,

this may indicate that the site is not leveled.

You may be able

to shim the sections to level them.

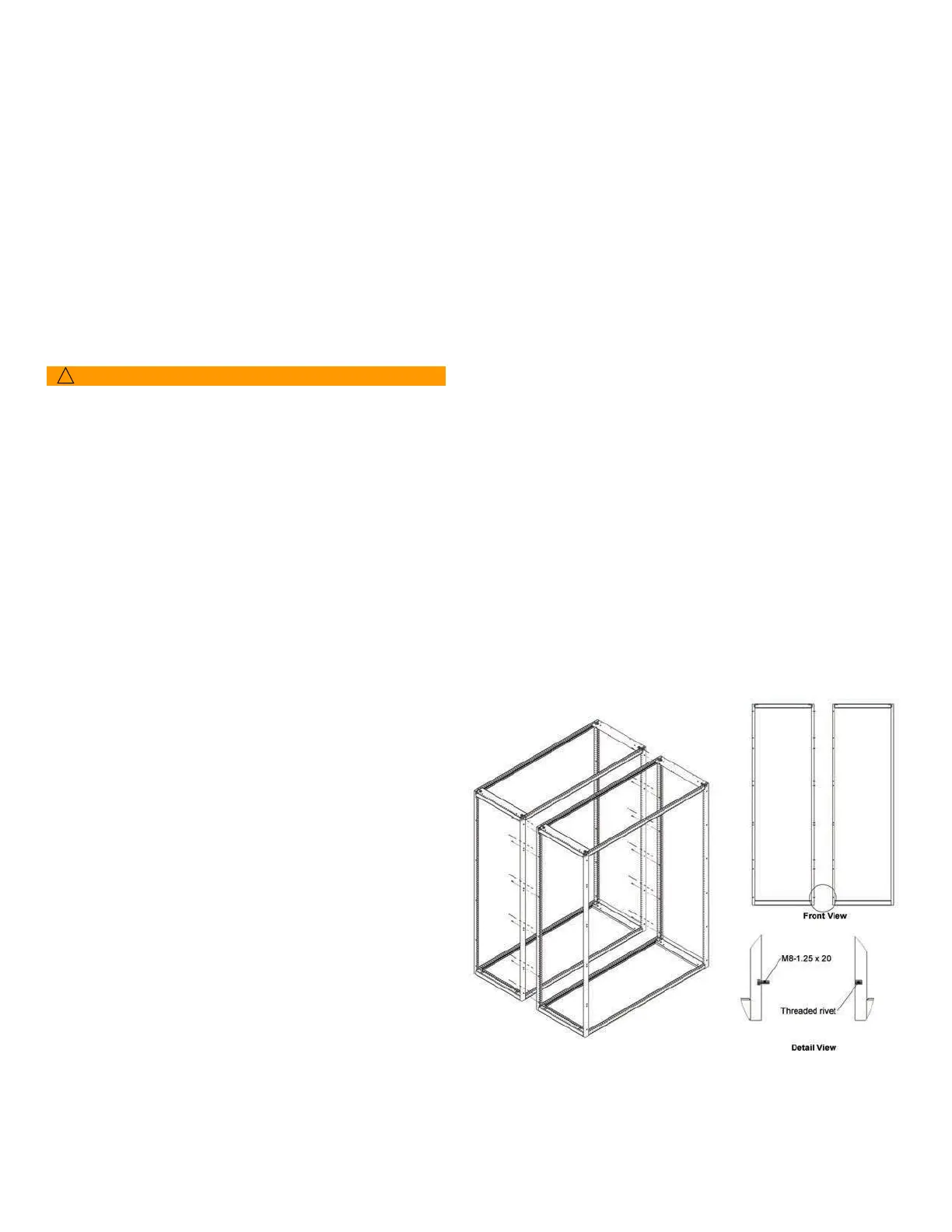

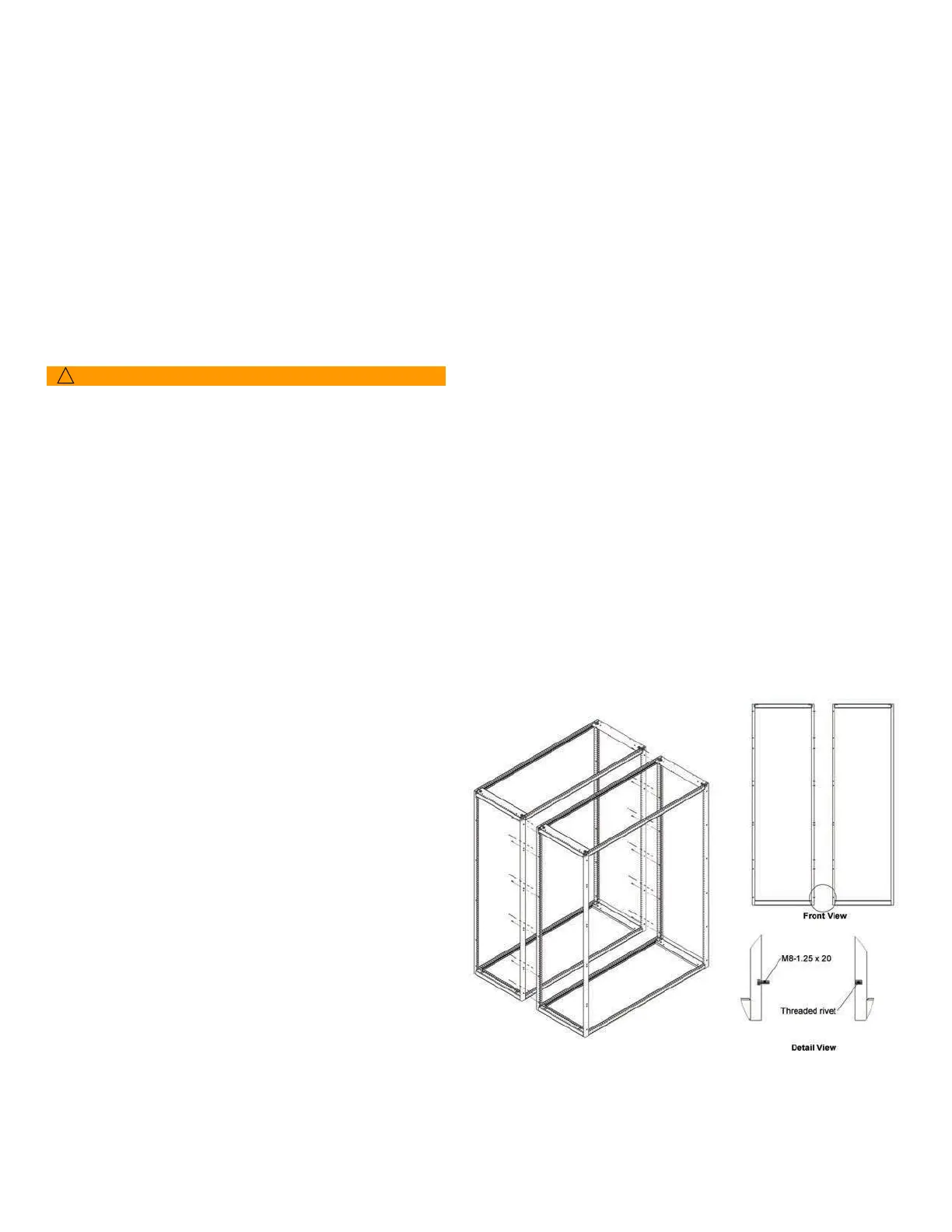

4.4.2. Connect sections

NOTE: Use only the provided fasteners to assemble

the

switchgear.

1. Begin the installation at either the left or the right

end of

the lineup by connecting the frames of the sections

together. The left side of each frame is fitted

with threaded

inserts. Sections are fitted on the right

side with the

necessary rivet nuts. Insert the bolts from the left side of

one frame to the inserts in the

adjoining section to the

right.

Frame connection using spacer bolts

Loading...

Loading...