14

7. INTERNAL ARC CLASSIFICATION (IAC)

During development of all ABB products, focus is put on

personnel safety. This is why the SafeRing/SafePlus portfolio

was designed and tested for a variety of internal arc scenarios

in order to withstand an internal arc of the same current level

as a maximum short circuit current. The tests show that the

metal enclosure of Safering/SafePlus switchgear is able to

protect personnel standing close to the switchgear during an

internal arc fault.

Causes and effects of IAC

An internal arc is a highly unlikely fault, although it can theore-

tically be caused by various factors, such as:

− Insulation defects due to quality deterioration of the

components. The reasons can be adverse environmental

conditions and a highly polluted atmosphere.

− Inadequate training of the personnel in charge of the instal-

lation, leading to incorrect installation of the cables.

− Breakage or tampering of the safety interlocks.

− Overheating of the contact area, e.g. when the connections

are not sufficiently tightened.

− Short circuits caused by small animals that have entered

into the cable compartment (i.e. through cable entrance).

The energy produced by the internal arc causes the following

phenomena:

− Increase of the internal pressure.

− Increase of the temperature.

− Visual and acoustic effects.

− Mechanical stresses on the switchgear structure.

− Melting, decomposing and evaporation of materials.

Tested according to IEC standard 62271-200

The capability of SafeRing/SafePlus switchgear to withstand

an internal arc is proven by the type test according to Inter-

nal arc classification (IAC) as described in the standard IEC

62271-200 as follows:

Accessibility: A, B or C (switchgear)

A=Accessible to authorized personnel only

B=public access

C=not accessible due to installation

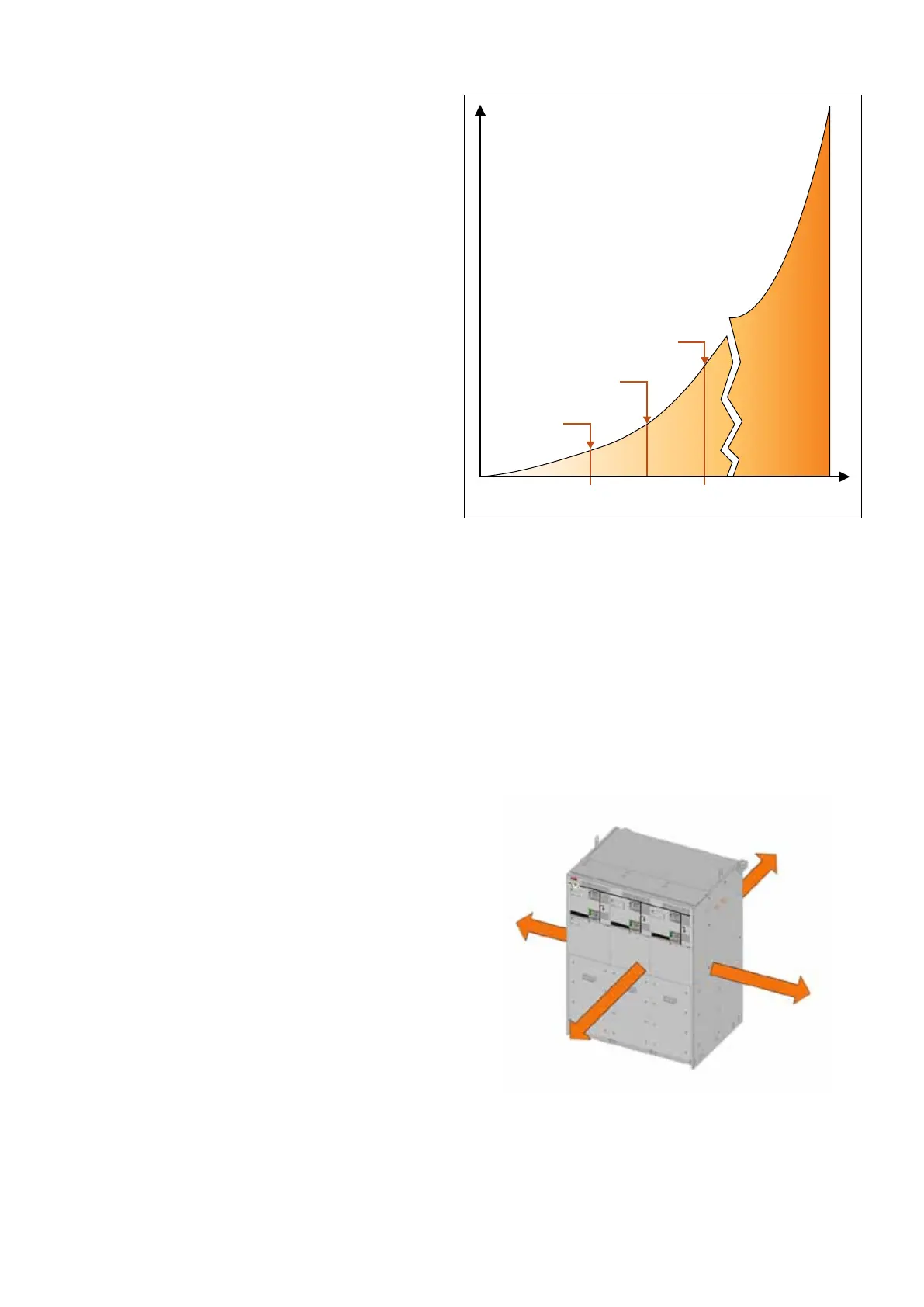

F-Front=Access from the front

L-Lateral=Access from sides

R-Rear=Access from the rear

All test specimens passed the following test criteria according

to the standards:

