8.3 Disinfecting and sterilising the Prophypen handpiece

The powder system must imperatively be purged before cleaning, See "It is imperative to purge the Prophypen

handpiece and cord after every use, no matter how short." page 21

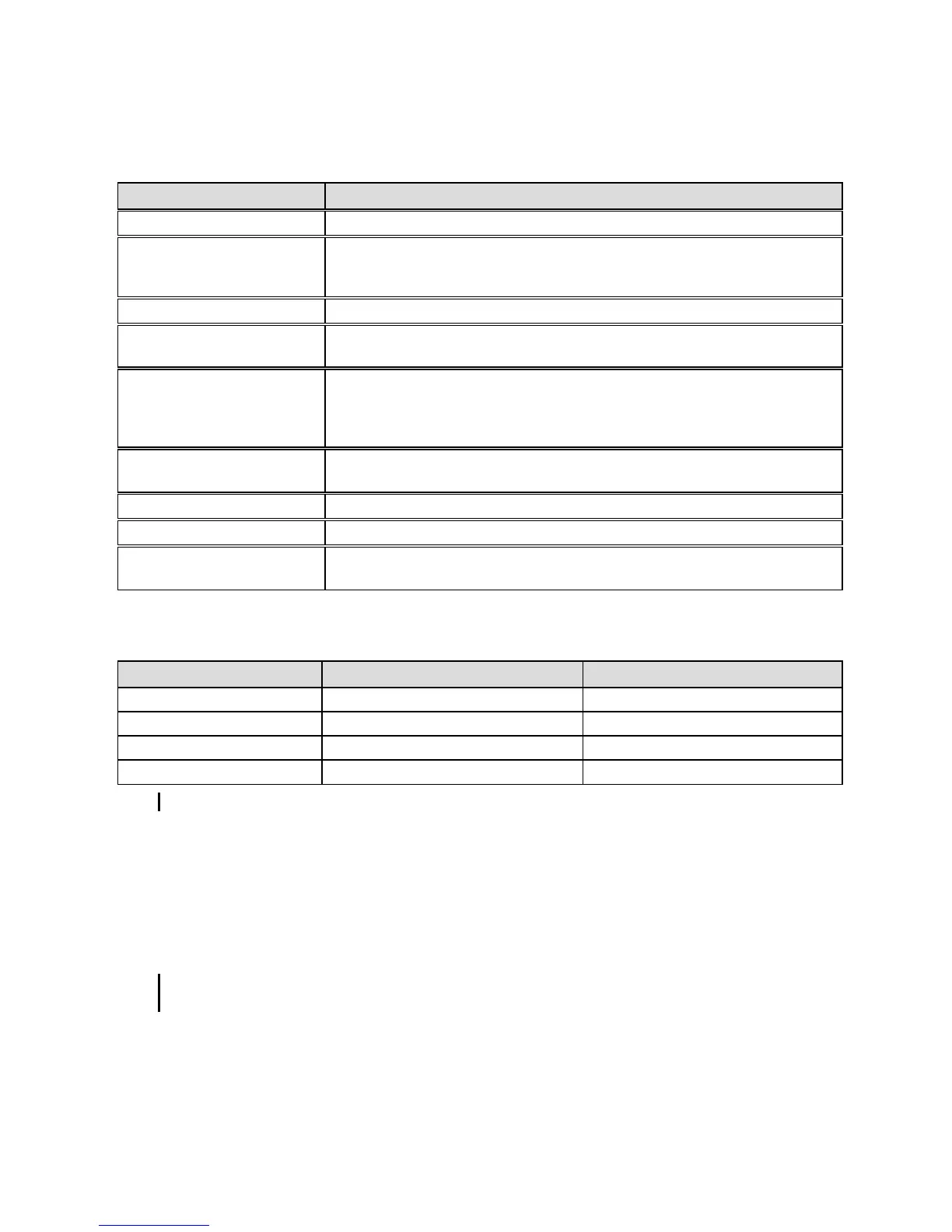

8.3.1 Pre-disinfection and cleaning – Manual method

Minimum duration of step Cleaning instructions

1 minute Rinse in running water at ambient temperature.

2 minutes

Use a soft-bristled brush and a bottle brush to remove most of the contamination.

Use a syringe, a pipette or a water spray with an alkaline or enzymatic cleaning

solution to rinse the handpiece cannulation.

15 minutes Soak in an alkaline cleaner (pH = 7) in an ultrasonic tank.

2 minutes

Rinse in running water. Use a syringe, a pipette or a water spray with an alkaline or

enzymatic cleaning solution to rinse the handpiece cannulation.

4 minutes

Soak in a freshly prepared solution of an alkaline cleaner (ph=7). Clean difficult

parts with a soft brush and a bottle brush.

Use a syringe, a pipette or a water spray with an alkaline or enzymatic cleaning

solution to rinse the handpiece cannulation.

Inspect visually.

Repeat the preceding steps until there is no more visible contamination.

at least 2 minutes Rinse in demineralised water.

