20 TTH300 HEAD-MOUNT TEMPERATURE TRANSMITTER | OI/TTH300-EN REV. E

8 Electrical connections

Safety instructions

DANGER

Improper installation and commissioning of the device

carries a risk of explosion.

For use in potentially explosive atmospheres, observe the

information in Use in potentially explosive atmospheres in

accordance with ATEX and IECEx on page 6 and Use in

potentially explosive atmospheres in accordance with FM

and CSA on page 12!

Observe the following instructions:

• The electrical connection may only be established by

authorized specialist personnel and in accordance with

the connection diagrams.

• The relevant regulations must be observed during electric

installation.

• The electrical connection information in the instruction

must be observed; otherwise, the electric IP rating may

be adversely affected.

• Safe isolation of electric circuits which are dangerous if

touched is ensured only if the connected devices satisfy

the requirements of DIN EN 61140 (VDE 0140 Part 1)

(basic requirements for safe isolation).

• To ensure safe isolation, install connection leads separate

from electric circuits which are dangerous if touched, or

implement additional insulation measures.

• Connections must only be established in a dead-voltage

state!

• The transmitter has no switch-off elements. Therefore,

overcurrent protective devices, lightning protection, or

voltage disconnection options must be provided with the

installation.

• The power supply and signal are routed in the same

conductor and should be implemented as a SELV or PELV

circuit in accordance with the relevant standard

(standard version). For the explosion-proof design, the

guidelines in accordance with the Ex standard must be

adhered to.

• You need to check that the available power supply

corresponds to the information on the name plate.

Note

The signal cable wires must be provided with wire end sleeves.

The slotted screws of the connection terminals are tightened

with a size 1 screwdriver (3.5 or 4 mm).

Protection of the transmitter from damage

caused by highly energetic electric

interferences

The transmitter has no switch-off elements. Therefore,

overcurrent protective devices, lightning protection, or voltage

disconnection options must be provided at the plant.

For the shielding and grounding of the device and the

connection cable, observe Pin assignment on page 22.

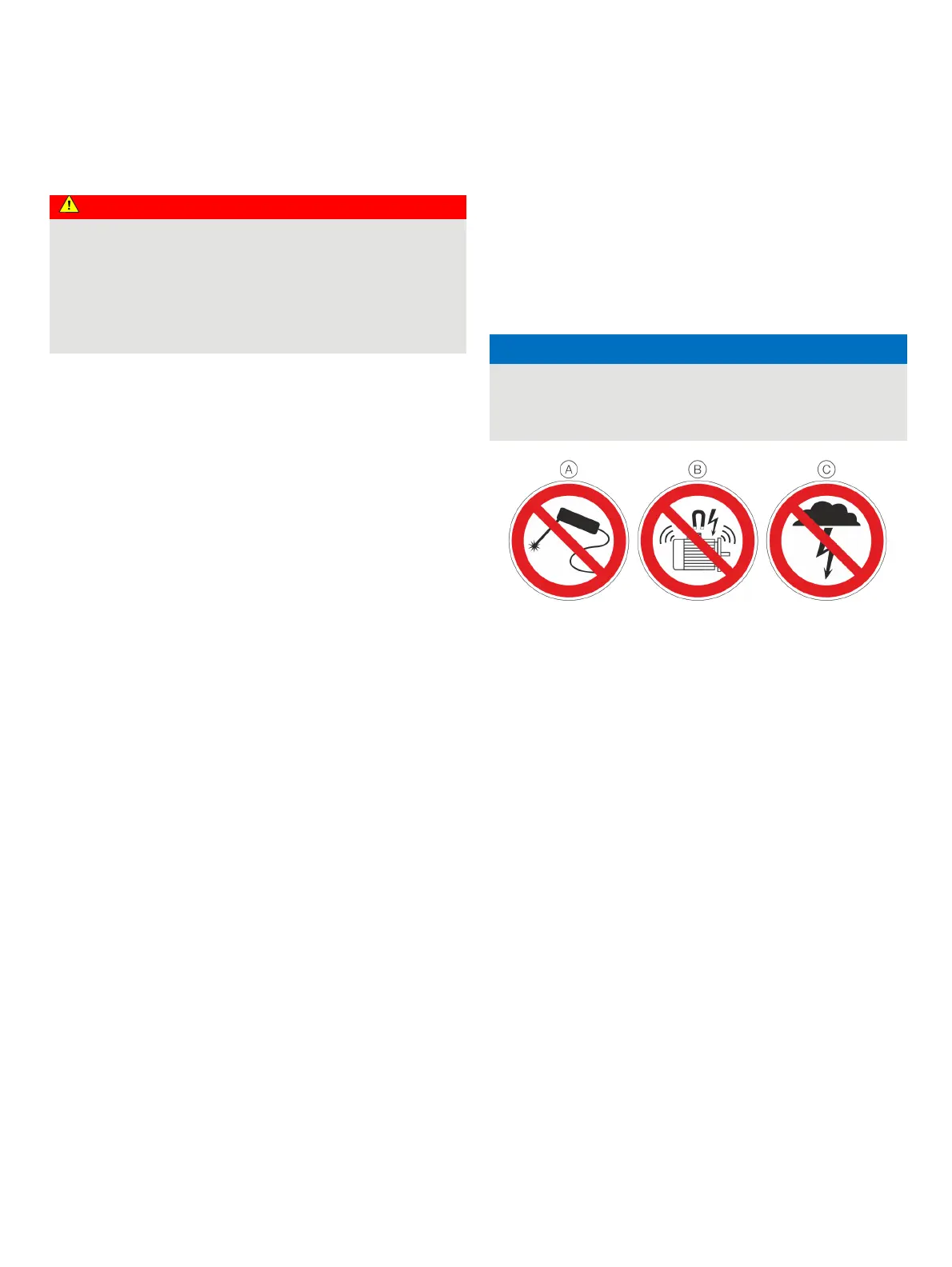

NOTICE

Temperature transmitter damage!

Overvoltage, overcurrent and high-frequency interference

signals on the supply connection as well as sensor connection

side of the device can damage the temperature transmitter.

A Do not weld

B No high-frequency interference signals / switching operations of large

consumers

C No overvoltage due to lightning

Figure 14: Warning signs

Overcurrent and overvoltage can occur through for example

welding operations, switching operations of large electric

consumers, or lightning in the vicinity of the transmitter, sensor,

as well as connector cables.

Temperature transmitters are sensitive devices on the sensor

side as well. Long connector cables to the sensor can encourage

damaging interference. This can already happen if temperature

sensors are connected to the transmitter during installation, but

are not yet integrated into the system (no connection to the

supply isolator / DCS)!

Loading...

Loading...