− Correctly secured doors and covers do not open

− No fragmentation of the enclosure occurs within the time

specified for the test. Projection of small parts, up to an

individual mass of 60 g are accepted

− Arcing does not cause holes in the enclosure of the switch-

gear up to a height of 2 m

− Indicators do not ignite due to the effect of hot gases

− The enclosure remains connected to its earthing point

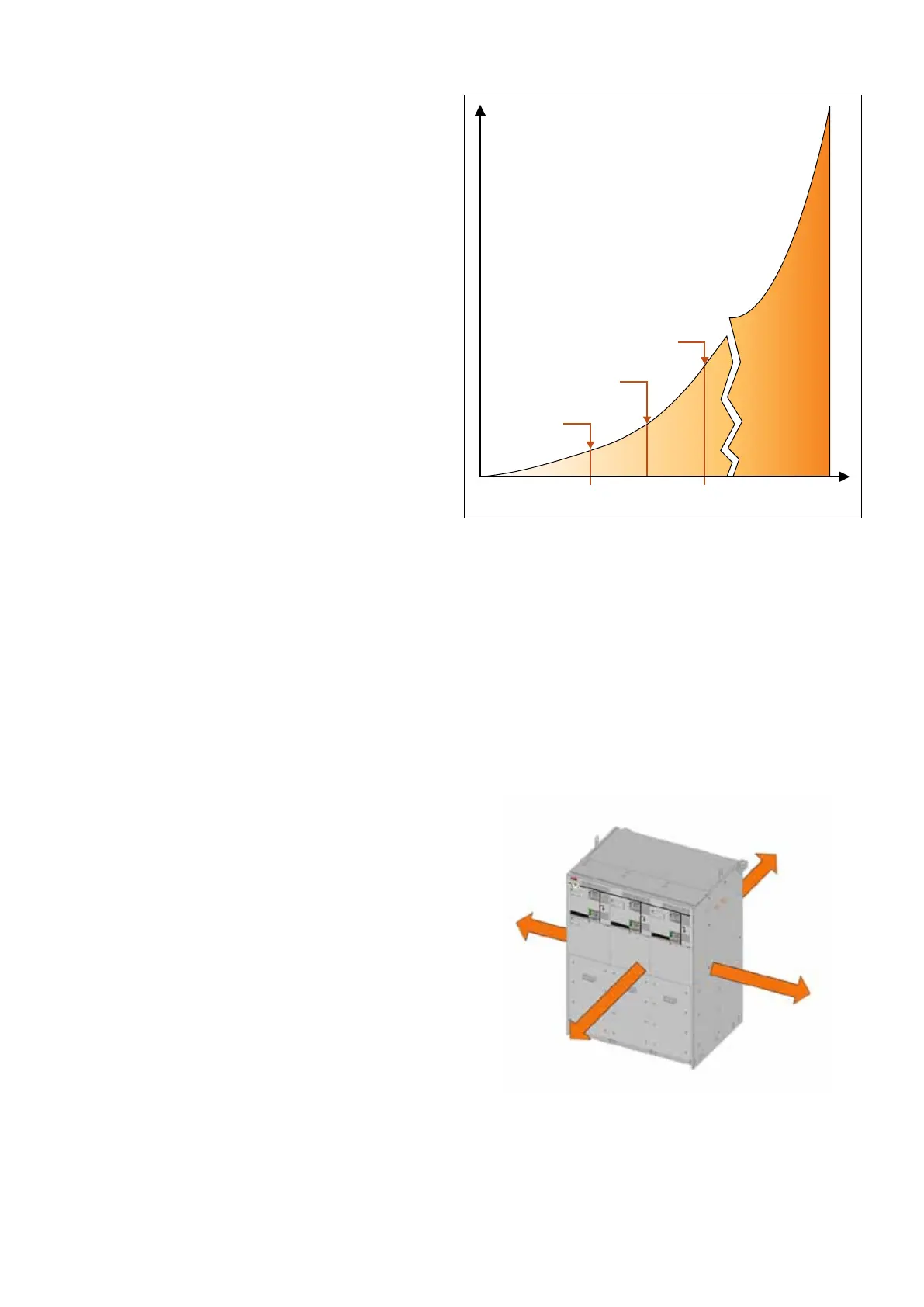

Arc duration and damage caused

Melting of

Steel

Melting of

Copper

Melting of

Cables

0 100 200 500 ms

kA

2

s

R

L

L

F

Loading...

Loading...