Dry using a soft lint-free cloth or medical grade clean compressed air

Inspect visually.

Repeat the preceding steps until there is no more visible contamination.

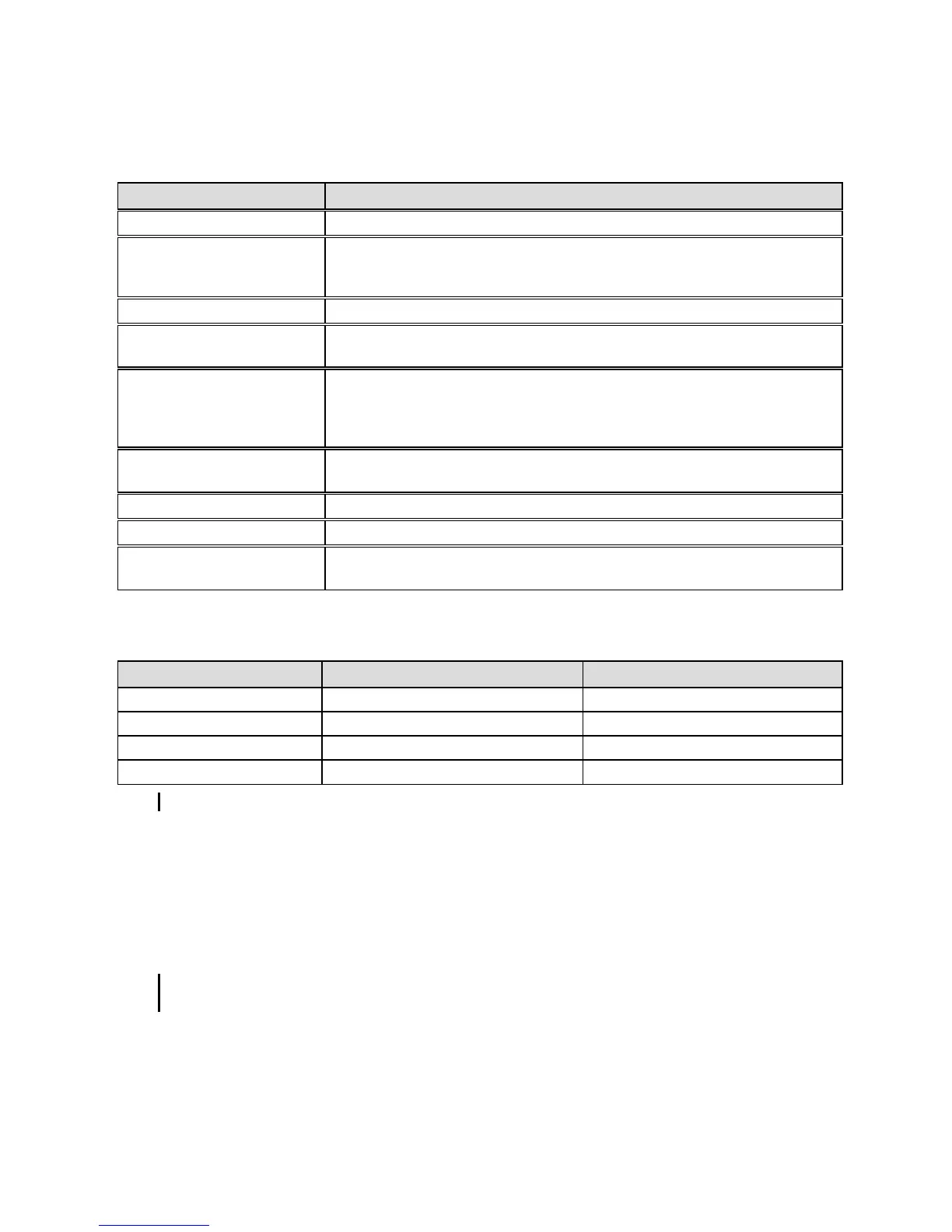

8.3.2 Sterilisation

Unless otherwise specified, non-sterile products can be resterilised using validated steam sterilisation methods (ISO

17665 or national standards). SATELEC, a company of Acteon group recommends the following:

Sterilisation exposure time Sterilisation exposure temperature Drying time

4 minutes 132 °C 15 minutes minimum and 20 minutes

18 minutes 134 °C 15 minutes minimum and 20 minutes

4 minutes 134 °C 15 minutes minimum and 20 minutes

3 minutes 134 °C 15 minutes minimum and 20 minutes

Saturated steam sterilisation with pre-vacuum

The drying times vary from 15 to 60 minutes according to the following criteria:

l the type of packaging material, such as a sterile barrier system or rigid reusable containers;

l steam quality;

l device materials;

l total mass;

l steriliser performance;

l usual practices for the geographical area;

l varying cool-down times.

The manufacturer accepts no responsibility for sterilisation procedures performed by the end user or the

customer that are not performed according to the manufacturer’s recommendations.

Page 22/42 - User Manual|AIRMAX|J11401|V7|(03)|12/2017|ND07EN010G

Loading...

Loading...